abs sensors for renault lagoon

Content

ABS, or the vehicle's anti-lock braking system, is used to prevent the wheels from locking during emergency braking. It includes an electronic control unit, a hydraulic unit, sensors for turning the front and rear wheels. The main task of the system is to maintain controllability of the vehicle, ensure stability and shorten the braking distance. Therefore, it is very important to maintain the good condition of all its elements. You can also check the ABS sensor yourself, for this you need to know what type of sensor is installed on the car, the signs indicating its failure, and how to check it. Let's consider everything in order.

Types of ABS sensors

Three types of ABS sensors are most common in modern cars:

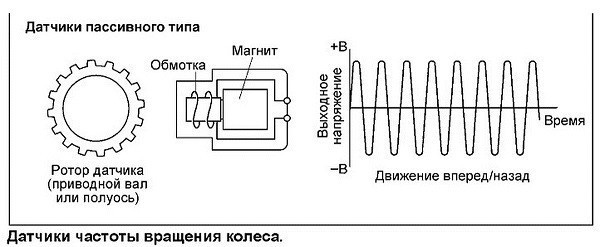

- passive type - its basis is an induction coil;

- magnetic resonance - acts on the basis of a change in the resistance of materials under the influence of a magnetic field;

- active - works on the principle of the Hall effect.

Passive sensors begin to work with the start of movement and read information from the toothed impulse ring. A metal tooth, passing through the device, causes the generation of a current pulse in it, which is transmitted to the computer. The sensors are triggered at a speed of 5 km/h. Pollution does not affect its performance.

Active sensors consist of electronic components and a permanent magnet located in the hub. When the magnet passes through the device, a potential difference is formed in it, which is formed in the control signal of the microcircuit. The electronic control unit then reads the data. These ABS sensors are extremely rare and cannot be repaired.

Passive type ABS sensors

Structurally simple and reliable device with a long service life. Does not require additional power. It consists of an induction coil, inside which is placed a magnet with a metal core.

When the car moves, the metal teeth of the rotor pass through the magnetic field of the core, changing it and forming an alternating current in the winding. The higher the transport speed, the greater the frequency and amplitude of the current. Based on the received data, the ECU gives commands to the solenoid valves. The advantages of this type of sensors include low cost and ease of replacement.

Disadvantages of a passive ABS sensor:

- relatively large size;

- low data accuracy;

- not included in the work at speeds up to 5 km / h;

- works at the minimum speed of the steering wheel.

Due to constant failures, it is rarely installed on modern cars.

ABS magnetic resonance sensor

Its work is based on the ability to change the electrical resistance of a ferromagnetic material under the influence of a constant magnetic field. The section of the sensor responsible for monitoring changes is made of two to four layers of iron and nickel plates with conductors placed on them. The other part is installed on the integrated circuit and reads the changes in resistance, forming a control signal.

The rotor of this design is made of a plastic ring with magnetic sections and is rigidly fixed to the wheel hub. When the machine moves, the magnetic sections of the rotor act on the magnetic field of the plates of sensitive elements, which is recorded by the circuit. A pulse signal is generated and transmitted to the control unit.

The ABS magnetic resonance sensor detects changes in wheel rotation with high accuracy, which improves driving safety.

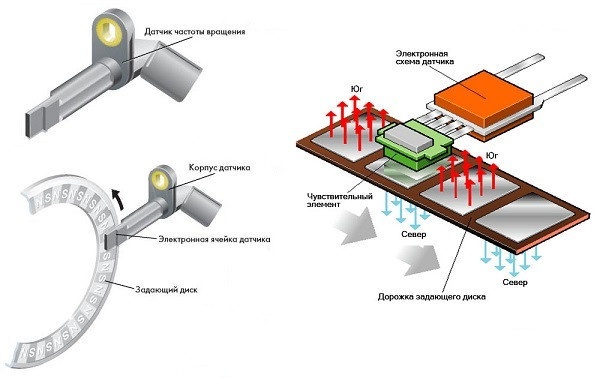

Based on the Hall effect

His work is based on the Hall effect. At different ends of a flat conductor placed in a magnetic field, a transverse potential difference is formed.

In sensors, this conductor is a square metal plate placed on a microcircuit, which includes a Hall integrated circuit and a control electronic circuit. The ABS sensor is located in front of the supercharged rotor. The rotor can be all-metal with teeth or in the form of a plastic ring with magnetic sections and is rigidly fixed to the wheel hub.

In such a circuit, signal bursts are constantly formed at a certain frequency. In a calm state, the frequency is minimal. When metal teeth or magnetic areas move, they pass through the magnetic field and cause a change in current in the sensor, which is tracked and registered by the circuit. Based on these data, a signal is generated and transmitted to the ECU.

The sensors are triggered immediately after the start of movement, they are highly accurate and ensure reliable operation of the systems.

Signs and causes of ABS sensor malfunctions

One of the first signs of a malfunction of the ABS system is the glow of the indicator on the dashboard for more than 6 seconds after the ignition is turned on. Or lights up after the start of the movement.

There can be many reasons for the defect, we indicate the most common:

- Breakage of sensor wires or malfunction of the controller unit. In such cases, an error appears on the dashboard, the system turns off, and the signal for a change in angular velocity is not given.

- The wheel sensor has failed. After turning on, the system starts self-diagnostics and finds an error, but continues to work. It is possible that oxidation appeared on the sensor contacts, which caused a bad signal, or the ABS sensor shorted or “fell” to the ground.

- Mechanical damage to one or more elements: hub bearing, rotor backlash in the sensor, etc. In such cases, the system will not turn on.

The most vulnerable link in the entire system is the wheel sensor located near the rotating hub and axle shaft. The appearance of dirt or play in the hub bearing can cause a complete blockage of the ABS system. The following symptoms indicate a sensor malfunction:

- an ABS error code appears in the on-board computer;

- lack of characteristic vibration and sound when pressing the brake pedal;

- during emergency braking, the wheels are blocked;

- the parking brake signal appears in the off position.

If one or more signs are found, the first step is to diagnose the wheel sensor.

How to Diagnose the ABS System

To obtain complete and reliable information about the state of the entire system, it is necessary to carry out diagnostics using special equipment. For this, the manufacturer provides a special connector. After connecting, the ignition is turned on, from which the test begins. The adapter generates error codes, each of which indicates the failure of a particular node or element of the system.

A good model of such a device is the Scan Tool Pro Black Edition from Korean manufacturers. A 32-bit chip allows you to diagnose not only the engine, but also all components and assemblies of the car. The cost of such a device is relatively low.

In addition, diagnostics can be carried out at service centers and service stations. However, even in garage conditions, with some knowledge, it will not be difficult to identify defects. To do this, you will need the following set of tools: a soldering iron, a tester, heat shrink and repair connectors.

The check is performed in the following sequence:

- overhauled wheel raised;

- the control unit and controller outputs are dismantled;

- repair connectors are connected to the sensors;

- resistance is measured with a multimeter.

A fully functional ABS sensor at rest has a resistance of 1 kΩ. When the wheel is rotated, the readings should change, if this does not happen, the sensor is faulty. It must be remembered that different sensors have different meanings, so before starting work, you need to study them.

Checking the ABS sensor with a multimeter

In addition to the device itself, you should find a description of the sensor model. Further work is carried out in the following sequence:

- The machine is placed on a flat, even surface, after which its position is fixed.

- The wheel is removed, where the ABS sensor will be checked.

- The connector is disconnected and the contacts of both the sensor and the plug itself are cleaned.

- Cables and their connections are inspected for abrasions and other signs of damage to the insulation.

- The multimeter switch enters resistance measurement mode.

- The probes of the tester are applied to the output contacts of the sensor and the readings are taken. Under normal conditions, the display of the device should show the number indicated in the sensor passport. If there is no such information, we take readings of 0,5 - 2 kOhm as the norm.

- Then, without removing the probes, the wheel of the car is spinning. If the sensor is working, the resistance will change and the higher the rotation speed, the more the resistance will change.

- The multimeter switches to voltage measurement mode and the measurement is taken.

- At a wheel rotation speed of 1 rpm. The indicator should be in the range of 0,25 - 0,5 V. The higher the rotation speed, the higher the voltage.

- All sensors are checked in the same sequence.

In addition, the entire wiring harness is called between each other to make sure there is no short circuit.

It should be remembered that the design and meanings of the front and rear axle sensors are different.

Based on the data obtained during the measurements, the operability of the sensor is determined:

- the indicator is below the norm: the sensor cannot be used;

- very small or almost zero resistance indicator - the coil circuit rotates;

- when the bundle is bent, the resistance indicator changes - the wire strands are damaged;

- the resistance indicator goes to infinity: a break in the conductor or core in the induction coil.

You need to know if, during diagnostics, the resistance readings of one of the ABS sensors differ greatly from the rest, then it is faulty.

Before you start rattling the wires in the harness, you need to find out the pinout of the control module plug. Then the connections of the sensors and the ECU are opened. And after that, you can begin to sequentially ring the wires in the bundle according to the pinout.

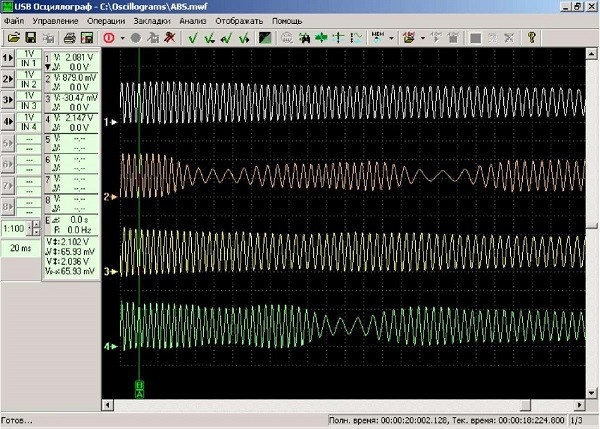

Checking the ABS sensor with an oscilloscope

An oscilloscope can also be used to determine the status of the ABS sensors. However, it is worth noting that this will require some experience with it. If you are an avid radio amateur, this will not seem difficult, but a simple layman may have a number of difficulties. And the main one is the cost of the device.

Such a device is more suitable for specialists and masters of service centers and service stations. However, if you have such a device, it will be a good helper and will help to identify malfunctions not only in the ABS system.

An oscilloscope displays an electrical signal. The amplitude and frequency of the current are displayed on a special screen, so you can get accurate information about the operation of a particular element.

So the test starts in the same way as with a multimeter. Only at the connection point of the multimeter, an oscilloscope is connected. And so the sequence is:

- the suspension wheel rotates at a frequency of approximately 2 - 3 revolutions per second;

- vibration readings are recorded on the dashboard.

After determining the integrity of the wheel, you should immediately start checking from the opposite side of the axle. Then the obtained data are compared and based on them conclusions are drawn:

- as long as the readings are relatively uniform, the sensors are in good condition;

- the absence of a step phenomenon when a smaller sine signal is set indicates the normal operation of the sensor;

- a stable amplitude with peak values not exceeding 0,5 V at the speeds mentioned above indicates that the sensor is in good condition.

Check without instruments

The performance of the ABS sensors can also be checked by the presence of a magnetic field. To do this, any iron object is taken and applied to the sensor body. It should pull when the ignition is on.

You should also carefully inspect the sensor itself and the place of its installation for damage. The cable must not be frayed, split, broken, etc. The sensor connector must not be oxidized.

It is important to know that the presence of dirt and oxidation can distort the sensor signal.

Hack and predictor Aviator

To diagnose the sensors of the ABS system, it is not necessary to go to a car repair shop, this can be done independently with the necessary tools. However, to get the full picture, you will need the right set of knowledge and some free time.

Methods for checking the ABS sensor

ABS sensors play an important role in the operation of the vehicle's braking system - the braking efficiency and the smooth operation of the unit as a whole depend on them. Sensor elements transmit data on the degree of rotation of the wheels to the control unit, and the control unit analyzes the incoming information, building the desired algorithm of actions. But what to do if there are doubts about the health of the devices?

Signs of device malfunction

The fact that the ABS sensor is faulty is signaled by an indicator on the instrument panel: it lights up when the system is turned off, goes out even with the slightest malfunction.

Evidence that the ABS has stopped "interfering" with the brakes:

- The wheels constantly lock up under heavy braking.

- There is no characteristic knocking with simultaneous vibration when pressing the brake pedal.

- The speedometer needle lags behind acceleration or does not move at all from its original position.

- If two (or more) sensors on the instrument panel fail, the parking brake indicator lights up and does not go out.

The ABS indicator on the dashboard indicates a system malfunction

What should I do if the ABS indicator on the dashboard of the car does not behave quite correctly? You should not immediately change the sensor, you first need to check the devices; this procedure can be performed independently, without resorting to the services of highly paid masters.

Health check methods

To determine the state of the part, we perform a series of actions to diagnose it, going from simple to complex:

- Let's check the fuses by opening the block (inside the passenger compartment or in the engine compartment) and inspecting the corresponding elements (indicated in the repair / operation manual). If a burnt component is found, we will replace it with a new one.

- Let's take a look and check:

- connector integrity;

- wiring for abrasions that increase the risk of a short circuit;

- contamination of parts, possible external mechanical damage;

- fixing and connecting to the ground of the sensor itself.

If the above measures do not help identify a device malfunction, it will have to be checked with devices - a tester (multimeter) or an oscilloscope.

Tester (multimeter)

For this method of diagnosing the sensor, you will need a tester (multimeter), instructions for operating and repairing the car, as well as PIN - wiring with special connectors.

The device combines the functions of an ohmmeter, ammeter and voltmeter

Tester (multimeter) - a device for measuring the parameters of electric current, combining the functions of a voltmeter, ammeter and ohmmeter. There are analog and digital models of devices.

To obtain complete information about the performance of the ABS sensor, it is necessary to measure the resistance in the device circuit:

- Raise the vehicle with a jack or hang it on a lift.

- Remove the wheel if it obstructs access to the device.

- Remove the system control box cover and disconnect the connectors from the controller.

- We connect the PIN to the multimeter and the sensor contact (the rear wheel sensor connectors are located inside the passenger compartment, under the seats).

We connect the PIN to the tester and the sensor contact

The readings of the device must correspond to the data specified in the manual for the repair and operation of a particular vehicle. If the resistance of the device:

- below the minimum threshold - the sensor is faulty;

- approaches zero - short circuit;

- unstable (jumping) at the moment of tightening the wires - a violation of the contact inside the wiring;

- endless or no readings - cable break.

Attention! The resistance of the ABS sensors on the front and rear axles is different. The operating parameters of the devices are from 1 to 1,3 kOhm in the first case and from 1,8 to 2,3 kOhm in the second.

How to check with an oscilloscope (with wiring diagram)

In addition to self-diagnosis of the sensor with a tester (multimeter), it can be checked with a more complex device - an oscilloscope.

The device examines the amplitude and time parameters of the sensor signal

An oscilloscope is a device that studies the amplitude and time parameters of a signal, which is designed to accurately diagnose pulse processes in electronic circuits. This device detects bad connectors, ground faults and wire breaks. The check is carried out by visual observation of the vibrations on the screen of the device.

To diagnose the ABS sensor with an oscilloscope, you must:

- Fully charge the battery in order to observe the voltage drop (spikes) on the connectors or leads during the measurement.

- Locate the touch sensor and disconnect the top connector from the part.

- Connect the oscilloscope to a power outlet.

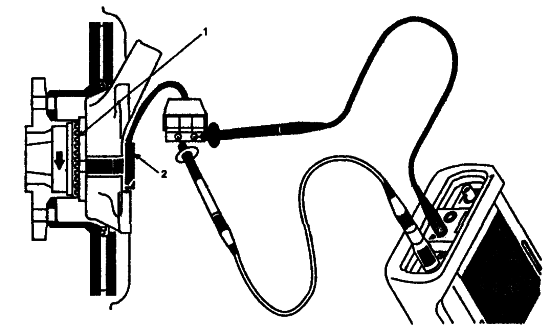

Connecting the device to the ABS sensor connector (1 - gear rotor; 2 - sensor)

The status of the ABS sensor is indicated by:

- the same amplitude of the signal fluctuation during the rotation of the wheels of one axle;

- the absence of amplitude beats when diagnosing with a sinusoidal signal of a lower frequency;

- maintaining a stable and uniform amplitude of signal oscillations, not exceeding 0,5 V, when the wheel rotates at a frequency of 2 rpm.

Please note that the oscilloscope is a rather complicated and expensive device. Modern computer technology makes it possible to replace this device with a special program downloaded from the Internet and installed on a regular laptop.

Checking a part without instruments

The easiest way to diagnose a hardwareless device is to check the solenoid valve on the induction sensor. Any metal product (screwdriver, wrench) is applied to the part in which the magnet is installed. If the sensor does not attract it, it is defective.

Most modern automotive anti-lock braking systems have a self-diagnosis function with error output (in alphanumeric coding) on the on-board computer screen. You can decipher these symbols using the Internet or the machine's instruction manual.

What to do if a breakdown is detected

What to do with the ABS sensor if a malfunction is detected? If the problem is the device itself, it will have to be replaced, but in the case of electrical wiring, you can fix the problem yourself. To restore its integrity, we use the “welding” method, carefully wrapping the joints with electrical tape.

If the ABS light comes on on the dashboard, this is a clear sign of a sensor problem. The described actions will help to identify the cause of the breakdown; however, if knowledge and experience are not enough, it is better to contact the car service masters. Otherwise, illiterate diagnostics of the condition, coupled with improper repair of the device, will reduce the effectiveness of the anti-lock braking system and may lead to an accident.