Torque wrenches "Zubr": instructions for use, real reviews and opportunities

Content

The Zubr trademark is a Russian brand that has been operating in the market of electronic and manual assembly tools since 2005. Tools are made in Taiwan (China). The brand's products demonstrate decent quality and durability. Torque wrenches of the company are among the top three leaders of domestic devices.

The fasteners of some vehicle units must be tightened with a certain force. For example, cylinder head bolts should be tightened evenly so that distortion does not occur, causing rapid wear of the gaskets.

Torque wrench "Zubr" - a tool made of durable steel. It can be adjusted to a specific clamping level, measured in Newton meters.

Possibilities of the torque wrench "Zubr"

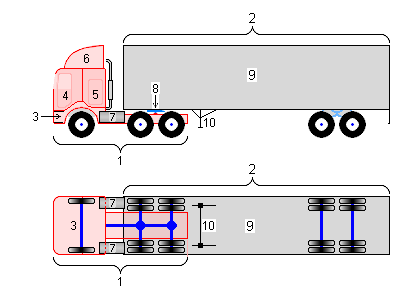

The Zubr torque wrench is a tool for high-precision tightening of threaded connections. The device is used to repair cars in auto repair shops, large car services, garage conditions. The tool handle is a rotary mechanism with scale divisions and Newton meters for setting the clamping force of threaded fasteners. The key is crowned with a head with a connecting square for nozzles for fasteners of various diameters.

Bison torque wrench

Trademark "Zubr" - one of the leaders in the market of such products, produces click-type torque wrenches with the same name. The company manufactures several types of such instruments.

Torque wrench "Zubr 64091 expert"

Torque wrench with low tightening force - 5-25 Nm. The diameter of the connecting square is 1/4 inch. The purpose of the tool is to adjust and adjust. In particular, this wrench is used to adjust diesel injectors and other small-sized fasteners or repair work in hard-to-reach places.

Bison 64091 expert

The special knurled handle of the wrench does not slip even in oil-smeared or wet hands. Tool Benefits:

- production material - tool steel of the highest grade, which determines the durability of the tool;

- high key accuracy - +/-4%;

- the ratchet mechanism of the device, made of chrome-molybdenum steel, is resistant to intense loads;

- strong locking mechanism.

Torque wrench "Bison 64093"

Made from high strength steel.

Bison 64093

Tool Benefits:

- comfortable non-slip handle with notches;

- high measurement accuracy (+/- 4%);

- durable ratchet mechanism made of molybdenum-chrome steel.

Tool force range - 19-110 Nm. Such values are quite enough to evenly and accurately tighten large fasteners on the nodes and assemblies of cars. For example, a force of 100 Nm is enough to tighten the wheel screws.

"Expert 64094"

The bolt tightening force range is from 42 to 210 Nm. This is the most common car repair key. The tool covers almost all needs for high-precision mounting assembly of vehicle units and assemblies.

Expert 64094

The device has the following features:

- maximum force range - 210 Nm;

- the size of the connecting square - ½;

- twisting mechanism - gear ratchet;

- production material - tool steel.

In terms of merits, this key is not inferior to previous samples. The tool is reliable. The convenient corrugated metal handle does not slip even from wet or oily hands.

How to use a torque wrench

Tightening fasteners with a snap-type torque wrench is fairly easy. The main thing is to know how to correctly set the tightening force range. To set the tool to the desired values and get to work, it is important to do everything in sequence. For example, let's imagine that you need to tighten a nut with a force of 100 Nm.

How to use a torque wrench

Work order:

- Loosen the lock nut at the bottom of the handle.

- Turn the lower part of the key handle, moving it up along the fixed scale of the tool.

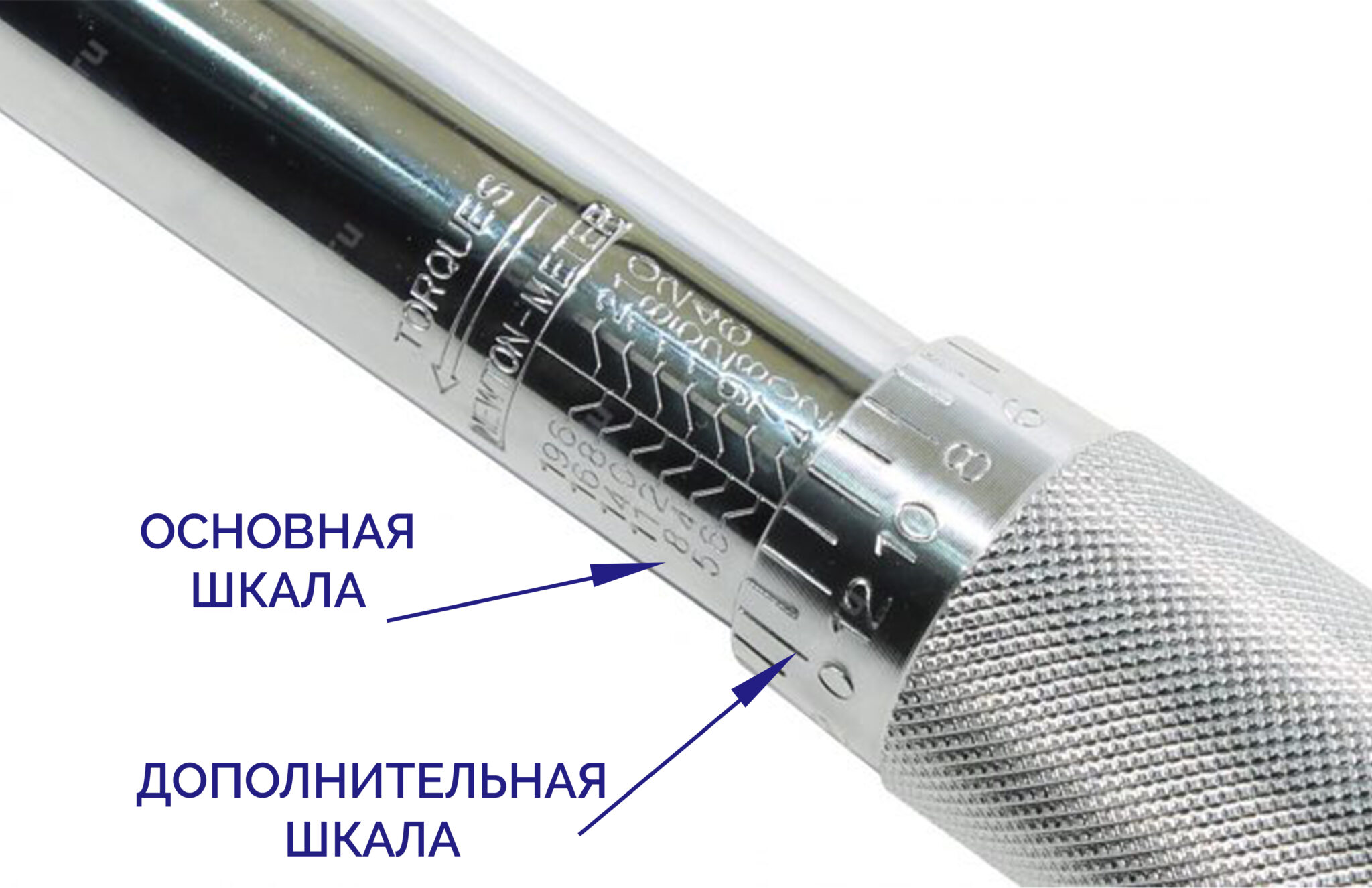

- Rotate the movable part of the handle so that the 0 mark on the lower scale coincides with the 98 Nm mark on the main scale.

- Set the tightening force to 100 Nm on the handle by screwing it up to mark 2 on the lower scale. Thus, the total sum will be 98+2=100. This will be the level of the set tightening force per 100 newton meters.

- Place an end head corresponding to the diameter of the fastener on the connecting square and begin to tighten the fastening screw.

When tightening, when the tightening force reaches the set limit, the key reacts with a characteristic sound click and will give into the hand. Such signals will notify that the bolt is twisted to a predetermined level.

If you continue to twist after a click, the key will work like a normal knob. In other words, it will further tighten the fasteners. It is not recommended to do this, as such rotation will create an additional load on the wrench mechanism and socket, which can lead to breakage of the bit or the tool itself.

Manufacturer

The Zubr trademark is a Russian brand that has been operating in the market of electronic and manual assembly tools since 2005. Tools are made in Taiwan (China). The brand's products demonstrate decent quality and durability. Torque wrenches of the company are among the top three leaders of domestic devices.

Reviews

Reviews about the Zubr torque wrench among professional car mechanics and ordinary car owners are mostly positive. Users note the ergonomics of the handle, high accuracy when tightening bolts and candles.

Among the minuses are the lack of legibility of digital values on the scale of the instrument, the lower quality of the device than that of expensive German or French devices.