Subaru Forester knock sensor

Content

The pistons in an internal combustion engine move due to the combustion of the fuel mixture in the mixture. The process has a detonation character, therefore, even a slight decrease in its strength, frequency, a significant increase in the wear parameters of the motor, power system. Detonation detonation (DD) is a regular part of a car, wear development at Subaru and Soviet Forester.

What is a knock sensor: functions and task

The twin pistons move emissions from flash fires, the high force of which has a high frequency in the working compartment. The limit of excess power, such powers of detonation cycles, at which they become destructive for the system, is very thin. Its violation does not necessarily mean that a breakdown occurred soon, but the wear of the motor and the construction of structures with it will accelerate

The exclusion of non-optimal signs of ignition of a combustible in a mixture with a deviation from the norm by adjustment - an obvious control unit (ECU). The setting will not be carried out if the system does not “know” about detonation - it is to monitor its occurrence that the knock sensor (DD, knock sensor) serves. Accordingly, the correctness of its operation depends on the correctness of the settings in the entire described system, the quality of the power unit, resources and its nodes.

What does DD look like?

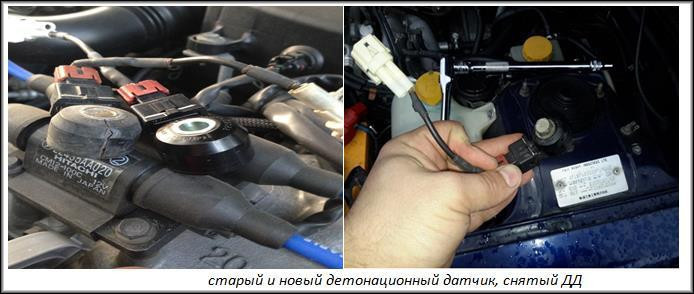

The Subaru Forester knock sensor, like most models of this brand, is a round torus. On the side, it is equipped with a terminal for connecting to the electrical control unit of the internal combustion engine. In the center is a hole for mounting. A piezoelectric element is installed in the intrafunctional segment of the sensor, which reacts to vibration by creating a small voltage and a given frequency.

The computer constantly analyzes the pulses coming from the sensors - If there is a deviation from normal measurements, an assessment of the appearance of detonation Further, the control module, according to the programmed program, ensures the correction of the internal combustion engine, Eliminating non-optimal ignitions of the Fuel Mixture.

Where is the knock sensor located?

The place for DD is determined by the designers so that effective sensitivity is achieved, which increases the accuracy of detonation detection even at the initial stages of analysis.

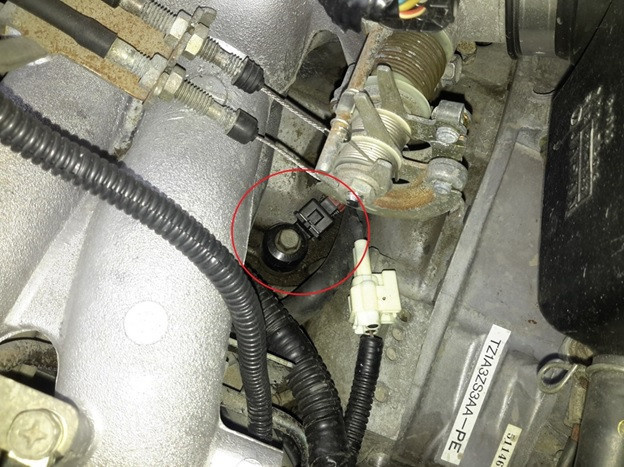

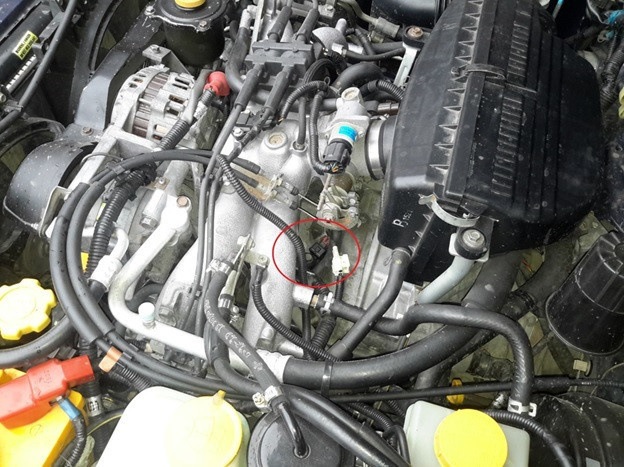

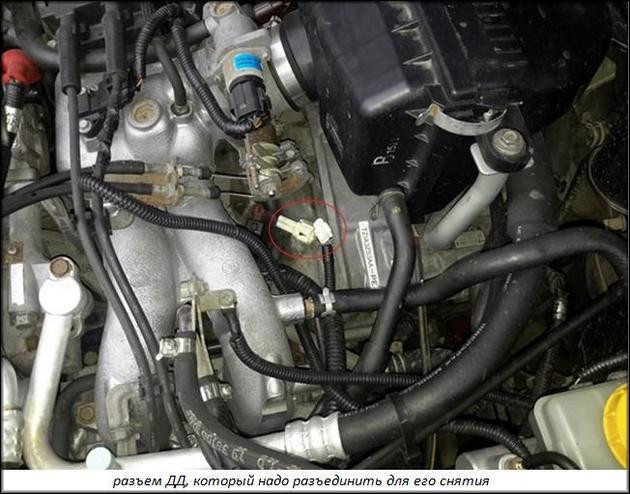

The location of the knock sensor is between the air filter box and the intake manifold, under the throttle valve, the place of which is right on the segment with the cylinders.

How to check the knock sensor

Damage to the knock sensor First of all, error logs (codes) are displayed on the detection of the ecu by the on-board computer. Check Engine is displayed on the panel. This self-diagnosis system is necessarily found in modern Subaru models and is capable of fixing the sensitivity of the sensor, increasing the output voltage, and an open circuit. Each type of malfunction has its own code, the decryption is in the technical documentation on the machine, the information is available on the Internet.

Multimeter

You can analyze the health of the DD with a multimeter or voltmeter. Order:

- Dismantling the sensor: the fixing bolt is unscrewed, the assembly snaps off easily. The location, the appearance we used above, the sensor cannot be found.

- Tester probes are connected to the output. Multimeter conversion to DC current measurement, range is about 200mV (or less).

- With a reasonable effort, you need to start, you can press, use the dd part with a bolt, a metal rod, a screwdriver. By the time of use, the time will come and the birth of the house will occur from May 20 to May 30.

- Watch the devices. In good condition, the impact is accompanied by a power surge each time. Lack of response means failure.

The second verification method is similar to the one described, Only test translation in the resistance measurement mode (mark on the selector up to 1000 ohms or 1 kΩ). In the normal state will be about 400-600. At the moment of knocking, the value on the scoreboard will grow roughly (usually 1-2 com) and return to the original combination.

Recommendations:

- in all cases it is necessary to watch that the size on the display goes back. If this happens with an addiction, then the sensor is most likely broken;

- you need to make sure that the probes are securely connected - the contacts on the sensor may be dirty, p;

- voltage changes across the sensor can be several millivolts, not every test can display it. And when measuring resistance within Ohms, therefore, such a check is a priority;

- on a valid occasion, if you measure the voltage, the multimeter must have the required quality.

Checking the circuit to the computer block

The essence of the following. The sensor does not remove. Remove the ECU plug, first disconnect the "-" on the battery. Measure the magnitude of the applied pulses. The difficulty is that you need to know the pinout of the plug, which sockets of the pad turn off the sensor. To get acquainted with decent marriages manually or even easier - obtaining information from the

Described can be identified the possibility of an electrical circuit to the control unit, the value of the applied sensory impulse is measured. Order:

- Remove the block from the motor control unit.

- 2 contacts are found on the block, the tester probes are connected to them, if they do not turn on, you can solder the wires to them.

- The tester selector translates to a voltage mark of 200 mV.

- They knock on the sensor or do not listen to it in the presence. The numbers on the scoreboard should change in leaps and bounds.

It is also advisable to inspect the shielding braid from the ECU to the DD: due to its damage, harmonics may appear that affect the operation of the unit and the correct installation of the decision ECU.

Inspection without dismantling

It is possible to analyze the Subaru knock sensor, and it is not visible from the car:

- Switch the engine to idle.

- Tap on the working segment of the sensor.

- If the crankshaft speed is correct, the fact that if this does not happen, then a breakdown is not necessarily occurring

Difficulties in diagnosis

The disadvantage of independent methods for checking DD is that all of them do not allow to accurately, completely 100% even or as close as possible to determine the state of the sensor. The reason is in the peculiarities of functioning: for a normal operation device, pulses of frequency frequency, periodicity of oscillations must be created, and this depends on the level of vibrations, which is not so easy to create in all frequency changes.

Many of the above, full diagnostics with improvised means is impossible - only a check on a special stand or a diagnostic device gives an accurate result.

All independent methods with improvised tools, a multimeter, depending on the slight possibility of the sensor, but in some important cases, the jumps themselves are not displayed, but their additional characteristics, which are determined only by a specific tester.

Replacement

Preparatory stage - tools: fastening in the process of unscrewing with an open-end "10", a socket wrench "12", a ratchet with an extension, a crank. You will need a flathead screwdriver. For cleaning - rags, for rusty threads - penetrating lubricant.

Knock sensor replacement procedure

Removing the old and installing a new knock sensor on the Subaru Forester involves the following procedure. It is de-energized by the network, from the “-” terminal of the battery. They remove the intercooler, for which 2 fasteners are unscrewed, a pair of clamps is loosened.

Disconnect the "chip" (connector) of the knock sensor.

The fastening bolt is unscrewed, DD is pulled out with it.

The final stage is the installation of a new knock sensor. The assembly was carried out in the reverse order.