Mercedes-Benz OM642 engine

Content

A series of 6-cylinder V-shaped diesel engines. Fuel injection is direct, carried out through a turbocharger of its own production. The motor has been produced since 2005, designed to replace the OM647 engine.

General data about the OM642 motor

For greater efficiency of the power plant, the manufacturer has introduced the use of new cylinders since 2014. Their walls were nano-coated. This gave greater efficiency in the use of fuel and reduced the weight of the engine.

The OM642 has a 72-degree camber angle and is equipped with a 3rd generation Common Rail piezo injector capable of delivering 1600 bar. This engine has found application: Bluetooth technology, an intercooler and a new generation turbocharger.

The compression ratio of the 642 is 18 to 1. The timing mechanism is a DOHC type, with two camshafts, there are 4 valves for each cylinder. The timing drive is implemented through a metal chain. The cylinder block and pistons are made of refractory material - aluminum alloy. Two camshafts are placed on each cylinder head. The valves are controlled by a roller type rocker arm.

The engine has an aluminum body, endowed with intersecting struts. The cylinders in it are equipped with cast-iron sleeves, which contributes to significant hardening and reliability of operation. The connecting rods are also strong, steel, and the crankshaft is made of heavy-duty material, with an extensive shaft bearing surface.

| Working volume | 2987 cc cm |

| Maximum power, hp | 224 (air) and 183 – 245 (turbo) |

| Maximum torque, N * m (kg * m) at rpm. | 510 (52) / 1600 (air) and 542 (55) / 2400 (turbo) |

| Fuel used | Diesel fuel |

| Fuel consumption, l / 100 km | 7,8 (air) and 6.9 – 11.7 (turbo) |

| Number of valves per cylinder | 4 |

| Maximum power, h.p. (kW) at rpm | 224 (165) / 3800 (air) and 245 (180) / 3600 (turbo) |

| Gas distribution mechanism | DOHC, 4 valves per cylinder |

| Valve train chain | roller chain |

| Engine electronic control unit | Bosch EDC17 |

| Crankcase | made of die-cast aluminium, with cross brace |

| Crankshaft | forged, made of tempered steel with a wide bearing surface of the main journal |

| Connecting rods | made from forged steel |

| Engine weight | 208 kg (459 pounds) |

| Injection system | common rail 3 direct fuel injection with piezo injectors, allowing up to 5 injections per cycle |

| injection pressure | up to 1600 bar |

| Turbocharger | VTG Variable Turbine Geometry |

| Environmental standards | Euro-4, Euro-5 |

| Exhaust system | EGR exhaust gas recirculation system |

| Technology used | BlueTEC |

| Versions | DE30LA , DE30LA red. and LSDE30LA |

| CO2 emission in g / km | 169 – 261 |

| Cylinder diameter, mm | 83 – 88 |

| Compression ratio | 16.02.1900 |

| The piston stroke, mm | 88.3 – 99 |

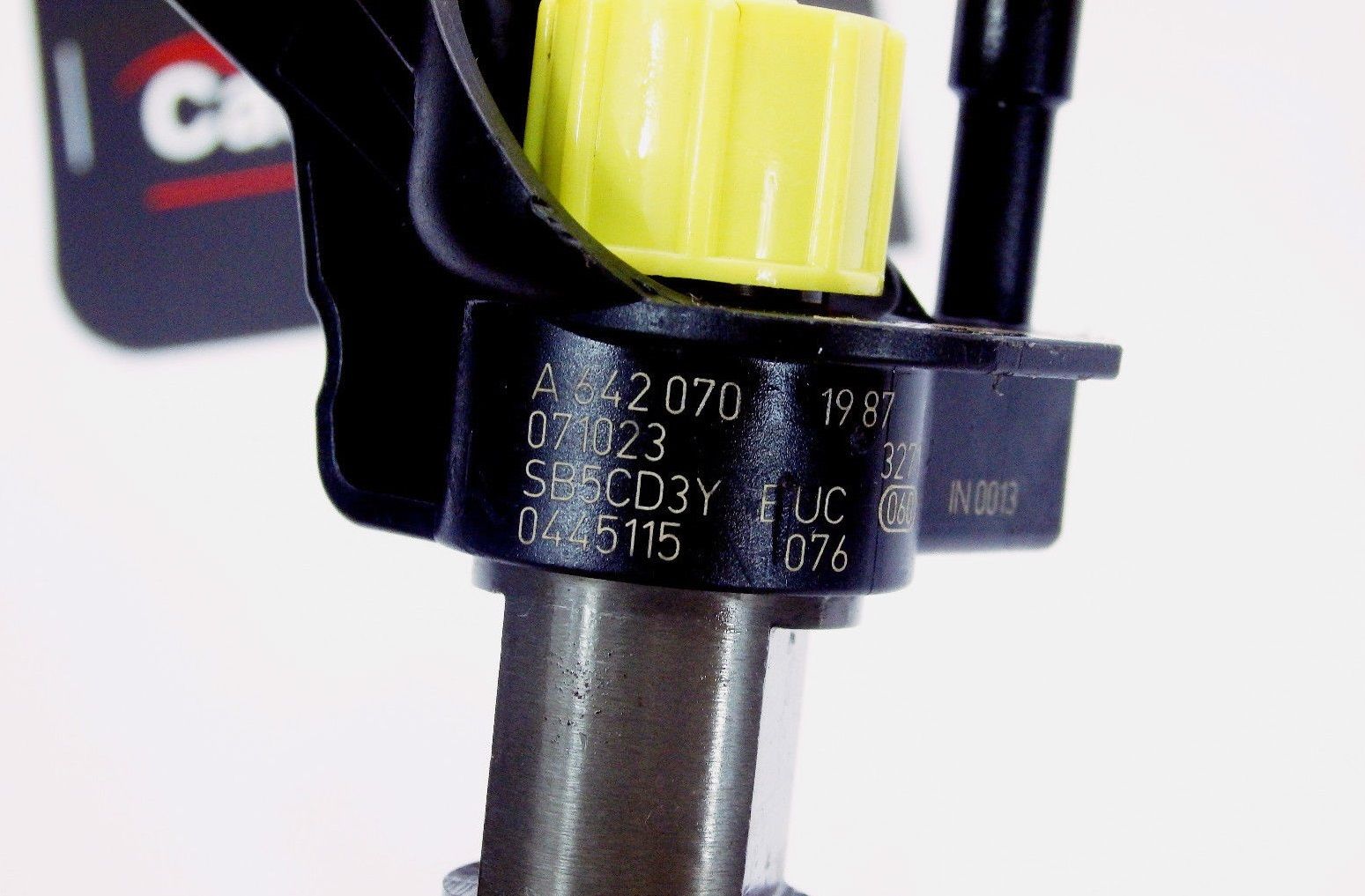

Injector OM642

The injection system is based on the work of piezoelectric elements. Such an injector is capable of producing up to five injections at a time, which reduces fuel consumption and emissions of harmful substances. It also reduces engine noise, improves responsiveness to the accelerator pedal. Together with the VTG turbocharger, the system provides high power and enviable torque already from low revs. The supercharger is electronically controlled and adjusted, so metering and boost errors are minimal here.

Features of injectors of this type:

- injection is controlled by a Bosch electronic control unit;

- injectors are made in the form of nozzles, have eight holes;

- pressurization is carried out by a VTG compressor with a variable turbine length;

- the intake manifold is equipped with an additional channel for the passage of air, which also increases the power of the unit and improves the charge change;

- a special air cooler allows you to reduce the flow temperature if it exceeds 90-95 degrees.

Exhaust controlled by a separate system

AGR is a separate exhaust cooling system. It is used to improve the environmental standards of the motor. Several parts are involved in the work at the same time:

- the filter is restored without the use of additional elements - this task is assigned to the internal combustion engine control system;

- a selective type catalyst traps ammonia produced during the combustion of diesel fuel, preparing the substance for a further reaction to reduce emissions;

- at the same time, the SCR acts as a filter that traps sulfur odors and so on.

Thus, the operation of the entire cleaning system based on Bluetec technology is ensured.

Typical malfunctions

A bunch of various sensors, adjustable air intake, the ability to relieve excess pressure - unfortunately, all this does not guarantee the trouble-free operation of this unit.

- If you are not careful about the cleanliness of the engine, it may not reach the end of its operational life. So, the inlet must be washed from traces of oil that enters due to incorrect operation of the turbine. The manufacturer himself strongly recommends: when replacing the turbine, it is necessary to check and remove oil from the intake system!

- Lubricant can also enter the intake along with the exhaust gases. This is already explained by a constructive miscalculation, especially if the oil enters in large quantities. The solution is to carry out repairs by thoroughly cleaning the intercooler.

- From getting inside the intake manifold of oil, the internal channels are coked. A malfunction occurs in the damper system, which, oddly enough, is recognized by the German manufacturer as a completely normal practice.

- Despite the use of cool and modern software, when the maximum speed is exceeded, the control unit is not able to protect the engine from destruction. The computer is simply not able to lock the throttle, although it is possible to limit the power and turn off the boost when the turbine is overboosted.

Otherwise, this is an excellent engine in terms of mechanics. With a weight of more than 200 kg, the engine produces 260 hp. With. and 600 Nm of torque. The timing chain is of high quality, does not deteriorate. Seizures in the cylinders are very rare, and there are practically no problems in the valve mechanism. In a word, this motor is completely different from those engines that are made only taking into account environmental standards. Most modern units are just like that - with a complex design and unreliable.

Modifications

The OM642 engine has several modifications. All of them have the same working volume, equal to 2987 cm3.

| Power and torque | 135 kW (184 hp) at 3800 rpm and 400 Nm at 1600-2600 rpm; 140 kW (190 hp) at 4000 rpm and 440 Nm at 1400-2800 rpm; 140 kW (190 hp) at 3800 rpm and 440 Nm at 1600-2600 rpm; 150 kW (204 hp) at 4000 rpm and 500 Nm at 1400-2400 rpm |

| Years of issue | 2005-2009, 2006-2009, 2009-2012, 2007-2013 |

| Cars in which it was installed | Sprinter 218 CDI/318 CDI/418 CDI/518 CDI, G 280 CDI, G 300 CDI, ML 280 CDI, ML 300 CDI BlueEFFICIENCY, E 280 CDI, R 280 CDI, R 300 CDI, R 300 CDI BlueEFFICIENCY, Sprinter 219 CDI /319 CDI/419 CDI/519 CDI, Sprinter 219 BlueTEC/519 BlueTEC, Viano 3.0 CDI/Vito 120 CDI |

| Power and torque | 155 kW (211 hp) at 3400 rpm and 540 Nm at 1600-2400 rpm; 165 kW (218 hp) at 3800 rpm and 510 Nm at 1600 rpm; 165 kW (224 hp) at 3800 rpm and 510 Nm at 1600-2800 rpm; 170 kW (231 hp) at 3800 rpm and 540 Nm at 1600-2400 rpm; 173 kW (235 hp) at 3600 rpm and 540 Nm at 1600-2400 rpm |

| Years of issue | 2007-2009, 2009-2011, 2010-2015 |

| Cars in which it was installed | GL 350 BlueTEC, E 300 BlueTEC, R 350 BlueTEC, G 350 BlueTEC, Chrysler 300C, ML 320 CDI, GL 320 CDI, GL 350 CDI BlueEFFICIENCY, C 320 CDI, GLK 320 CDI, C 350 CDI BlueEFFICIENCY, S 350 CDI BlueEFFICIENCY |

| Power and torque | 170 kW (231 hp) at 3800 rpm and 540 Nm at 1600-2400 rpm; 180 kW (245 hp) at 3600 rpm and 600 Nm at 1600-2400 rpm; 185 kW (252 hp) at 3600 rpm and 620 Nm at 1600-2400 rpm; 190 kW (258 hp) at 3600 rpm and 620 Nm at 1600-2400 rpm; 195 kW (265 hp) at 3800 rpm and 620 Nm at 1600-2400 rpm |

| Years of issue | 2011-2013, 2013-2014, 2010-2012 |

| Cars in which it was installed | E 300 CDI BlueEFFICIENCY, G 350 d, E 350 BlueTEC, CLS 350 BlueTEC 4MATIC, ML 350 BlueTEC, S 350 BlueTEC |

| Cat 66 | In general, the OM 642 motor has proven itself to be quite reliable. Sores begin to appear at mileages of 150-200 thousand, although more and more I see cars with a twisted mileage of 100-120 thousand. And the surprise of the owner of the car is always pleasing: “How come, a friend sold it to me, this can’t happen!! But in the end, the car owner spends a tidy sum on repairs only because, when buying a car, he did not bother to do normal diagnostics of the car from the officials or in a normal certified service center, trusting a friend or private person. Dear forum users, when buying a car for 1000000 or more, find 5-10 thousand for comprehensive diagnostics, I assure you this will save you from many problems and save you a tidy sum. Let's return to the topic of the post, at mileages of 150-200, the auxiliary systems of the engine begin to fail, as a result of the failure of components such as the oil pump, turbine breakdown due to low oil pressure, souring of the swirl flap rods and their subsequent jamming, failure of the crankcase ventilation system and exit from building a particulate filter. |

| Master | The main thing to remember for all owners of diesel engines, be it Mercedes, BMW, Toyota or any other brand "Diesel engine is not economy, it's just installment life". The first thing that starts to fail on this engine is the crankcase ventilation system. It's not a secret for anyone, although our country is one of the major producers of natural resources, it frankly supplies SUROGATS to its consumers. Hence the short life of engine oil. I will make a reservation right away, I advise you to change the oil on this motor every 7500 thousand. Urban type of car operation, adversely affects the motor. Constant pushing in traffic jams, and an average speed in the city of 60 km does not allow the engine to catch its breath; hence, a large amount of deposits in the crankcase ventilation pipes, in the air intake. |

| Roma | I advise owners of cars with this type of engine on a run of 100-120 thousand, service the air intake system, intake manifold, air intake pipe. Clean all of the above from oil deposits and you will not recognize your car. Since if this is not done, all this enters the intake manifold and settles on the dampers. If we say it is run, then by about 150-200 mileage, depending on the type of ride, the swirl flaps begin to wedge and eventually break them off. |

| Anadyr | Exactly! The swirl flap servo also fails, for the most part due to oil getting on it from under the rubber inlet pipe. Dear members of the forum, change the two red rubber bands of the intake pipe and the ventilation pipe every 20 thousand km. Yes, I understand the price of one 800 another 300, it seemed not a lot of money “BUT S.KA SHE doesn’t flow, why change it?” When it flows, and it will flow, it will be too late. The price tag is also not small now I will understand those who have already changed it. |

| Zarikov | In my opinion, one of the main faults of the OM642 is the failure of the injectors. The car starts to smoke, loses power, difficult to start in the morning. Of course, there may be glow plugs then you got off with a slight fright, but for the most part, for runs of 150, these are already injectors. They are not repairable! Here, too, I want to make a reservation and warn! Of course, I don’t know how it is in other regions of Russia, but Moscow is full of offices that promise you mountains of gold for 6500-7000. Divorce!!!! For the most part, offices are buying used ones. forces abroad and by disassembling them restore customers' engines. The warranty for such offices is usually a month or two. The nozzles themselves have a piezo element that cannot be restored; from a bad solarium, the life of the nozzle is significantly reduced. For example, if in Europe the life of injectors is 300 thousand, then we have 150. In general, the maximum that can be done with injectors, provided that the piezoelectric element is alive, is to change the atomizers. |

| Know-it-all | The problem with this motor is the failure of the oil pump. Frankly, there were OM 642 motors in which they really refused giving out low oil pressure, but as a rule, the runs on such motors were deep over 200. For the most part, the problem with the failure of the oil pump was invented by the left-handed services. As a rule, pump failure occurs after replacing the oil cooler gaskets. Until 2014, the gaskets for the oil cooler were of poor quality, so on runs of 120-140 oil began to flow from the collapse of the engine. |

| The Crimean | all in all true |

| Pahel | Is there no such review for ML 350, w164 272 motor? And then I have one of the office cars (2006) for 1,5 years with cut collector flaps. I'm thinking about changing the manifold or already hammering it)) I'm sorry that it's off topic! Here from the "great masters" you will not expect any sensible answer)) |

| Cat 66 | At the expense of dampers, I removed them and God bless him, the only expense will increase, that's the only nuance. Some are being programmatically removed by the shutters. If you removed it correctly, glued the intake normally, ride and pay no attention. Moreover, as I understand it, the fuel is state-owned ... |

| George Pavel | For 642 094 05 80 The inlet pipe gasket has a different number 02 10183А/2 Do not tell me how to understand this? |

| Groin | Everything is great, you just need to write the letter A in English, not Russian)) |

| Anton R | Tell me what gaskets for the turbine, number. What else is worth buying for this procedure.Wdc1648221a651034 |

| Cat 66 | A 642 142 32 80 left exhaust gasket – 1 pc. A 642 142 31 80 right exhaust gasket A 642 142 07 81 cylinder head support gasket – 1 pc. A 014 997 64 45 O-ring – 1 pc. A 642 091 00 50 inserts for the intake flap servomotor – 4 pcs. This is what concerns removing the turbine. You can take a non-original from Erling or Viktor Rinze. The second goes to the factory. |

| Kuyter | That's how much I haven't looked for info about this motor - everywhere they write about troubles on ML and GL, but I can’t find almost anything on 221 ... Do they break down less often or complain less often on the Internet?) In theory, the car is not lighter than 164 bodies of the same ... |

| Cat 66 | The OM 642 engine until 2012, regardless of where it was installed due to illness, is absolutely the same. 221 with a diesel engine for Moscow, let's say a rarity. More gasoline, I don’t know if it’s because of the established values that the business class should be representative, not a tractor. Toli to the best of economy. There is little information on this on the Internet. |

| Kuyter | Where is the best place to run it? The previous one only poured diesel on BP for the last couple of years ... This is my first diesel, I always poured benzes just on Gazprom / Lukoil ... I also wonder what oil is best to pour to extend its life, given that I plan to change it every 5 km (with such a frequency would like something optimal in terms of price / quality). |

| Cat 66 | I can say for sure not castrol, mobil 50-50 depending on where you buy it. In any case, the mobile phone can check the batch for counterfeit. Well, there are no comrades for the taste and color, the main thing is that the oil is within the tolerances of the permitted MB and is necessarily designed for a particulate filter. As for the motor, we service it and sort it out and do a lot of other interesting things. That is why we share our experience here, since, unfortunately, there are few specialists in this brand in most of Russia. At the expense of refueling BP, in my opinion, it is not justified to overestimate the price of diesel fuel, I’m not sure about the quality. Lukoil is definitely not. I advise either Gazprom or Rosneft to refuel. The latter have recently launched a new line of fuel processing, as promised by their general fuel should be of the highest category. I personally only Gazprom, there were no complaints. |