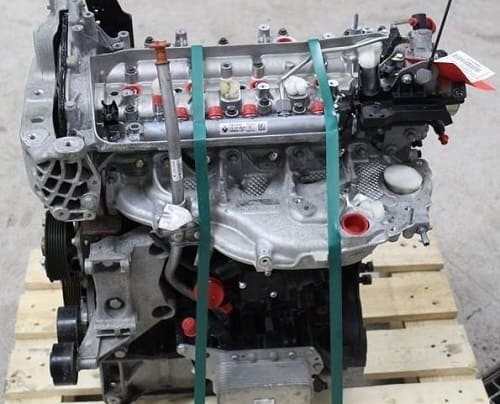

Mercedes-Benz OM622 or 626 engine

Content

A series of in-line 4-cylinder diesel units produced by the Daimler concern in cooperation with the Renault-Nissan alliance. OM622 engines have been produced since 2014, equipped with a start-stop system (depending on the model) and additional equipment.

What is the difference between the 622nd and 626th

The 626th has a longitudinal arrangement and is combined with rear-wheel drive. The power of the unit implies two levels: 115 hp. With. and 136 l. With. Diesel fuel consumption, according to the manufacturer, should not exceed 4,3 liters / 100 km in the combined cycle.

622nd - this is the name of the version with reduced technical capabilities, intentionally made for minibuses. However, this motor is already installed transversely, and the drive is front-wheel drive. The power of the unit is 65-84 kW.

Description of technical parameters

The new motor is equipped with a double flywheel, a universal control unit with additional options and an exhaust control system. It was first introduced on a Mercedes C-class, and then in the same year migrated under the hood of a minibus with the same name OM622.

The working volume of the engines of this family is 1598 cm3. The units are equipped with the Common Rail CDI system. The fuel pressure in this case reaches 1600 bar. The free space between the cylinders is well thought out. It is 88 mm.

The engine is equipped with a cast iron crankcase, the cylinder head is made of aluminum alloy. The pistons are made of steel, which is a feature of these engines, because most modern diesel installations use aluminum pistons. Timing - DOHC type. In other words, it's 4 valves per cylinder and two overhead camshafts.

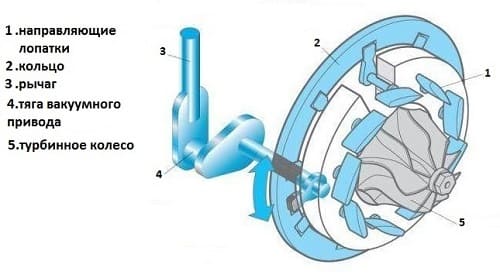

The exhaust system uses a VTG variable length rotary unit. The turbine size is 37,5 mm. The movement of the turbocharger blades is controlled by a vacuum chamber. The latter receives signals from the electric converter BU. The exhaust is also equipped with an EGR valve. First, the exhaust gases enter the filter, are cooled, and then fed to the compressor. Then a selective neutralizer processes them. All this is done with the aim of meeting European environmental standards as much as possible.

| OM622 | ||

|---|---|---|

| DE16 THE 109 CDI | ||

| Power and torque | 85 kW (115 hp) at 3000-4600 rpm, torque: 280 Nm at 1500-2800 rpm | 65 kW (88 hp) at 3800 rpm, torque: 230 Nm at 1500-2000 rpm |

| Years of production | 2014 – 2015 Feet | 2014 – 2015 Feet |

| Cars in which it was installed | C180, C180d | Mercedes-Benz Vito |

| DE16 THE 111 CDI | ||

| Power and torque | 100 kW (136 hp) at 3800 rpm, torque: 320 Nm at 1500-2600 rpm (automatic transmission); torque: 300 Nm at 1500-3000 rpm (manual transmission) | 84 kW (114 hp) at 3800 rpm, torque: 270 Nm at 1500-2500 rpm |

| Years of production | 2014 – 2015 Feet | 2014 – 2015 Feet |

| Cars in which it was installed | C200, C200d | Mercedes-Benz Vito |

Modifications

The engine series has several modifications: OM622, OM628, OM629, OM640.

| Modification | 622 | 628 | 629 | 640 |

|---|---|---|---|---|

| Engine displacement, cc | 1598 | 3996 | 3996 | 1991 |

| Maximum power, hp | 88 – 114 | 250 – 260 | 314 – 320 | 109 |

| Maximum torque, N * m (kg * m) at rpm. | 230(23)/2000; 270 (28) / 2500 | 560 (57) to 2600 | 730 (74) to 2200 | 250 (26) to 2600 |

| Fuel used | Diesel fuel | Diesel fuel | Diesel fuel | Diesel fuel |

| Fuel consumption, l / 100 km | 6,4 | 9.6 – 12.8 | 9,4 | 5,4 |

| engine's type | Inline, 4-cylinder | V-shaped, 8-cylinder | V-shaped, 8-cylinder | Inline, 4-cylinder |

| Engine features | DOHC | DOHC | DOHC, DPF | Unusually high piston stroke |

| Number of valves per cylinder | 4 | 4 | 4 | 2 |

| Maximum power, h.p. (kW) at rpm | 114(84)/3800; 88 (65) / 3800 | 250(184)/4000; 260 (191) / 4000 | 314(231)/3600; 320 (235) / 3600 | 109 (80) to 4200 |

| Supercharger | Turbine | Twin turbocharging | Twin turbocharging | Turbine |

| CO2 emission in g / km | 253 – 340 | 194 – 247 | 128 – 138 | |

| Cylinder diameter, mm | 80 | 86 | 86 | 83 |

| Compression ratio | 15.4 | 18.5 | 16.7 – 17.5 | 18 |

| The piston stroke, mm | 79,5 | 86 | 86 | 92 |

| Mastiff | Recently I went through the same m628. There are a lot of places on the wiring where the appearance of jambs is possible. The wiring of the motor harness is made with thick wires, it does not bend well, they break off the insulation at the very entrance to the plug. The coolant sensor had a short at the client, there were similar problems. The plug also went to the block of glow plugs in the collapse of the cylinders. I have not yet seen a more powerful motor. IMHO |

| Oleg 111 | there the wiring is done perfectly, it bends as it should, the insulation does not break off, questions can arise only after crooked hands on the 628 motor, the output stage of the glow plugs is not installed in the collapse of the block, but on the right head above the gene for 16 years of repairing these motors, I didn’t see anything better , everything is thought out to the smallest detail, honor and praise to German designers |

| Shurik | The location of the intercooler in the variation on the gelendvagen is especially thought out))) it is very convenient to change the belt, for example)))) will you also praise the designers? And the output stage with drying electrolytes is also a magical topic, a convenient place was invented for location. Not a motor but raw meat. But if you like to develop the mobility of your hands and are not afraid of the task of replacing caps and seals through the exhaust pipe, then I do not argue))) |

| Mastiff | But for iron, the motor is really not bad. The sleeves are replaceable, the pastels of the shafts are replaceable, the compensators are not in the rocker arms, the general mechanics are on top. The only thing I didn’t like was the presence of a balance shaft and the absence of a front cover for quick replacement of shoes. And of course the blocky bottom of the crankshaft pastels. |

| Lacha | But seeing, for example, injector ramp mountings not cast on the body of the heads, numerous transitional fasteners, a lot of additional screws and brackets, it is clear that the motor is unfinished. The injector mounts were amazing. It looks like a lepilovo incomprehensible, especially the aluminum protection of the return pipes of the injectors. I compare with diesel engines of w123; 126; 124; 140 series cars. Therefore, this product causes a lot of contradictions. |

| Mastiff | If a normal plunger high-pressure fuel pump were installed on the m628, similar to the engines of previous years, then it seems to me that it would just turn out to be a knock-out motor. |