abs sensor honda fit

Content

ABS sensors play an important role in the operation of the vehicle's braking system - the braking efficiency and the smooth operation of the unit as a whole depend on them. Sensor elements transmit data on the degree of rotation of the wheels to the control unit, and the control unit analyzes the incoming information, building the desired algorithm of actions. But what to do if there are doubts about the health of the devices?

Signs of device malfunction

The fact that the ABS sensor is faulty is signaled by an indicator on the instrument panel: it lights up when the system is turned off, goes out even with the slightest malfunction.

Evidence that the ABS has stopped "interfering" with the brakes:

- The wheels constantly lock up under heavy braking.

- There is no characteristic knocking with simultaneous vibration when pressing the brake pedal.

- The speedometer needle lags behind acceleration or does not move at all from its original position.

- If two (or more) sensors on the instrument panel fail, the parking brake indicator lights up and does not go out.

What should I do if the ABS indicator on the dashboard of the car does not behave quite correctly? You should not immediately change the sensor, you first need to check the devices; this procedure can be performed independently, without resorting to the services of highly paid masters.

Health check methods

To determine the state of the part, we perform a series of actions to diagnose it, going from simple to complex:

- Let's check the fuses by opening the block (inside the passenger compartment or in the engine compartment) and inspecting the corresponding elements (indicated in the repair / operation manual). If a burnt component is found, we will replace it with a new one.

- Let's take a look and check:

- connector integrity;

- wiring for abrasions that increase the risk of a short circuit;

- contamination of parts, possible external mechanical damage;

- fixing and connecting to the ground of the sensor itself.

If the above measures do not help identify a device malfunction, it will have to be checked with devices - a tester (multimeter) or an oscilloscope.

Tester (multimeter)

For this method of diagnosing the sensor, you will need a tester (multimeter), instructions for operating and repairing the car, as well as PIN - wiring with special connectors.

Tester (multimeter) - a device for measuring the parameters of electric current, combining the functions of a voltmeter, ammeter and ohmmeter. There are analog and digital models of devices.

To obtain complete information about the performance of the ABS sensor, it is necessary to measure the resistance in the device circuit:

- Raise the vehicle with a jack or hang it on a lift.

- Remove the wheel if it obstructs access to the device.

- Remove the system control box cover and disconnect the connectors from the controller.

- We connect the PIN to the multimeter and the sensor contact (the rear wheel sensor connectors are located inside the passenger compartment, under the seats).

The readings of the device must correspond to the data specified in the manual for the repair and operation of a particular vehicle. If the resistance of the device:

- below the minimum threshold - the sensor is faulty;

- approaches zero - short circuit;

- unstable (jumping) at the moment of tightening the wires - a violation of the contact inside the wiring;

- endless or no readings - cable break.

Attention! The resistance of the ABS sensors on the front and rear axles is different. The operating parameters of the devices are from 1 to 1,3 kOhm in the first case and from 1,8 to 2,3 kOhm in the second.

How to check with an oscilloscope (with wiring diagram)

In addition to self-diagnosis of the sensor with a tester (multimeter), it can be checked with a more complex device - an oscilloscope.

The device examines the amplitude and time parameters of the sensor signal

An oscilloscope is a device that studies the amplitude and time parameters of a signal, which is designed to accurately diagnose pulse processes in electronic circuits. This device detects bad connectors, ground faults and wire breaks. The check is carried out by visual observation of the vibrations on the screen of the device.

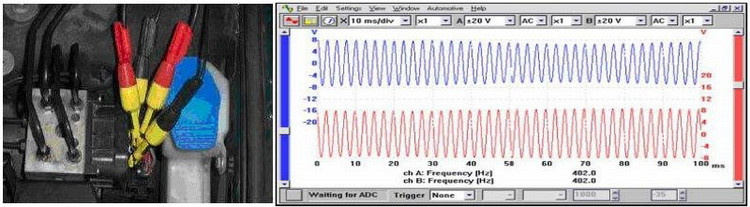

To diagnose the ABS sensor with an oscilloscope, you must:

- Fully charge the battery in order to observe the voltage drop (spikes) on the connectors or leads during the measurement.

- Locate the touch sensor and disconnect the top connector from the part.

- Connect the oscilloscope to a power outlet.

Connecting the device to the ABS sensor connector (1 - gear rotor; 2 - sensor)

The status of the ABS sensor is indicated by:

- the same amplitude of the signal fluctuation during the rotation of the wheels of one axle;

- the absence of amplitude beats when diagnosing with a sinusoidal signal of a lower frequency;

- maintaining a stable and uniform amplitude of signal oscillations, not exceeding 0,5 V, when the wheel rotates at a frequency of 2 rpm.

Please note that the oscilloscope is a rather complicated and expensive device. Modern computer technology makes it possible to replace this device with a special program downloaded from the Internet and installed on a regular laptop.

Checking a part without instruments

The easiest way to diagnose a hardwareless device is to check the solenoid valve on the induction sensor. Any metal product (screwdriver, wrench) is applied to the part in which the magnet is installed. If the sensor does not attract it, it is defective.

Most modern automotive anti-lock braking systems have a self-diagnosis function with error output (in alphanumeric coding) on the on-board computer screen. You can decipher these symbols using the Internet or the machine's instruction manual.

What to do if a breakdown is detected

What to do with the ABS sensor if a malfunction is detected? If the problem is the device itself, it will have to be replaced, but in the case of electrical wiring, you can fix the problem yourself. To restore its integrity, we use the “welding” method, carefully wrapping the joints with electrical tape.

If the ABS light comes on on the dashboard, this is a clear sign of a sensor problem. The described actions will help to identify the cause of the breakdown; however, if knowledge and experience are not enough, it is better to contact the car service masters. Otherwise, illiterate diagnostics of the condition, coupled with improper repair of the device, will reduce the effectiveness of the anti-lock braking system and may lead to an accident.

How to check the ABS sensor yourself

The effectiveness of the braking system of a car largely depends on the skills of the driver, on his professional skills. But, in this case, various auxiliary systems and components also serve as a significant help, allowing you to create all the necessary conditions for safe driving.

A special role in this case is played by an electronic mechanism that prevents the wheels from blocking - an anti-lock braking system. In fact, the range of action of the presented system goes far beyond its direct purpose, which is best expressed in the ability to control the vehicle in various operating modes.

One of the most important components of this system is the ABS sensor. The effectiveness of the entire braking process depends on its proper operation. Let's get to know him better.

The principle of operation of the ABS sensor

Any diagnostic measures will not be effective if the driver has no idea about the principles of operation of the unit or element of the system under study. Therefore, before the stage involving surgical intervention in the operation of this device, it is first necessary to study the principle of its operation.

What is an ABS sensor?

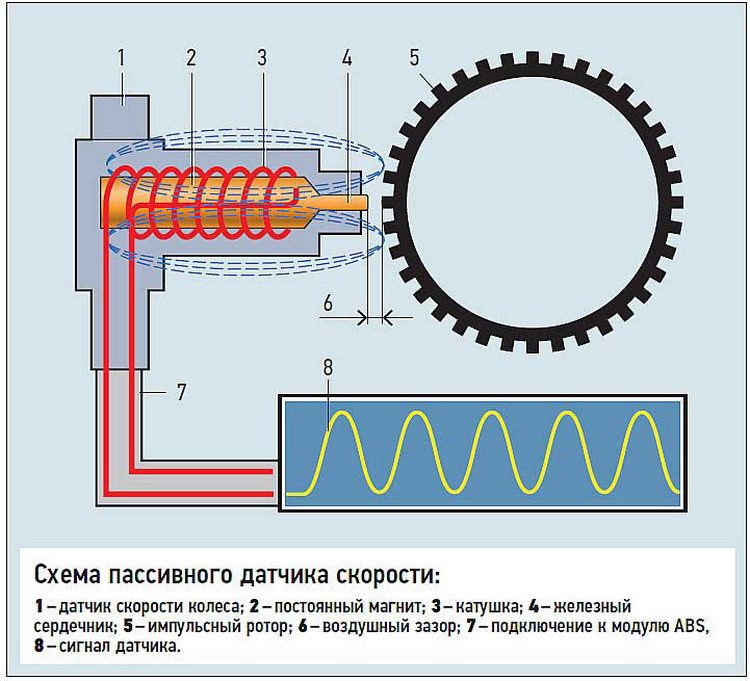

Let's start with the fact that this simple device can be found on each of the 4 axles of the car. One solenoid is in a sealed plastic case.

Another important element of the sensor is the so-called impulse ring. The inner side of the ring is made in the form of a serrated thread. It is installed at the rear of the brake disc and rotates with the vehicle's wheel. At the end of the solenoid core is a sensor.

The main performance of this system is based on reading the electrical signal from the throttle directly to the reader of the control unit. So, as soon as a certain torque is transmitted to the wheel, a magnetic field begins to appear inside the electromagnet, the magnitude of which increases in proportion to the increase in the speed of rotation of the drive ring.

As soon as the rotation of the wheel reaches the minimum number of revolutions, the pulse signal from the presented sensor begins to flow to the processing device. The impulse nature of the signal is due to the ring gear of the impulse ring.

Further operation of the ABS hydroblock depends on the frequency of the signal recorded in the receiving device. The driving elements of the brake force hydraulic distributor are solenoids, a hydraulic pump and valve mechanisms.

Depending on the strength of the signal entering the valve body, valve mechanisms with electromagnetic control come into operation. In case of blocking the wheels, the hydraulic group, taking into account the corresponding signal, reduces the pressure in this brake circuit.

At this moment, the hydraulic pump is activated, pumping the brake fluid back into the GTZ reservoir through the open bypass valve. As soon as the driver reduces the effort on the pedals, the bypass valve closes, and the pump, in turn, stops working.

At this time, the main valve opens and the pressure in this brake circuit returns to normal.

The presented modification of the ABS peripheral element is the most common and is used on most domestic and foreign cars.

Due to the relative simplicity of this design, the elements of the system have a high resistance to mechanical wear and good performance.

If the part is out of order, then it is not so difficult to carry out the manipulations described below. It is easier to buy and replace the sensor with a new one.

Signs of device malfunction

Despite the fact that the presented device, as a rule, is designed for uninterrupted operation during long-term operation, various failures and malfunctions may occur during its operation.

For visual control of the system operation, an emergency lamp is used on the instrument panel of the car. It is he who, first of all, indicates various kinds of violations of the system caused by a number of factors.

The cause for concern in this case may be that the control lamp does not go out for a long time after turning the key to the short circuit position, or there is no warning while driving.

The problems that caused this behavior of the sensor can be very diverse.

Consider a number of signs that will later help to identify the cause of the failure of a particular node of the system:

- the ABS light on the dashboard is on for a long time or does not go out at all;

- excessive force when pressing the brake pedal;

- the brake pedal stops responding to your pressing;

- block the wheels when you sharply press the brake pedal.

ABS systems of earlier versions, as a rule, were not equipped with a specialized indication of the operation of the system. In this case, its role was performed by the control lamp of the engine control.

How to diagnose the ABS system

Diagnostic measures that involve checking the ABS system are usually carried out using special equipment. One of them is the so-called diagnostic adapter. To connect it, the manufacturer provides a special diagnostic connector.

The system test starts when the ignition is switched on. The essence of such a check is that using the adapter you can detect the presence of a particular system error. Each error is assigned a specific code, which makes it possible to judge the malfunction of a particular node or element of the system.

However, it should be noted that in most cases, diagnostic adapters of the budget segment do not scan the entire system, but only the engine. Therefore, we recommend using a fully diagnostic scanner.

For example, we can enable Korean-made Scan Tool Pro Black Edition. Having a 32-bit chip on board, this scanner is able to diagnose not only the engine, but also other vehicle components (gearbox, transmission, ABS auxiliary systems, etc.) and at the same time has a fairly affordable price.

This multi-brand scanner is compatible with most vehicles since 1993, showing real-time operation of all available sensors, vehicle VIN, mileage, ECU version, etc.

The device is able to measure the performance of various systems for stability over certain periods of time and store the obtained data on any device based on iOS, Android or Windows.

Diagnostics and preventive measures that make it possible to judge the performance of the system elements are carried out in specialized service centers. However, this task can be performed in a garage.

So, all that is needed to diagnose the ABS sensor is the minimum set of equipment, which includes: a soldering iron, multimeter, heat shrink and repair connectors.

The verification algorithm consists of the following steps:

- wheel lift;

- disassemble the control unit and controller outputs;

- connection of repair connectors to sensors;

- measure resistance with multimeter

If the sensor has not failed, the ohmmeter will show a resistance of about 1 kOhm. This value corresponds to the operation of the sensor at rest. As the wheel rotates, the readings should change. This will point to his fix. If there is no change in readings, the sensor is out of order.

It should be noted that due to various modifications of the sensors, the parameters of their operation may vary. Therefore, before condemning the sensor, you should first familiarize yourself with its operating range, and only then draw conclusions about its serviceability.

Also, in the event of a malfunction of the ABS, it is necessary to make sure that the underwater cables are not damaged. If a wire break is detected, it is necessary to “solder”.

Also, do not forget that the repair contacts must be connected with the correct polarity. Although in most cases protection is triggered by incorrect connection, this should not be done. To facilitate the task, it is best to pre-mark the corresponding cables with a marker or insulating tape.

Checking with a tester (multimeter)

The performance of the sensor can also be diagnosed using a voltmeter. The entire sequence of operations completely copies the previous algorithm with only one difference. To obtain the desired result, it is necessary to create conditions under which the wheel rotates at a frequency equal to 1 rpm.

At the outputs of a working sensor, the potential difference will be approximately 0,3 - 1,2 V. As the wheel speed increases, the voltage should increase. It is this fact that will indicate the working condition of the ABS sensor.

Checking the operation of the ABS sensor is not limited to this. There are a couple of the most effective tricks that will help eliminate various malfunctions of the ABS system.

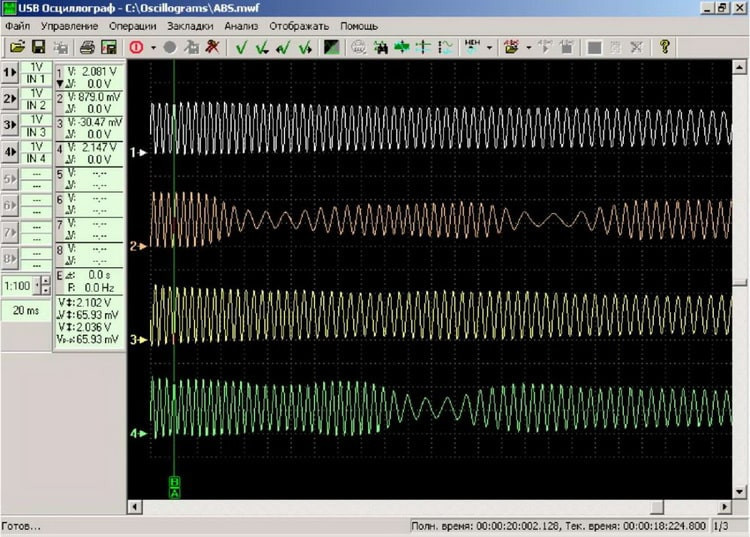

Oscilloscope

Among other things, using an oscilloscope, you can diagnose interruptions in the operation of the ABS sensor. It should be noted that the use of the presented device requires certain skills. If you are an avid radio amateur, it will not be difficult for you to resort to such diagnostics. But for a simple layman, this can cause a number of difficulties. Let's start with the fact that this device will cost you dearly.

Among other things, its use is more justified in a specialized service. However, if by some miracle this extravagant device ended up in your garage, it will be a great help for various diagnostic measures.

The oscilloscope displays an electrical signal. The amplitude and frequency of the signal are displayed on a special screen, which gives a clear idea of the operation of a particular element of the system.

In this case, the principle of checking the condition of the ABS sensor will be based on a comparative analysis of the results obtained. So, the whole procedure at the initial stage is similar to that carried out earlier with a multimeter, only instead of a tester, an oscilloscope should be connected to the sensor outputs.

The diagnostic procedure is as follows:

- rotate the suspension wheel at a constant frequency of about 2-3 rpm;

- set the oscillation amplitude value on the oscilloscope screen.

As soon as readings are taken from one sensor, it is necessary to perform all the same actions with a sensor installed on the opposite side of the same axis.

The results obtained should be compared and appropriate conclusions drawn:

- with relatively equal readings, the sensors can be considered repairable;

- the absence of an abrupt phenomenon when a smaller sinusoidal signal is established indicates that the sensor is in good condition;

- maintaining a stable amplitude with a maximum value not exceeding 0,5 V at a given speed: the sensor serves faithfully.

A good alternative to an expensive device can be a special application with which you can perform all diagnostic actions using a regular laptop.

Checking the sensor without instruments

ABS sensor diagnostics can be carried out without the help of various recording devices. To do this, you only need a wrench or a flathead screwdriver.

The essence of the proof is that when a metal object touches the core of an electromagnet, it must be attracted to it. In this case, you can judge the health of the sensor. If not, then there is every reason to believe that the sensor is dead.

How to fix the found faults

After the diagnostic measures have been successful and the problem has been found, it becomes necessary to remove the failed element from the system. Whether it is an ABS sensor or a boost ring, there is no need to talk about restoring its performance.

In this case, they usually need to be replaced. An exception may be the case when the working surface of the sensor is simply contaminated during long-term operation. To do this, it will be enough to clean it of oxides and dirt particles. As cleaning agents, it is desirable to use a regular soap solution. The use of chemicals is strongly discouraged.

If the control unit became the cause of the failure, then its resuscitation in some cases can cause serious difficulties. However, you can always open up and visually assess the scale of the disaster. Disassembly of the cover must be done carefully so as not to damage the working elements.

It often happens that as a result of vibration, the contacts of one of the terminals simply lose their rigidity. To re-weld them to the plate, it is not necessary to have seven spans on the forehead. To do this, it is enough to get hold of a good pulse welding machine or welding station.

When soldering, it is important to remember that the insulator of the ceramic block is very sensitive to overheating. Therefore, in this case, care must be taken that it does not have an increased thermal effect.