Diesel engines

Design features of diesel engines

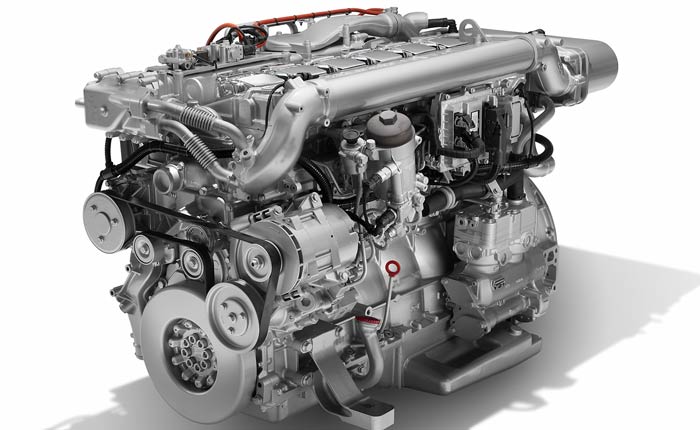

A diesel engine unit is one of the types of piston power plants. In terms of its performance, it is almost no different from a gasoline internal combustion engine. There are the same cylinders, pistons, connecting rods, crankshaft and other elements.

A diesel engine unit is one of the types of piston power plants. In terms of its performance, it is almost no different from a gasoline internal combustion engine. There are the same cylinders, pistons, connecting rods, crankshaft and other elements.

The action of “diesel” is based on the self-ignition property of diesel fuel sprayed into the cylinder space. The valves in such a motor are significantly strengthened - this had to be done in order for the unit to be resistant to increased loads for a long time. Because of this, the weight and dimensions of a “diesel” engine are greater than that of a similar gasoline unit.

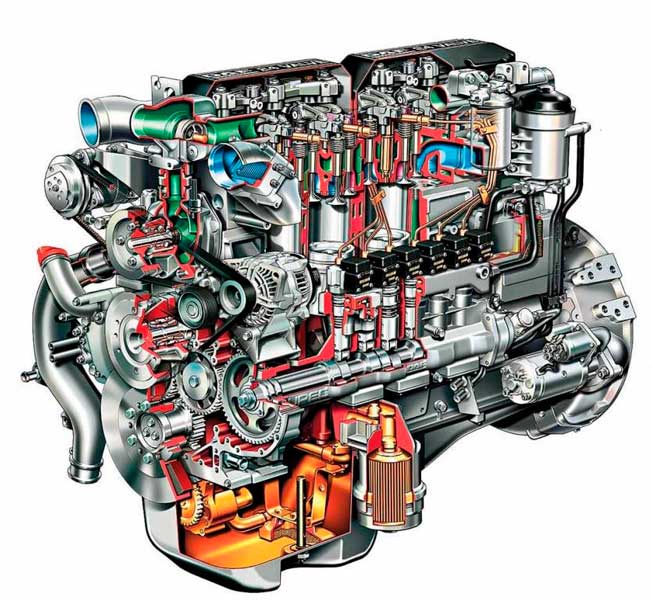

There is also a significant difference between diesel and gasoline mechanisms. It lies in how exactly the air-fuel mixture is formed, what is the principle of its ignition and combustion. Initially, normal clean air flow is directed into the operating cylinders. As the air is compressed, it warms up to a temperature of about 700 degrees, after which the injectors inject fuel into the combustion chamber. High temperature promotes instant spontaneous combustion of fuel. Combustion is accompanied by a rapid build-up of high pressure in the cylinder, so the diesel unit produces a characteristic noise during operation.

Diesel engine start

Starting a diesel engine in a cold state is carried out thanks to glow plugs. These are heating electric elements integrated into each of the combustion chambers. When the ignition is turned on, the glow plugs heat up to extremely high temperatures = about 800 degrees. This heats up the air in the combustion chambers. The whole process takes a few seconds, and the driver is notified by a signal indicator in the instrument panel that the diesel engine is ready to start.

The electricity supply to the glow plugs is automatically cut off approximately 20 seconds after starting. This is necessary to ensure stable operation of a cold engine.

Diesel engine fuel system

One of the most important systems of a diesel engine is the fuel supply system. Its main task is to supply diesel fuel to the cylinder in strictly limited quantities and only at a given moment.

One of the most important systems of a diesel engine is the fuel supply system. Its main task is to supply diesel fuel to the cylinder in strictly limited quantities and only at a given moment.

The main components of the fuel system:

- high pressure fuel pump (high pressure fuel pump);

- fuel injectors;

- filter element.

The main purpose of the injection pump is to supply fuel to the injectors. It works according to a given program in accordance with the mode in which the engine operates and the actions of the driver. In fact, modern fuel pumps are high-tech mechanisms that automatically control the operation of a diesel engine based on the driver's control inputs.

At the moment when the driver presses the gas pedal, he does not change the amount of fuel supplied, but makes changes to the operation of the regulators depending on the force of pressing the pedal. It is the regulators that change the number of engine revolutions and, accordingly, the speed of the machine.

As experts from Favorit Motors Group note, fuel injection pumps of distribution design are most often installed on passenger cars, crossovers and SUVs. They are compact in size, supply fuel evenly to the cylinders and operate efficiently at high speeds.

The injector receives fuel from the pump and regulates the amount of fuel before redirecting the fuel to the combustion chamber. Diesel units are equipped with injectors with one of two types of distributor: type or multi-hole. The distributor needles are made of high-strength, heat-resistant materials because they operate at high temperatures.

The fuel filter is a simple and, at the same time, one of the most important components of a diesel unit. Its operating parameters must exactly correspond to the specific type of engine. The purpose of the filter is to separate condensate (the lower drain hole with a plug is intended for this) and eliminate excess air from the system (the upper booster pump is used). Some car models have a function for electric heating of the fuel filter - this makes it easier to start a diesel engine in winter.

Types of diesel units

In the modern automotive industry, two types of diesel power plants are used:

- direct injection engines;

- diesel engines with a separate combustion chamber.

In diesel units with direct injection, the combustion chamber is integrated into the piston. Fuel is injected into the space above the piston and then directed into the chamber. Direct fuel injection is typically used on low-speed, large-displacement powerplants where ignition issues are difficult.

Diesel engines with a separate chamber are more common today. The combustible mixture is injected not into the space above the piston, but into an additional cavity that is located in the cylinder head. This method optimizes the self-ignition process. In addition, this type of diesel engine operates with less noise even at the highest speeds. These are the engines that are installed today in cars, crossovers and SUVs.

Diesel engines with a separate chamber are more common today. The combustible mixture is injected not into the space above the piston, but into an additional cavity that is located in the cylinder head. This method optimizes the self-ignition process. In addition, this type of diesel engine operates with less noise even at the highest speeds. These are the engines that are installed today in cars, crossovers and SUVs.

Depending on the design features, the diesel power unit operates in four-stroke and two-stroke cycles.

The four-stroke cycle involves the following stages of operation of the power unit:

- The first stroke is the rotation of the crankshaft 180 degrees. Due to its movement, the intake valve opens, as a result of which air is supplied to the cylinder cavity. After that, the valve closes abruptly. At the same time, at a certain position, the exhaust (release) valve also opens. The moment of simultaneous opening of the valves is called overlap.

- The second stroke is the compression of air by the piston.

- The third measure is the beginning of the move. The crankshaft rotates 540 degrees, the fuel-air mixture ignites and burns out when it comes into contact with the injectors. The energy released during combustion enters the piston and causes it to move.

- The fourth cycle corresponds to the rotation of the crankshaft up to 720 degrees. The piston rises and ejects the spent combustion products through the exhaust valve.

The two-stroke cycle is usually used when starting a diesel unit. Its essence lies in the fact that the air compression strokes and the beginning of the working process are shortened. In this case, the piston releases exhaust gases through special inlet ports during its operation, and not after it goes down. After taking the initial position, the piston is purged to remove residual effects from combustion.

Advantages and disadvantages of using diesel engines

Diesel fuel power units are characterized by high power and efficiency. Specialists from Favorit Motors Group note that cars with diesel engines are becoming more and more in demand every year in our country.

Firstly, due to the peculiarities of the fuel combustion process and the constant release of exhaust gases, diesel does not impose strict requirements on fuel quality. This makes them more economical and affordable to maintain. In addition, the fuel consumption of a diesel engine is less than that of a gasoline unit of the same volume.

Secondly, spontaneous combustion of the fuel-air mixture occurs evenly at the moment of injection. Therefore, diesel engines can operate at lower speeds and, despite this, produce very high torque. This property makes it possible to make a vehicle with a diesel unit much easier to drive than a car that consumes gasoline fuel.

Thirdly, the used gas exhaust from a diesel engine contains much less carbon monoxide, which makes the operation of such cars environmentally friendly.

Despite their reliability and high engine life, diesel power units fail over time. Favorit Motors Group of Companies technicians do not recommend carrying out repair work on your own, because modern diesel engines are high-tech units. And their repair requires special knowledge and equipment.

Favorit Motors car service specialists are qualified craftsmen who have completed internships and training in the training centers of manufacturing plants. They have access to all technological documentation and have many years of experience in repairing diesel units of any modification. Our technical center has all the necessary equipment and specialized tools for diagnosing and repairing diesel engines. In addition, the restoration and repair services for diesel engines provided by Favorit Motors Group of Companies are easy on the wallets of Muscovites.

Car service experts note that the longevity of a diesel engine directly depends on how timely and high-quality service is carried out. At the Favorit Motors technical center, routine maintenance is carried out in strict accordance with the manufacturer’s flow charts and using only high-quality certified spare parts.