Diesel. 5 Signs of an Expensive Repair

Content

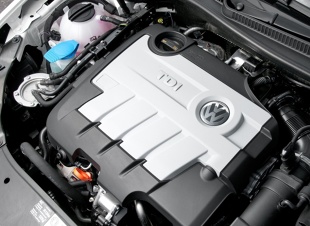

Analysts and market specialists, as well as car manufacturers themselves, foretell the imminent end of the era of diesel engines. Despite this, their popularity is still huge, and many drivers do not imagine driving a car with a different powertrain. Flexibility, high torque and low fuel consumption are the main advantages of diesel engines. Minus - expensive breakdowns, which, fortunately, can be diagnosed in time and quickly eliminated.

Analysts and market specialists, as well as car manufacturers themselves, foretell the imminent end of the era of diesel engines. Despite this, their popularity is still huge, and many drivers do not imagine driving a car with a different powertrain. Flexibility, high torque and low fuel consumption are the main advantages of diesel engines. Minus - expensive breakdowns, which, fortunately, can be diagnosed in time and quickly eliminated.

Modern diesel units are characterized by high parameters, efficiency and economy. High torque is available over a wide rev range and is almost instantaneous, typically around 1500 rpm. Such properties have a great influence on dynamics, performance, but most of all on maneuverability and low fuel consumption, especially on the road. In the city, these advantages are somewhat leveled and erased, but if you drive a lot and cover long distances, then appreciate the advantages of diesels.

Unfortunately, the complexity of modern diesel engines is so high that the risk of costly failure, especially in the case of careless handling and inadequate operation, increases extremely rapidly. Pretty much anything can fail and if we have a proven diesel design the risk is low and depends mostly on the driver and how they take care of the car.

However, hardware can be fickle, and even slight neglect or ignorance is enough to cause initial symptoms to quickly lead to costly failure. What is most likely to fail and cause the most cost?

Exhaust gas cleaning systems: DPF, SCR filters

Diesel particulate filters and other aftertreatment systems are a real nuisance for many diesel car users. While constant use on routes usually results in trouble-free use, frequent short distances in the city can quickly become quite problematic. I'm talking mainly about modern diesel vehicles, which, due to strict exhaust emission regulations, must have DPF filters and - mainly in the latest models - SCR systems that reduce nitrogen oxides (NOx).

Diesel particulate filters and other aftertreatment systems are a real nuisance for many diesel car users. While constant use on routes usually results in trouble-free use, frequent short distances in the city can quickly become quite problematic. I'm talking mainly about modern diesel vehicles, which, due to strict exhaust emission regulations, must have DPF filters and - mainly in the latest models - SCR systems that reduce nitrogen oxides (NOx).

With the age of the car and the number of kilometers traveled, the particulate filter wears out, or rather clogs with ash. A clogged filter must clean itself, and over time the intervals between cleaning cycles become shorter. As the filter burns out, the car becomes sluggish, the accelerator pedal response is delayed, combustion increases significantly, and in many cases, puffs of smoke come out of the exhaust pipe. While filter burn-in occurs on the road, it will sometimes be difficult to feel it, but if the computer turns on the process while driving around the city, it can cause a lot of problems. Then you should not turn off the engine, and the best solution is to drive along the highway at a slightly higher speed. However, this is not always possible - sometimes the driver stops the process unknowingly. If the regeneration cycle is constantly interrupted, the filter may become completely clogged and the engine will go into emergency mode. Solution?

If off-road driving does not help or the car refuses to obey at all, the solution may be the so-called forced service burn-out of the filter, which will cost several hundred zlotys. By the way, it is recommended to change the oil. By the way, such a process not only harms the engine, but also does not always fulfill its task, especially in the case of very old, damaged filters. Then the only solution is to replace the filter with a new one. In the case of the simplest ones, it costs about PLN 1500. More complex, installed on modern cars, can cost up to PLN 10. In addition, wet filters (usually manufactured by PSA) use a special fluid that costs more than PLN 000 per litre. The cost of AdBlue for SCR systems is much lower - usually less than PLN 100 per litre.

Turbocharger and its accessories

Another element that is very sensitive to mishandling. If the driver, after some time after starting the engine, regularly drives hard, does not wait for the engine to warm up, drives at too low a speed, and immediately after stopping after a dynamic ride, turns off the car, sooner or later this will lead to a breakdown of the turbo. Of course, there may be more reasons, such as a design defect, incorrect setting, or normal wear and tear. Turbocharger equipment may also fail. I'm talking about pressure sensors, intake or so-called. pear.

However, if the turbocharger is periodically inspected and the driver monitors the serviceability, there should be no serious problems. It is also important to notice a possible defect in time, so that it will be possible to react quickly, for example, by regeneration or replacement, before a serious breakdown occurs, for example, rotor elements getting inside the engine. In extreme cases, the drive can be completely destroyed. If the car does not have enough power, blue smoke comes out of the exhaust pipe, the engine oil level drops regularly, there is a lot of oil in the intercooler, and a distinct whistle or metallic sound is heard during acceleration, it is high time to check the condition of the turbocharger. Restoration of this element in a professional workshop costs about PLN 1000 (depending on the model). Buying a new turbine will cost several thousand zlotys.

Injection system

This is another element that fails not only due to old age, but also as a result of ignorance and negligence of the user. Injector tips damaged: by low-quality fuel, inept adjustment in the workshop or the use of aggressive programs aimed at increasing the serial engine power, i.e. chip tuning. In many engines, the nozzle tips are completely clogged with metal filings, which come, for example, from a damaged high-pressure fuel pump. It happens that the ignition coils burn out, there are problems with the control valves, as well as fuel leaks from under the seals (the so-called o-rings).

This is another element that fails not only due to old age, but also as a result of ignorance and negligence of the user. Injector tips damaged: by low-quality fuel, inept adjustment in the workshop or the use of aggressive programs aimed at increasing the serial engine power, i.e. chip tuning. In many engines, the nozzle tips are completely clogged with metal filings, which come, for example, from a damaged high-pressure fuel pump. It happens that the ignition coils burn out, there are problems with the control valves, as well as fuel leaks from under the seals (the so-called o-rings).

The first symptoms of damaged injectors are clearly difficult to start the engine, noticeable vibrations, black smoke from the exhaust and increased combustion. Proper diagnosis is rather complicated and unreliable, since even measuring injector corrections can be misleading. The best solution would be to diagnose overflow using a special device. Repair cost? Very varied.

Repair, or rather regeneration of older models operating under lower pressure, costs from 200 to 500 PLN. Only qualified service providers can deal with newer solutions, especially piezo injectors, and usually charge very large amounts. You should not give nozzles to inexperienced workshops that will do it clumsily and collect a large amount.

Vortex and EGR flaps

Another decision that should have a positive impact on the environment. Special dampers regulate the length of the intake system and swirl the air sucked into the cylinders. This, in turn, means that when driving without load, for example, downhill or at a constant speed, less toxic substances are emitted into the atmosphere. While everything is in order and relatively new, the system works flawlessly. Unfortunately, over the years and even hundreds of kilometers, the system begins to falter. Its work is negatively affected mainly by soot, which accumulates in the intake system and can block the mechanism. This, in turn, causes the check engine light to come on and the emergency mode to activate. Moreover, in the case of some engines, for example 1.9 16V (Fiat / Opel / Saab), the damper can come off and get into the engine, i.e. cylinders. This results in a very serious and usually permanent failure of the device.

There are many symptoms and they definitely do not indicate the failure of the vortex dampers. In most cases, there are problems with starting and lack of power during acceleration. Of course, in the event of jammed flaps, an engine light appears. Sometimes there are incorrect injector adjustments and increased smoke from the exhaust system. Expenses? There is also no single price list here, because cleaning the collector from soot costs several hundred zlotys. If a replacement is needed, it will cost more than PLN 1000. If an engine sucks on one of the dampers, it can cost several thousand to regenerate, depending on the severity of the damage. However, in many cases, replacement of the drive assembly is required.

See also: How to save fuel?

EGR, which is responsible for exhaust gas recirculation and regulates what the engine breathes, also causes a lot of problems. Simply put, the EGR valve opens or closes the flow between the exhaust and intake manifolds. If the driver does not need full power, he slows down by braking the engine, or drives at a constant speed, some of the exhaust gases are directed back into the intake manifold, which causes, among other things, a reduction in nitrogen oxide emissions. Unfortunately, like the swirl flaps, the EGR valve also works under severe conditions and often fails, mainly due to soot.

Symptoms include starting problems, power loss, smoke, and check engine light. Fortunately, the problem is quite easy to detect, and if we notice it in time, we will fix it without much effort. New vehicles use EGR valves with an aftercooler. If we do not notice the defect in time, it will leak, which in turn can lead to further problems. In the event of a malfunction, it makes sense to try normal cleaning first. A new EGR valve costs between PLN 250 and PLN 1000, the latest complex designs can cost up to PLN 2000.

Two-mass flywheel

Many legends have already arisen around the "two masses". Some say that a dual-mass flywheel can be used "for life", others that it rains very quickly or is not needed at all and can be converted to a conventional flywheel. True, about half way. This is an element that wears out, but if the car is properly maintained and the driver knows how to use the car with this solution, he should have no problems for tens of thousands of kilometers. And what "kills" a dual-mass flywheel? Driving at a very low speed, which generates a strong vibration of the power unit. In this case, the dual-mass wheel works at its limit, reducing vibrations. Fast acceleration from low revs is also very unprofitable - a diesel engine produces high torque even at low revs. This harshness of the gas and inexperienced handling of the clutch leads to the fact that the dual-mass flywheel quickly makes itself felt.

Many legends have already arisen around the "two masses". Some say that a dual-mass flywheel can be used "for life", others that it rains very quickly or is not needed at all and can be converted to a conventional flywheel. True, about half way. This is an element that wears out, but if the car is properly maintained and the driver knows how to use the car with this solution, he should have no problems for tens of thousands of kilometers. And what "kills" a dual-mass flywheel? Driving at a very low speed, which generates a strong vibration of the power unit. In this case, the dual-mass wheel works at its limit, reducing vibrations. Fast acceleration from low revs is also very unprofitable - a diesel engine produces high torque even at low revs. This harshness of the gas and inexperienced handling of the clutch leads to the fact that the dual-mass flywheel quickly makes itself felt.

The symptoms of a damaged dual mass flywheel are quite common and you don't need a specialist to pre-diagnose the problem. If obvious vibrations are felt in the car, which are additionally transmitted to the car body, if loud knocks are heard when shifting gears and starting / stopping the engine, most likely the dual-mass flywheel refuses to obey. It is true that you can decide to restore, but it depends on the degree of wear / damage to the double mass and whether an experienced workshop takes care of the maintenance. The cost is from several hundred to several thousand zlotys. A new dual-mass flywheel costs between PLN 1000 and PLN 10.

See also: Testing the Mazda 6