Knock sensor ZMZ 406

Content

Experienced drivers remember very well how a Zhiguli detonated when refueling with bad or low-octane gasoline. Engine knock occurs when the engine stops. For some time after turning off the ignition, it continues to rotate unevenly, “twitches”.

When driving on low-quality gasoline, as drivers say, it can “knock fingers”. This is also a manifestation of the detonation effect. In fact, this is far from a harmless effect. When exposed to it, significant overloads of pistons, valves, cylinder head and the engine as a whole occur. In modern cars, knock sensors (DD) are used in control systems to prevent engine knock).

What is detonation

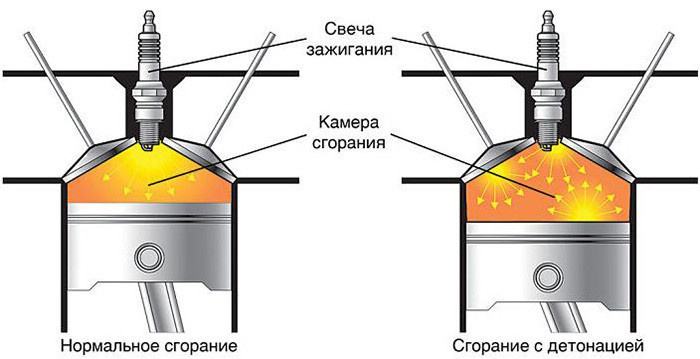

Engine knocking is the process of self-ignition of a mixture of gasoline and air without the participation of an ignition spark.

Theoretically, if the pressure in the cylinder exceeds the maximum allowable value for a mixture with gasoline of a certain octane number, self-ignition occurs. The lower the octane number of gasoline, the lower the compression ratio in this process.

When the engine is detonated, the self-ignition process is chaotic, there is no single source of ignition:

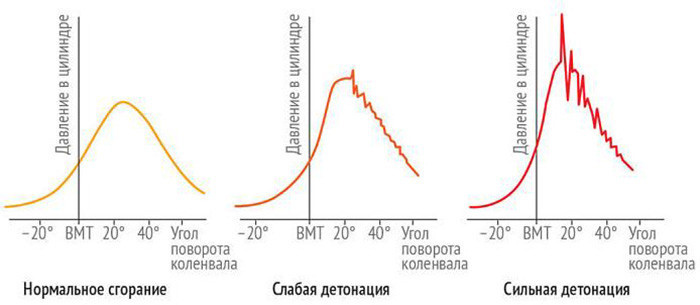

If we build the dependence of the pressure in the cylinder on the ignition angle, then it will look like this:

The graph shows that during detonation, the maximum pressure in the cylinder is almost twice the maximum pressure during normal combustion. Such loads can lead to engine failure, even as severe as a cracked block.

The main factors leading to the detonation effect:

- wrong octane number of the filled gasoline;

- design features of the internal combustion engine (compression ratio, piston shape, combustion chamber characteristics, etc.) contribute to an increase in the likelihood of this effect);

- characteristics of the operation of the power unit (ambient air temperature, gasoline quality, condition of candles, load, etc.).

appointment

The main purpose of the knock sensor is to detect the occurrence of this harmful effect in time and transmit information to the electronic engine control unit to adjust the quality of the gasoline-air mixture and the ignition angle in order to avoid dangerous engine knocks.

Registration of the fact of this impact is carried out by converting the mechanical vibrations of the engine into an electrical signal.

Principle of operation

The principle of operation of almost all knock sensors is based on the use of the piezoelectric effect. The piezoelectric effect is the ability of some materials to form a potential difference under mechanical stress.

Most men have used piezoelectric lighters and know they create a serious electrical spark. These high voltages do not occur at the knock sensors, but the signal received in this case is sufficient for the engine control unit.

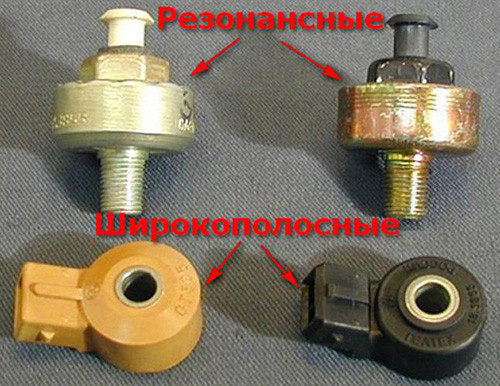

Two types of knock sensors are used: resonant and broadband.

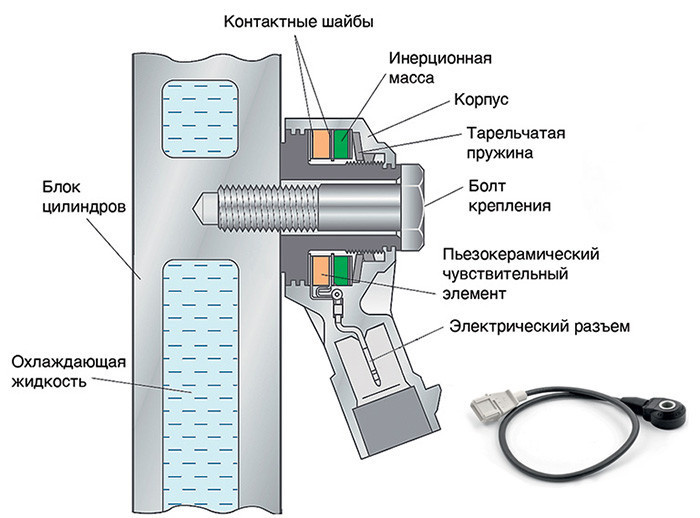

Broadband DD scheme used on VAZ and other foreign-made cars:

Broadband sensors are mounted on the cylinder block very close to the combustion zone. The support has a rigid character so as not to dampen shock impulses in the event of a malfunction of the internal combustion engine.

The piezoceramic sensing element generates an electrical impulse of sufficient amplitude for processing by the engine control unit in a wide frequency range.

Broadband sensors form a signal, both when the ignition is off with the engine stopped at low speeds, and at high speeds while driving.

Some vehicles, such as Toyota, use resonant sensors:

Such DDs operate at low engine speeds, at which, due to the resonance phenomenon, the greatest mechanical effect on the piezoelectric plate is achieved, respectively, a large signal is formed. It is no coincidence that a protective shunt resistor is installed on these sensors.

The advantage of resonant sensors is the filtering of mechanical effects when driving on rough roads, extraneous mechanical shocks that are not associated with engine detonation.

DD resonant type are installed on their own threaded connection, they resemble oil pressure sensors in shape.

Knock Sensor Malfunction Symptoms

The main symptom indicating a malfunction of the knock sensor is a direct manifestation of the engine malfunction effect described above.

In many cases, this can be the cause of mechanical destruction of the sensor, in particular, at the moment of impact during an accident, or moisture penetration into the connector or through a crack in the region of the piezoelectric sensor.

If the DD begins to break down mechanically, during the movement, the voltage value at its terminals can change dramatically. The engine control unit will respond to power surges such as possible detonation.

With spontaneous adjustment of the ignition angle, the engine starts, the speed floats. The same effect can occur if the sensor mounting is loose.

How to check the knock sensor

Computer diagnostics do not always fix a malfunction of the knock sensor. Engine diagnostics usually occur in stationary mode at the service station, and the knock is more pronounced when the car is moving with increased loads (in high gear) or at the moment the ignition is turned off, when computer diagnostics are basically impossible.

Without removing from the car

There is a method for diagnosing a knock sensor without removing it from its usual place. To do this, start and warm up the engine, then at idle hit a small metal object on the sensor mounting bolt. If there is a change in engine speed (change in speed), then DD works.

Multimeter

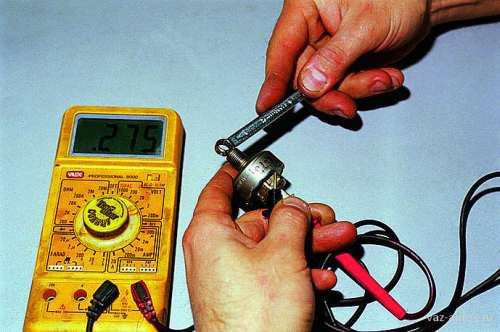

The most reliable way to check the performance is to disassemble the sensor, disconnect the connector, connect a multimeter to its terminals in the voltage measurement position of 2 volts.

Then you need to hit him with a metal object. The multimeter readings should increase from 0 to several tens of millivolts (it is better to check the pulse amplitude from the reference book). In any case, if the voltage rises when touched, the sensor is electrically unbreakable.

It is even better to connect an oscilloscope instead of a multimeter, then you can accurately determine even the shape of the output signal. This test is best done at a service station.

Replacement

In the event that there is a suspicion of a malfunction of the knock sensor, it should be changed. In general, they rarely fail and have a long resource, often exceeding the engine resource. In most cases, a malfunction is formed as a result of an accident or the dismantling of a power unit during a major overhaul.

The principle of operation of knock sensors is the same for each type (resonant and broadband). Therefore, sometimes you can use a device from other engine models if there is no native one. Of course, if it fits the landing data and connector. It is allowed to install a DD that was in operation from a disarmed one.

Tips

Some motorists forget about DD, since he rarely remembers his existence, and his problems do not cause such consequences as in the event of a malfunction, for example, of a crankshaft position sensor.

However, the result of a malfunction of this device can be much greater problems with the engine. Therefore, when operating the vehicle, make sure that the knock sensor:

- he was well protected;

- there were no oily fluids on his body;

- There were no signs of corrosion on the connector.

How to check DTOZH with a multimeter and what nuances it is better to know.

Video: where is the knock sensor ZAZ Lanos, Chance, Chery and how to check it with a multimeter, and also without removing it from the car:

May be of interest:

I'm afraid that after the accident, not everyone will remember this sensor, there will be many other problems. But I didn't know about the oiliness that can damage it, I need to see how it feels in my car. There are no signs of damage yet, the engine is running fine, but who knows. As for detonation in Zhiguli, it appeared on all old cars from time to time, something terrible, I tell you, if they didn’t drive old carburetor engines. The car is already bouncing and rumbles, you see, now something will fall off.

I also had trouble with this sensor. Dynamics is not the same, slightly increased consumption. Ultimately, when it turned out that things were wrong with this sensor, it would not be possible to simply change it either, because 1 out of 10 such sensors work at the VAZ. That is, you need to go shopping with a tester and check each new sensor

To be honest, I have never heard of this sensor failing on modern cars. In FF2 for 9 years they have never been dismantled. I know exactly what it is (there was a five in the late 90s). In general, drive with the specified gasoline and do not look for savings, it will be more expensive.

From my experience in operating a car, I know for sure that a car's knock sensor rarely fails. In my life I had to use, for a long period, such domestic cars as: Moskvich-2141, with a six-wheeled Zhiguli engine (about 7 years); Zhiguli -2107 (about 7 years old); Lada ten (about 6 years), in total for almost twenty years of experience in operating these cars, the pressure sensor has never failed. But detonation in the engines of these cars had to be observed more than once. Especially in the nineties, the quality of gasoline that was poured into cars at gas stations was terrible. The gasoline dispenser 92 was often filled with gasoline of the lowest octane number, poorly settled, with the presence of water or other liquids. After such refueling, the engine fingers began to knock, and when the load increased, it seemed that they wanted to jump out of a running car.

If gasoline was also with water, then the engine had to sneeze for a long time. Sometimes, as it seemed to drivers, in order to save on the purchase of gasoline, gasoline of a lower quality than prescribed by the car manufacturer was poured into the tank. At the same time, you turn off the car, turn off the ignition, and the engine continues to shake ugly, sometimes with characteristic pops in the muffler, as if you had the ignition set incorrectly, then the engine had to sneeze for a long time. Sometimes, as it seemed to drivers, in order to save on the purchase of gasoline, gasoline of a lower quality than prescribed by the car manufacturer was poured into the tank. At the same time, you turn off the car, turn off the ignition, and the engine continues to shake ugly, sometimes with characteristic pops in the muffler, as if you had the ignition set incorrectly, then the engine had to sneeze for a long time. Sometimes, as it seemed to drivers, in order to save on the purchase of gasoline, gasoline of a lower quality than prescribed by the car manufacturer was poured into the tank. At the same time, you turn off the car, turn off the ignition, and the engine continues to shake ugly, sometimes with characteristic pops in the muffler, as if you had the ignition set incorrectly.

Of course, with such symptoms, the engine was damaged.

I ran into a knock sensor when I couldn't get off a traffic light one day. The engine exploded in a terrible way. Somehow got into the service. They checked everything and even replaced the sensor, the effect is the same. And then I first came across a device that performs spectral analysis of fuel. That's when the guys showed me that instead of 95 I don't even have 92, but I like 80. So before you deal with the sensor, check the gas.

How many years have I been operating the car and driving since 1992? This is the first time I hear about this sensor, to my embarrassment. Raised under the hood, found, checked, as in its place. I have never had problems with the sensor.

Knock sensor check

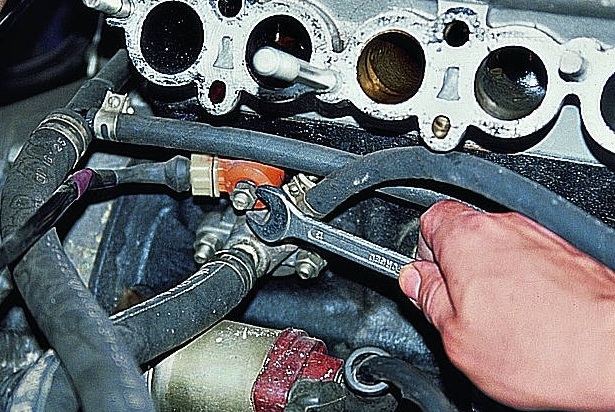

Switch off the ignition and remove the negative battery terminal.

Using the “13” key, we unscrew the nut that secures the sensor to the wall of the cylinder block (for clarity, the intake manifold is removed).

Prying off the spring clip on the block with a thin screwdriver, disconnect the wire block from the sensor.

We connect a voltmeter to the sensor terminals and, lightly tapping the sensor body with a solid object, we observe a change in voltage

The absence of voltage pulses indicates a malfunction of the sensor.

It is possible to fully check the sensor for malfunctions only on a special vibration support

Install the sensor in the reverse order.