The other side of the cut. Cylinder deactivation system

Vehicle users want their vehicles to consume as little fuel as possible. Therefore, car manufacturers must meet these expectations, in particular by offering new solutions to reduce combustion.

Vehicle users want their vehicles to consume as little fuel as possible. Therefore, car manufacturers must meet these expectations, in particular by offering new solutions to reduce combustion.

Downsizing has been gaining popularity in the engine industry for several years now. We are talking about reducing the power of engines and increasing their power at the same time, that is, applying the principle: from low power to high power. For what? It is in order to reduce fuel consumption, and at the same time reduce the emission of harmful chemical compounds in the exhaust gases. Until recently, it was not easy to balance a small engine size with an increase in power. However, with the spread of direct fuel injection, as well as improvements in turbocharger design and valve timing, downsizing has become commonplace.

Downsizing engines are offered by many major car manufacturers. Some even tried to reduce the number of cylinders in them, which translates into lower fuel consumption.

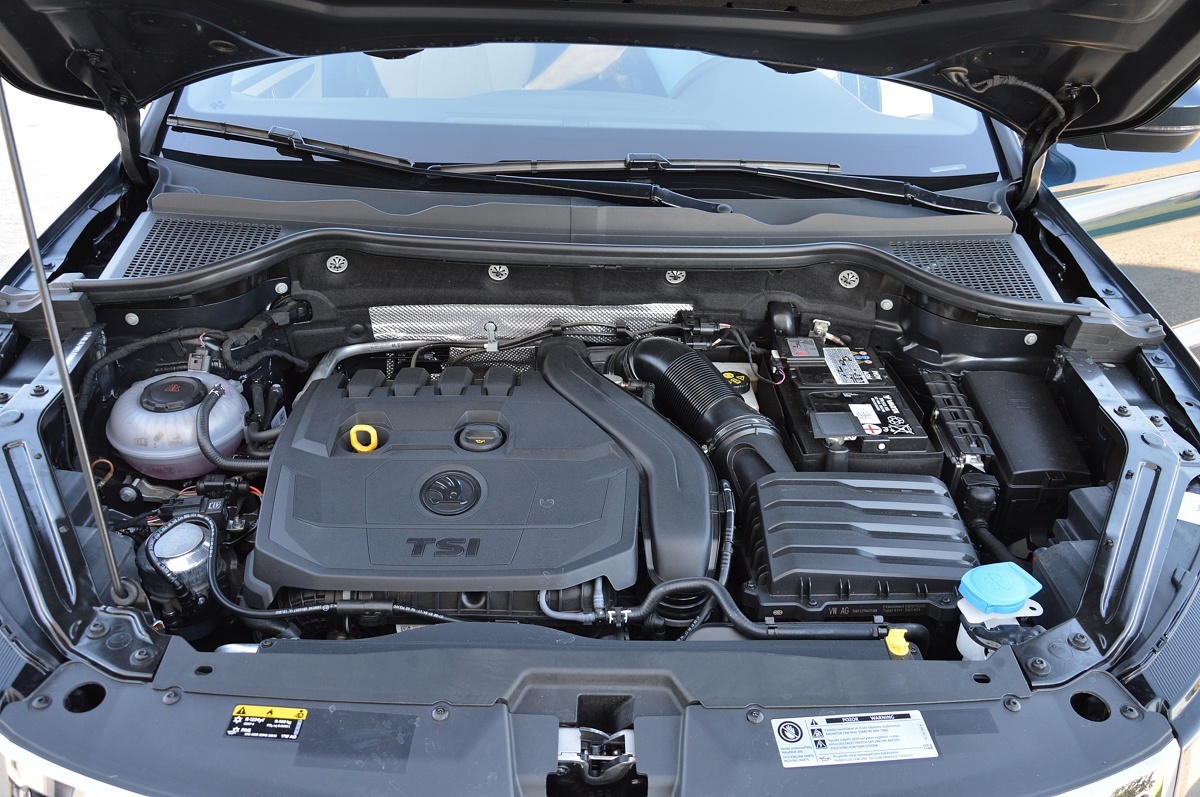

But there are other modern technologies that can reduce fuel consumption. This is, for example, the cylinder deactivation function that was used in one of the Skoda engines. This is a 1.5 TSI 150 hp petrol unit used in the Karoq and Octavia models, which uses the ACT (Active Cylinder Technology) system. Depending on the load on the engine, the ACT function deactivates two of the four cylinders specifically to reduce fuel consumption. The two cylinders are deactivated when full engine power is not needed, such as when maneuvering in a parking lot, when driving slowly, and when driving on the road at a constant moderate speed.

But there are other modern technologies that can reduce fuel consumption. This is, for example, the cylinder deactivation function that was used in one of the Skoda engines. This is a 1.5 TSI 150 hp petrol unit used in the Karoq and Octavia models, which uses the ACT (Active Cylinder Technology) system. Depending on the load on the engine, the ACT function deactivates two of the four cylinders specifically to reduce fuel consumption. The two cylinders are deactivated when full engine power is not needed, such as when maneuvering in a parking lot, when driving slowly, and when driving on the road at a constant moderate speed.

The ACT system was already used a few years ago in the 1.4 hp Skoda Octavia 150 TSI engine. It was the first engine with such a solution in this model. It also later found its way into the Superb and Kodiaq models. A number of amendments and modifications have been made to the 1.5 TSI unit. According to the manufacturer, the stroke of the cylinders in the new engine is increased by 5,9 mm while maintaining the same power of 150 hp. However, compared to the 1.4 TSI engine, the 1.5 TSI unit has more flexibility and faster response to the movement of the accelerator pedal. This is due to the turbocharger with variable blade geometry, specially prepared for operation at high exhaust gas temperatures. On the other hand, the intercooler, that is, the cooler of the air compressed by the turbocharger, is designed in such a way that it can cool the compressed cargo to a temperature of only 15 degrees above the ambient temperature. This will allow more air to enter the combustion chamber, resulting in better vehicle performance. In addition, the intercooler has been moved ahead of the throttle.

The petrol injection pressure has also been increased from 200 to 350 bar. Instead, the friction of the internal mechanisms has been reduced. Among other things, the crankshaft main bearing is coated with a polymer layer. Cylinders, on the other hand, have been given a special structure to reduce friction when the engine is cold.

Thus, in the 1.5 TSI ACT engine from Skoda, it was possible to apply the idea of downsizing, but without the need to reduce its displacement. This powertrain is available on the Skoda Octavia (limousine and station wagon) and the Skoda Karoq in both manual and dual-clutch automatic transmissions.