What is a variable geometry turbo and how does it work?

Content

If you need more responsiveness from your turbo without sacrificing peak power, a variable geometry turbo may be just what you need. Here we will tell you what VGT is and how it works, as well as its advantages over a fixed geometry turbocharger.

Turbochargers are great because they absorb unwanted energy and use it to increase engine power. The Variable Geometry Turbocharger is an advanced version of this technology that provides a number of benefits along with increased complexity. Thanks to a video made by KF Turbo on Instagram, we got a closer look at what makes a variable geometry turbo so special.

How does a variable geometry turbocharger work?

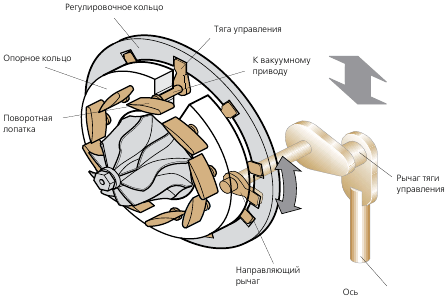

The video shows us the inside of a typical variable vane turbocharger. It consists of a set of blades arranged around the exhaust turbine, the angle of which is controlled by an actuator. For example, there are other designs with paddles that move up and down; they are more common in heavier machines such as trucks or other large vehicles.

What is the difference between a fixed geometry turbocharger?

In a conventional fixed geometry turbocharger, the exhaust gases pass through a turbine and spin it, which spins an attached compressor that creates boost for the engine. At low RPM, the engine does not generate enough exhaust flow to spin the turbine and create significant levels of boost. At this point, the system is said to be below the boost threshold.

Once the engine reaches RPM high enough to generate thrust, it still takes some time to spin the turbine up to the right speed; this is known as turbo lag. Turbo lag and boost threshold are higher for larger turbos that need more power to spin. However, these higher flow turbines are capable of generating more power. It's a compromise, like so many other things in engineering.

What is the advantage of a variable geometry turbocharger?

A variable geometry turbocharger seeks to change this by adding vanes or other elements that functionally change the geometry of the turbine system. In a rotating vane turbocharger like the one shown here, the vanes remain largely closed at low engine speeds, restricting the flow of exhaust gases to the vanes. This limitation increases the flow rate, which helps the exhaust gases to accelerate the turbine faster. This lowers the boost threshold and reduces turbo lag.

RPM penalty

However, having such a limitation would be a severe penalty at higher RPMs, when the engine needs to pump more exhaust gases to generate power. In this state, the vanes open to allow as much exhaust gas as possible to pass through the turbocharger, avoiding restriction that would increase back pressure and reduce power.

Why is a variable geometry turbocharger more convenient?

So the variable geometry turbo engine is truly the best of both worlds. The VGT can put out more power without the usual trade-offs of high boost threshold and turbo lag that typically come with a big turbo setup. The overall efficiency is also improved and in some cases the blades can even be used as an engine brake. The video below is a great explanation of how this technology works, with a helpful whiteboard diagram.

**********

: