Camshaft position sensor, its functions in the internal combustion engine

Content

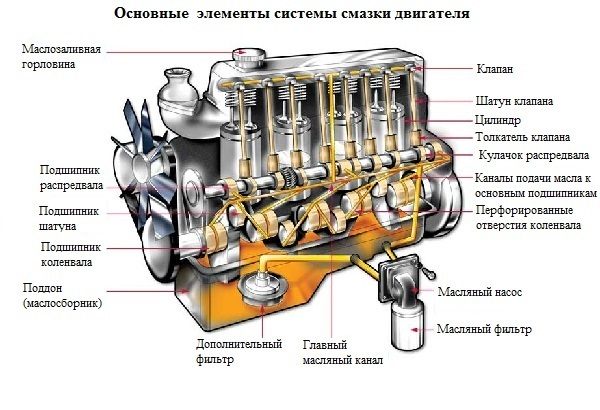

Modern engines have a rather complex design and are controlled by an electronic control unit (ECU) receiving information from sensors. Each sensor monitors certain parameters that characterize the operation of the engine at the current time, and transmits information to the ECU. In this article, we will look at one of the most important components of the engine management system - the camshaft position sensor (DPRS).

What is a camshaft position sensor

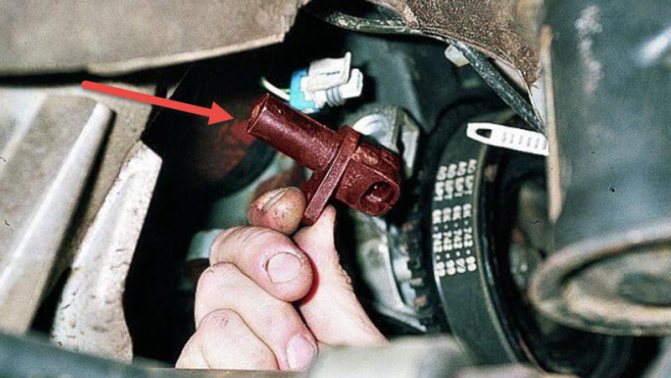

DPRV means camshaft position sensor. Other names: Hall sensor, phase sensor or CMP (English abbreviation). From the name it is clear that it is involved in the operation of the gas distribution mechanism. More precisely, the system calculates the ideal fuel injection and ignition timing based on its data.

This sensor uses a reference supply voltage - 5V, and its sensing element is a Hall sensor. It does not determine the moment of injection or ignition, but only provides information about when the piston reaches TDC in the first cylinder. Based on these data, the injection time and duration are calculated.

In its work, the DPRV is functionally connected to the crankshaft position sensor (DPKV), which is also responsible for the proper operation of the ignition system. If for some reason a malfunction of the camshaft sensor occurs, then the crankshaft sensor information will be taken into account. The signal from the DPKV is more important in the operation of the ignition and injection system; without it, the engine simply will not work.

DPRV is used in all modern engines, including internal combustion engines with variable valve timing. Depending on the design of the engine, it is installed in the cylinder head.

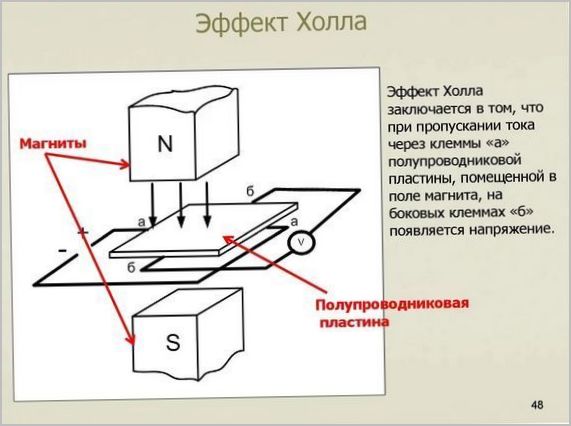

Hall effect and DPRV design

As already mentioned, the sensor works on the Hall effect. This effect was discovered in the 19th century by the scientist of the same name. He noticed that if a direct current flows through a thin plate and is placed in the field of action of a permanent magnet, then a potential difference is created at its other ends. This means that under the action of magnetic induction, some electrons are deflected and create a small voltage at the other edges of the plate (Hall voltage). It is used as a signal.

The DPRV is organized in the same way, but only in an improved form. It contains a permanent magnet and a semiconductor to which four pins are connected. The signal is fed to the input of the integrated circuit, where it is processed and then fed to the output contacts of the sensor, which are located on the sensor housing. The body itself is made of plastic.

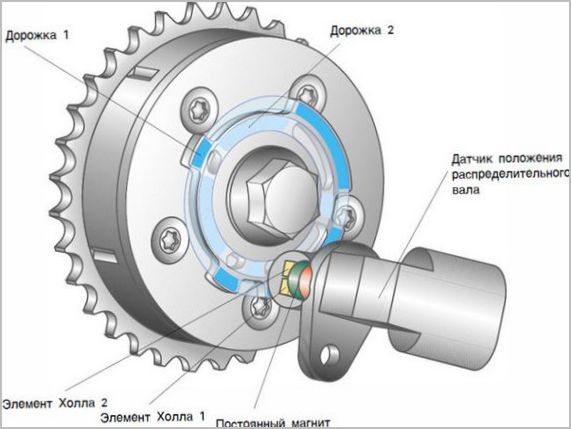

How the camshaft position sensor works

The driving disk (impulse wheel) is mounted on the camshaft from the side opposite to the DPRV. In turn, there are special teeth or protrusions on the camshaft drive disk. When these protrusions pass through the DPRV sensor, it generates a digital signal of a special form, which shows the current stroke in the cylinders.

It is necessary to get acquainted with the operation of the camshaft sensor more correctly in conjunction with the DPKV. Two revolutions of the crankshaft correspond to one revolution of the camshaft. This is the secret of synchronization of injection and ignition systems. In other words, DPRV and DPKV show the moment of the compression stroke in the first cylinder.

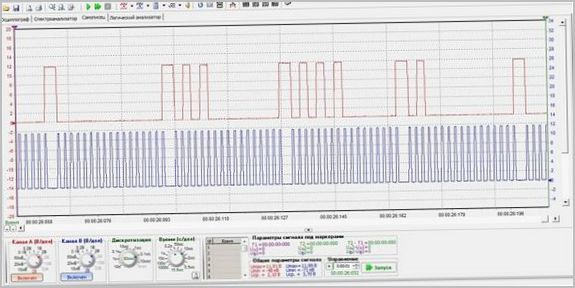

The crankshaft drive disc has 58 teeth, so when passing through the area where two teeth are missing through the crankshaft sensor, the system checks the signals from the DPRV and DPKV and determines the moment of injection into the first cylinder. After 30 teeth, injection occurs, for example, into the third cylinder, and then into the fourth and second. This is how synchronization works. All these signals are pulses and are read by the engine control unit. They can only be seen on an oscillogram.

Basic sensor malfunctions

It should be said right away that if the camshaft sensor fails, the engine will continue to run and start, but with a delay.

A malfunction of the DPRV may be indicated by the following symptoms:

- increased fuel consumption due to non-synchronization of the injection system;

- the car jerks and loses momentum;

- a noticeable loss of power, the car cannot accelerate;

- the engine does not start immediately, but with a delay of 2-3 seconds or stalls;

- the ignition system works with passes;

- the on-board computer gives an error, the Check Engine light is on.

These symptoms may indicate that the RPP is not working properly, but may also indicate other problems. It is necessary to carry out diagnostics in the service.

Reasons for the failure of the DPRV:

- contact and/or wiring failure;

- there may be a chip or bend on the protrusion of the disk with teeth, due to which the sensor reads incorrect data;

- damage to the sensor itself.

The sensor itself rarely fails.

Sensor diagnostic methods

Like any other hall effect sensor, the camshaft position sensor cannot be tested by measuring the voltage across the pins with a multimeter. A complete picture of its operation can only be obtained by checking it with an oscilloscope. The waveform will display pulses and dips. You also need to have some knowledge and experience to read waveform data. This can be done by a competent specialist at a service station or service center.

If a malfunction is detected, the sensor is replaced with a new one, repair is not provided.

DPRV plays an important role in the ignition and injection system. Its failure leads to problems in the operation of the engine. When symptoms are detected, it is better to diagnose by qualified specialists.