Dry sump lubrication system

Content

Any internal combustion engine needs a quality lubrication system. This need is due to the constant operation of the unit parts under conditions of increased mechanical stress (for example, while the engine is running, the crankshaft rotates continuously, and the pistons in the cylinders reciprocate). So that the parts rubbing against each other do not wear out, they need to be lubricated. Engine oil creates a protective film, so that the surfaces do not come into direct contact with each other (for more information on the properties of engine oil and how to choose the right one for the internal combustion engine of your car, read separately).

Despite the presence of an oil film that prevents dry friction of the engine parts, a wear is still formed on them. As a result, small metal particles appear. If they remain on the surface of the part, production on it will increase, and the motorist will have to put the car for overhaul. For this reason, it is extremely important that there is a sufficient amount of lubricant in the sump, with the help of which all components of the power unit are abundantly lubricated. The waste is flushed into the sump and remains in it until it is removed by rinsing or disposal after removing the sump.

In addition to its lubricating properties, the oil also performs the function of additional cooling. Since there is a constant combustion of the air-fuel mixture in the cylinders, all parts of the unit experience serious thermal stress (the temperature of the medium in the cylinder rises to 1000 degrees or more). The engine device includes a large number of parts that need cooling, but due to the fact that they have nothing to do with the cooling system, they suffer from a lack of heat transfer. Examples of such parts are the pistons themselves, connecting rods, etc.

To keep these parts cool and get the right amount of lubrication, the vehicle is equipped with a lubrication system. In addition to the classic design, which is described in another review, there is also a dry sump version.

Let's consider how a dry sump differs from a wet sump, on what principle the system works, and also what are its advantages and disadvantages.

What is dry sump lubricant?

Regardless of the modification of the lubrication system, the principle of operation is basically the same for them. The pump sucks in oil from the reservoir and, under pressure, feeds it through the oil lines to the individual engine components. Some parts are in constant contact with the lubricant, others are abundantly watered with oil mist formed as a result of the active operation of the crank mechanism (for details on how it works, read here).

In the classic system, the lubricant flows naturally into the sump where the oil pump is located. It ensures the movement of oil through the appropriate channels. This type of system is called a wet sump. A dry analogue means an identical system, only it has a separate reservoir (it is not at the lowest point of the unit, but is higher), into which the main pump will pump out lubricant, and an additional oil pump. A second pump is needed to pump lubricant to the engine parts.

In such a system, a certain amount of lubricating fluid will also be in the sump. It is conditionally dry. It's just that in this case, the pallet is not used to store the entire volume of oil. There is a separate reservoir for this.

Despite the fact that the classic lubrication system has proven itself to be low cost maintenance and high reliability of operation, it is not without its drawbacks. An example of this is a punctured pallet when a car goes off-road and hits a sharp stone. Consider in what other conditions a dry sump system is useful.

What is the dry sump system used for?

Most often, a sports car, a certain category of special equipment and some SUVs will be equipped with a similar engine lubrication system. If we talk about SUVs, then it is clear why the oil tank for the internal combustion engine is not located at the lowest point of the car. This is extremely important when fording, when the driver does not see sharp stones under water or when overcoming rough terrain with rocky road surfaces.

What about sports cars? Why does a sports car need a dry sump if it constantly moves on an almost perfectly flat surface? In fact, at high speeds, even minor changes in trajectory can be fraught with abundant sparking from under the car due to the pallet clinging to the road surface. When the driver brakes sharply before entering a turn, the vehicle leans forward, which reduces the ground clearance to critical levels.

But even this is not the most critical for a sports car. When the crankshaft is operating at maximum speed, in the classic design of the lubrication system, most of the lubricant is whipped into an oil mist and supplied to various components of the power unit. Naturally, the level of lubricant in the reservoir is significantly reduced.

Under normal conditions, an oil pump is capable of pumping out oil and creating the pressure required to operate the machinery. However, a sporty way of driving is always associated with the fact that the lubricant remaining in the sump splashes due to the constant rolls of the car. In this mode, the pump cannot operate efficiently and does not suck in enough liquid.

Due to the combination of all of the above factors, the engine may experience oil starvation. Since fast moving parts do not receive the proper amount of lubrication, the protective film on them is quickly removed, resulting in dry friction. In addition, some elements do not receive adequate cooling. All this significantly reduces the working life of the internal combustion engine.

To eliminate all these negative consequences, the engineers developed a dry sump system. As mentioned earlier, its design is somewhat different from the standard version.

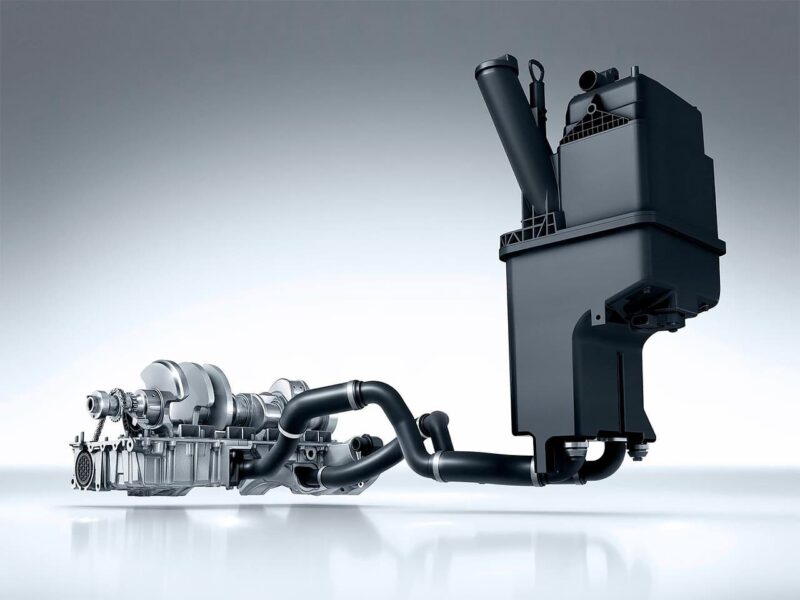

The principle of operation and the device "dry sump"

The oil for lubricating engine parts in such a system is in a reservoir, from which it is pumped out by a pressure pump. Depending on the device, the lubricant can enter the cooling radiator or directly into the motor through the channels intended for this.

After the portion has fulfilled its function (it has lubricated the parts, washed away the metal dust from them, if it has formed, and removed the heat), it is collected in the pan under the action of the force of gravity. From there, the liquid is immediately sucked in by another pump and fed into the reservoir. To prevent small particles washed into the sump from getting back into the engine, at this stage they are retained in the oil filter. In some modifications, the oil goes through a radiator, in which it is cooled, just like antifreeze in CO.

At this stage, the loop is closed. Depending on the design of the system, there may be several suction modules in it, which accelerate the collection of oil into the tank. Many dry sump vehicles have additional equipment to stabilize the lubrication of the unit. Let's take a closer look at how the lubricating system works, and what function each element performs in it.

Engine dry sump system

In modern cars, different modifications of dry sump engine lubrication can be used. Regardless, their key elements are:

- Additional reservoir for grease;

- A pump that creates a head in the line;

- A pump that draws oil out of the sump (identical to the classic version in a wet sump);

- A radiator through which oil passes, moving from the sump to the tank;

- Thermal sensor for lubricant;

- A sensor that records the oil pressure in the system;

- Thermostat;

- A filter identical to that used in classic systems;

- Reducing and bypass valve (depending on the system model, their number may differ).

The additional oil reservoir can be of different shapes. It all depends on how the engine compartment is organized in a particular car model. Many tanks have multiple baffles inside. They are needed to soothe the lubricant while the vehicle is moving, and it does not foam.

During operation, the oil pump, along with the lubricant, partially sucks in air. To prevent overpressure in the line, there is a vent in the tank that has the same purpose as the crankcase vent.

It also has a temperature sensor and a pressure sensor in the line. So that the driver can notice the lack of lubricant in time, there is a dipstick in the tank with which the level in the tank is checked.

The advantage of the additional reservoir is that the automaker can organize the engine compartment in its own way. This allows the weight of all mechanisms to be distributed so as to improve the handling in sports cars. In addition, the tank can be positioned in the engine compartment so that the lubricant is blown into it while driving, and additional cooling is provided.

The oil delivery pump is usually located slightly below the oil tank. This installation method makes his job a little easier, since he does not have to spend energy to pump out the liquid - it enters his cavity under the influence of gravity. A pressure reducing valve and a bypass valve are needed in the system to control the oil pressure.

The role of the evacuation pump is identical to a similar mechanism that is installed in any lubrication system of a 4-stroke internal combustion engine (for the differences between four-stroke and two-stroke engines, read here). There are several modifications of such blowers, and in their design they differ from the pumps installed for the additional oil tank.

Depending on the motor model, there may be several pumping modules. For example, in a unit with a V-shaped cylinder block design, the main pump has an additional outlet that collects the used lubricant from gas distribution mechanism... And if the engine is equipped with a turbocharger, then an additional pumping section will also be installed near it.

This design accelerates the accumulation of grease in the main reservoir. If it would drain naturally, there is a high probability that the level in the reservoir would be too low and the engine would not receive enough oil.

The operation of the supply and discharge pumps is connected to the crankshaft. While it is spinning, the blowers also work. There are, but rarely enough, modifications that work from a camshaft. The torque from the crankshaft to the pump mechanism is transmitted either through a belt or through a chain.

In this design, it is possible to install the required number of additional sections that will operate from one shaft. The advantage of this arrangement is that in the event of a breakdown, the pump can be dismantled from the motor without interfering with the design of the unit itself.

Although the drain pump has the same operating principle and design as its wet sump counterpart, it has been modified so that its performance is not lost, even when sucking in foamed oil or partly air.

The next element that is not present in wet sump systems is the radiator. Its task is the same as that of the heat exchanger of the cooling system. It also has a similar design. Read more about this. in another review... Basically, it is installed between the injection oil pump and the internal combustion engine, but there are also installation options between the evacuation pump and the tank.

A thermostat in the lubrication system is needed in order to prevent it from prematurely cooling when the engine warms up. The cooling system has a similar principle, which is described in detail. here... In short, while the internal combustion engine is warming up (especially during the cold period), the oil in it is thicker. For this reason, it does not need to be cooled in order for it to flow and to improve the lubrication of the unit.

As soon as the working medium reaches the desired temperature (you can find out about what the operating temperature of the engine should be from another article), the thermostat opens and oil flows through the radiator for cooling. This ensures better heat dissipation from hot parts that are not in contact with the cooling jacket of the motor.

Pros and cons of a dry sump system

The very first benefit of dry sump systems is to provide stable lubrication regardless of the driving mode of the vehicle. Even if the vehicle overcomes a long rise, the motor will not experience oil starvation. Since during extreme driving it is more likely that the motor will overheat, this modification provides better cooling of the unit. This factor is of fundamental importance for ICE equipped with a turbine (for details on the device and principle of operation of this mechanism, read separately).

Due to the fact that the oil is not stored in a sump, but in a separate reservoir, the design of the oil receiver is much smaller, thanks to which the designers manage to reduce the clearance of the sports car. The bottom in such cars is most often flat, which has a positive effect on the aerodynamics of transport (what affects this parameter is described here).

If the sump is punctured during the ride, the grease will not spill out of it, as in the case of the classic lubrication system. This gives an advantage in emergency repairs on the road, especially if the SUV has suffered such damage very far from the nearest auto parts store.

The next plus of a dry sump is that it makes the work of the power unit itself a little easier. So, when the car has been standing in the cold for a long time, the oil in the tank becomes thicker. At the time of starting a power unit with a classic lubrication system, the crankshaft needs to overcome not only the resistance in the cylinders on the compression stroke (when the engine is running, this force is partially facilitated by the inertial force), but also the resistance of the thick oil (the crankshaft in this case is in oil bath). In a dry sump, this problem is eliminated, since all the lubricant is separate from the crankshaft, which makes the engine start faster.

During rotation, the crankshaft does not work in the lubrication system like a mixer. Thanks to this, the oil does not foam and does not lose its density. This provides a better quality film on the contact surfaces of the unit parts.

In a dry sump, the lubricant is less in contact with crankcase gases. Due to this, the rate of the oxidative reaction is reduced, which increases the resource of the substance. Small particles do not have time to settle in the oil pan, but are immediately removed to the filter.

Since oil pumps in most system modifications are installed outside the unit, in the event of a breakdown, there is no need to disassemble the internal combustion engine in order to carry out the necessary procedures. These factors allow us to conclude that the unit with a dry crankcase is more reliable and efficient compared to the classic analogue.

Despite such a number of positive aspects, the dry sump system has a number of serious disadvantages. Here are the main ones:

- Firstly, due to the presence of additional mechanisms and parts, the maintenance of the system will be more expensive. In some cases, the complexity of the repair is associated with the operation of the electronics (there are varieties in which the lubrication of the unit is controlled by a separate controller).

- Secondly, in comparison with the classical system, this modification requires a larger amount of oil in a motor with an identical volume and design. This is due to the presence of additional mechanisms and elements, the most voluminous of which is the radiator. The same factor affects the weight of the car.

- Thirdly, the price of a dry sump motor is much higher than that of its classic counterpart.

In conventional production vehicles, the use of a dry sump system is not reasonable. Such vehicles are not operated even under extreme conditions, in which the effectiveness of such a development can be assessed. It is more suitable for rally racing cars, circuit races such as NASCAR and other types of motorsport. If there is a desire to slightly improve the characteristics of your vehicle, then installing a dry sump system will not give a noticeable effect without serious modernization for harsh operating conditions. In this case, you can limit yourself to chip tuning, but this is a topic for another article.

In addition, for those who are interested in the topic of auto-tuning, we suggest watching this video, which discusses in detail the dry sump system and some of the subtleties associated with its installation:

Questions and answers:

What does dry sump mean? This is a type of engine lubrication system that has a separate reservoir that stores the engine oil. Most modern cars are equipped with a wet sump system.

What is a dry sump for? The dry sump system is intended primarily for those cars that partly move on steep slopes. In such a system, the motor always receives proper lubrication of the parts.

What are the design features of dry sump lubrication systems? In a dry sump, oil flows into a sump, and from there the oil pump sucks it in and pumps it into a separate reservoir. In such systems, there are always two oil pumps.

How does the engine lubrication system work? In such systems, the motor is lubricated in the classical way - oil is pumped through channels to all parts. In a dry sump, sump breakdown can be repaired without losing all of the oil.