The composition and purpose of the lubrication system of an automobile engine

Content

The mechanical part of the car's motor, with the exception of mounted units, is usually devoid of rolling bearings. The principle of lubrication of sliding friction pairs is based on supplying them with liquid oil under pressure or operating under conditions of the so-called oil mist, when droplets suspended in crankcase gases are supplied to the surface.

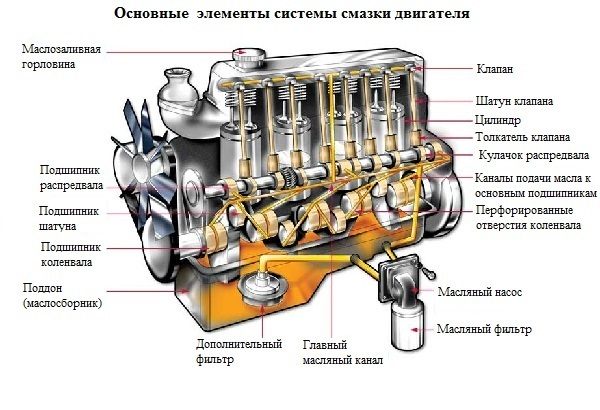

Lubrication system equipment

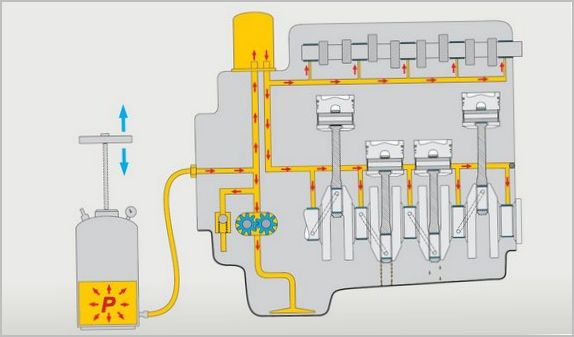

The oil reserve is stored in the engine crankcase, from where it must be lifted and delivered to all lubricated units. For this, the following mechanisms and details are used:

- oil pump driven by the crankshaft;

- chain, gear or direct oil pump drive;

- coarse and fine oil filters, recently their functions have been combined in a full-flow filter, and a metal mesh is installed at the inlet of the oil receiver to trap large particles;

- bypass and pressure reducing valves regulating pump pressure;

- channels and lines for supplying lubricant to friction pairs;

- additional calibrated holes that create oil mist in the required areas;

- crankcase cooling fins or separate oil cooler in heavily loaded engines.

A number of motors also use oil as a hydraulic fluid. It controls valve clearance hydraulic compensators, all kinds of tensioners and regulators. The performance of the pump increases proportionally.

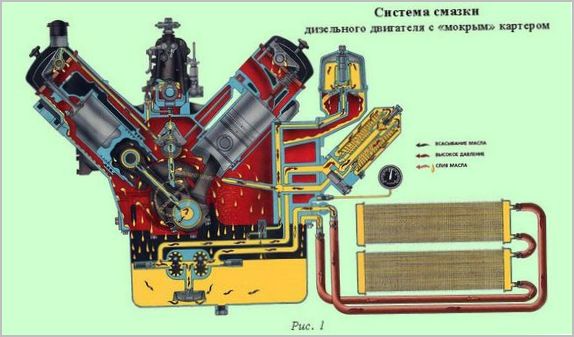

Varieties of systems

On an enlarged basis, all design solutions can be divided into systems with a dry sump and with an oil bath. For civilian vehicles, it is quite enough to use a drive in the form of an engine oil pan. The oil that has fulfilled its functions flows there, is partially cooled and then climbs through the oil receiver again into the pump.

But this system has a number of disadvantages. The car is not always clearly oriented relative to the gravitational vector, especially in dynamics. Oil can slosh on bumps, move away from the pump intake when the body tilts or overloads occur during acceleration, braking, or sharp turns. This leads to the exposure of the grid and the capture of crankcase gases by the pump, that is, the airing of the lines. Air has compressibility, so the pressure becomes unstable, there may be interruptions in supply, which is unacceptable. The plain bearings of all main shafts, and especially turbines in supercharged engines, will locally overheat and collapse.

The solution to the problem is to install a dry sump system. It is not dry in the literal sense of the word, just the oil that gets there is immediately picked up by pumps, of which there may be several, freed from gas inclusions, accumulated in a separate volume and then goes uninterruptedly to the bearings. Such a system is structurally more complicated, more expensive, but there is no other way out on sports or forced engines.

Ways to supply lubricant to the nodes

There is a difference between pressure feed and splash lubrication. Separately, they are not used, so we can talk about the combined method.

The main components that require high-quality lubrication are the crankshaft, camshaft and balancer shaft bearings, as well as the drive of additional equipment, in particular, the oil pump itself. The shafts rotate in beds formed by boring of the engine body elements, and to ensure minimal friction and maintainability, replaceable liners made of antifriction material are located between the shaft and the bed. Oil is pumped through the channels into the gaps of the calibrated section, which maintains the shafts in conditions of fluid friction.

The gaps between pistons and cylinders are lubricated by splashing, often through separate nozzles, but sometimes by drilling into connecting rods or simply by crankcase oil mist. In the latter cases, wear will be greater, scuffing is possible.

Special mention should be made of the lubrication of the turbine bearings. This is a very important node, because there the shaft rotates at great speed, floating up in the pumped oil. Here, heat is removed from a highly heated cartridge due to the intensive circulation of oil. The slightest delay leads to immediate breakdowns.

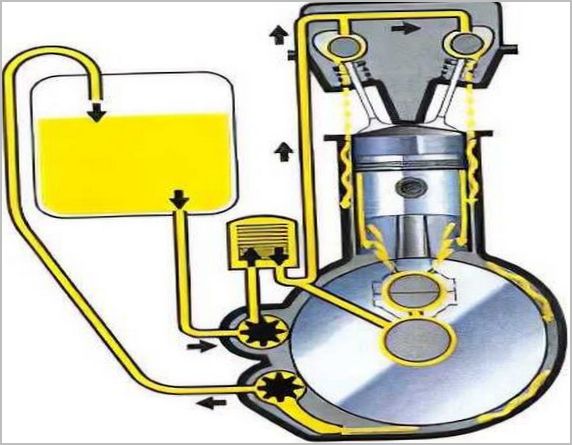

Engine oil turnover

The cycle begins with the intake of liquid from the crankcase or the collection of oil that enters there by the pumps of the "dry" type system. At the inlet of the oil receiver, there is a primary cleaning of large foreign objects that got there in different ways due to a violation of the repair technology, engine malfunctions or wear of the lubricating product itself. With an excess of such dirt, coarse mesh blockage and oil starvation at the pump inlet are possible.

The pressure is not controlled by the oil pump itself, so it may exceed the maximum allowable value. For example, due to deviations in viscosity. Therefore, a pressure reducing valve is placed parallel to its mechanism, dumping excess back into the crankcase in emergency situations.

Next, the liquid enters the full-flow fine filter, where the pores have a micron size. There is a thorough filtration so that particles that can cause scratches to rubbing surfaces do not get into the gaps. When the filter is overfilled, there is a danger of rupture of its filter curtain, so it is equipped with a bypass valve that directs the flow around the filter. This is an abnormal situation, but it partially relieves the engine of dirt accumulated in the filter.

Through numerous highways, the filtered flow is directed to all engine nodes. With the safety of the calculated gaps, the pressure drop is under control, their size provides the necessary throttling of the flow. The oil path ends with its reverse discharge into the crankcase, where it is partially cooled and again ready for operation. Sometimes it is passed through an oil cooler, where part of the heat is released into the atmosphere, or through a heat exchanger into the engine cooling system. This maintains the permissible viscosity, which strongly depends on temperature, and also reduces the rate of oxidative reactions.

Features of lubrication of diesel and heavily loaded engines

The main difference lies in the specified properties of the oil. There are a number of important product features:

- viscosity, especially its dependence on temperature;

- durability in maintaining properties, that is, durability;

- detergent and dispersant properties, the ability to separate pollution products and keep them out of the details;

- acidity and resistance to corrosion, especially as the oil ages;

- the presence of harmful substances, in particular sulfur;

- internal friction losses, energy-saving ability.

Diesels especially need resistance to fouling. Running heavy fuel oil with a high compression ratio contributes to the concentration of soot and sulfuric acid in the crankcase. The situation is aggravated by the presence of turbocharging in each passenger diesel engine. Hence the instructions for the use of special oils, where this is taken into account in the additive package. Plus more frequent replacement as wear accumulation is inevitable anyway.

The oil consists of a base base and an additive package. It is customary to judge the quality of a commercial product by its basis. It can be mineral or synthetic. With a mixed composition, the oil is called semi-synthetic, although usually it is a simple “mineral water” with a small addition of synthetic components. Another myth is the absolute advantage of synthetics. Although it also comes from different origins, most budget products are made from the same petroleum products by hydrocracking.

The importance of maintaining the right amount of oil in the system

For systems with an oil bath in the crankcase, the level must be maintained within fairly strict limits. The compactness of the engine and the requirements for the economical use of expensive products do not allow the creation of bulky pallets. And exceeding the level is fraught with touching the crankshaft cranks with an oil bath mirror, which will lead to foaming and loss of properties. If the level is too low, then lateral overloads or longitudinal accelerations will lead to the exposure of the oil receiver.

Modern engines are prone to oil consumption, which is associated with the use of shortened piston skirts, thin energy-saving rings and the presence of a turbocharger. Therefore, they especially need regular monitoring with an oil dipstick. Additionally, level sensors are installed.

Each engine has a set limit on oil consumption, measured in liters or kilograms per thousand kilometers. Exceeding this indicator means problems with wear of the cylinders, piston rings or oil seals of the valve stems. Noticeable smoke from the exhaust system begins, contamination of catalytic converters and the formation of soot in the combustion chambers. The motor needs to be overhauled or replaced. Oil burnout is one of the main indicators of the condition of the engine.