Mitsubishi 4m41 engine

Content

The new 4m41 engine appeared in 1999. This power unit was installed on the Mitsubishi Pajero 3. The 3,2-liter engine with an increased cylinder diameter has a crankshaft with a longer piston stroke and other modified parts.

Description

The 4m41 engine is powered by diesel fuel. It is equipped with 4 cylinders and the same number of valves per cylinder. The block is protected by a new aluminum head. Fuel is supplied by a direct injection system.

The engine design is standard for two-camshaft designs. The intake valves are 33mm and the exhaust valves are 31mm. The valve stem thickness is 6,5 mm. The timing drive is a chain, but it is not as reliable as on a 4m40 (it starts to make noise closer to the 150th run).

4m41 is a turbocharged engine with an MHI blower installed. Compared to the predecessor 4m40, the designers managed to increase power (it reached 165 hp), torque in all ranges (351 Nm / 2000 rpm) and improve environmental performance. Of particular importance was the reduction in fuel consumption.

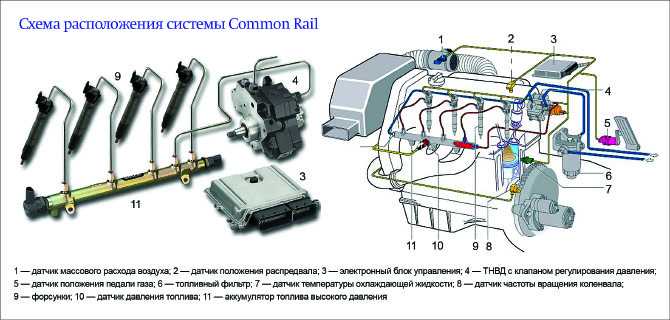

Since 2006, the production of the upgraded 4m41 Common Rail began. The turbine, accordingly, changed to IHI with variable geometry. The intake ducts have been redesigned, a new intake manifold with swirl phases has been installed and the EGR system has been improved. All this made it possible to increase the environmental class, add power (now it has become 175 hp) and torque (382 Nm / 2000).

After another 4 years, the engine was again modified. The power of the unit increased to 200 liters. with., torque - up to 441 Nm.

In 2015, 4m41 became obsolete and was replaced by 4n15.

Technical specifications

| Winemaking | Kyoto engine plant |

| Engine make | 4M4 |

| Years of issue | 1999-NV. |

| Cylinder block material | cast iron |

| engine's type | diesel |

| Configuration | in-line |

| Number of cylinders | 4 |

| Valves per cylinder | 4 |

| The piston stroke, mm | 105 |

| Cylinder diameter, mm | 98.5 |

| Compression ratio | 16.0; 17.0 |

| Engine displacement, cc | 3200 |

| Engine power, hp / rpm | 165/4000; 175/3800; 200/3800 |

| Torque, Nm / rpm | 351/2000; 382/2000; 441/2000 |

| Turbocharger | MHI TF035HL |

| Fuel consumption, l/100 km (for Pajero 4) | 11/8.0/9.0 |

| Oil consumption, gr. / 1000 km | to 1000 |

| Engine oil | 5W-30; 10W-30; 10W-40; 15W-40 |

| Oil change is carried out, km | 15000 or (better 7500) |

| Engine operating temperature, deg. | 90 |

| Engine resource, thousand km | 400+ |

| Tuning, HP potential | 200+ |

| The engine was installed | Mitsubishi Triton, Pajero, Pajero Sport |

Engine malfunctions 4m41

Problems faced by the owner of a car equipped with 4m41.

- After 150-200 thousandth run, the timing chain starts to make noise. This is a clear signal for the owner - it is necessary to carry out a replacement until it is torn.

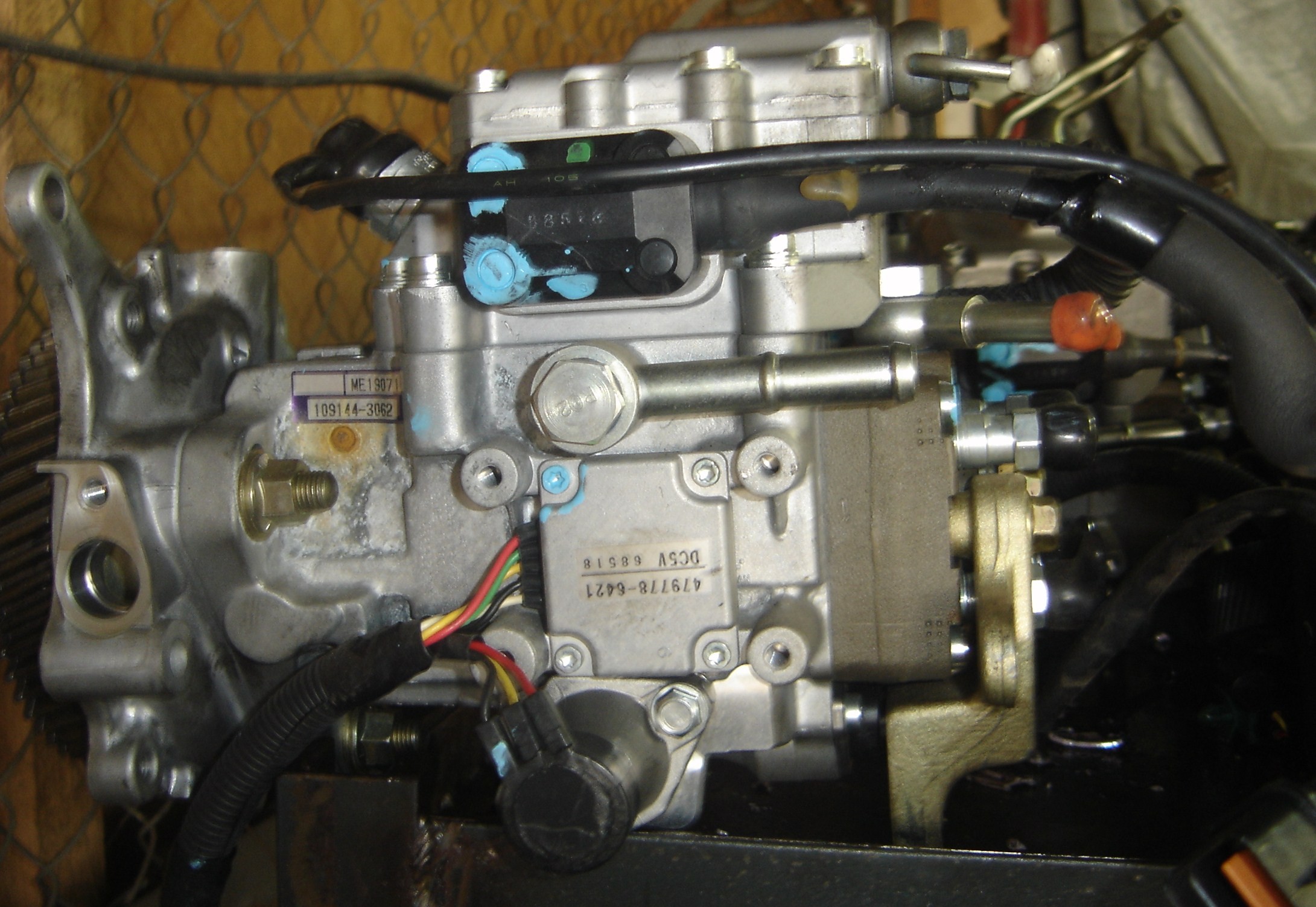

- "Dies" injection pump. The sensitive high pressure pump does not recognize low-grade diesel fuel. A symptom of a non-working pump - the engine does not start or does not start, its power decreases. According to the manufacturer, the high-pressure fuel pump is capable of serving more than 300 thousand kilometers, but only on condition of high-quality fuel and competent service.

- The alternator belt is failing. Because of this, a whistle begins, penetrating into the interior of the car. Usually, belt tension saves for a while, but only replacement finally helps to solve the problem.

- The crankshaft pulley is falling apart. Approximately every 100 thousand kilometers it is necessary to check it.

- Valve adjustment should be carried out every 15 thousand kilometers. The gaps are as follows: at the inlet - 0,1 mm, and at the outlet - 0,15 mm. Cleaning the EGR valve is especially relevant - it does not recognize low-grade fuel, it quickly becomes polluted. Many owners act universally - they simply jam the USR.

- The injector fails. Nozzles are able to work without problems for more than 100-150 thousand km, but after that problems begin.

- The turbine declares itself every 250-300 thousand kilometers.

Chain

Despite the fact that the chain drive looks more reliable than the belt drive, it also has its own resource. Already after 3 years of operation of the car, it is necessary to check the tensioners, dampers and sprockets.

The main causes of rapid chain wear should be looked for in the following:

- in the untimely replacement of motor lubricant or the use of non-native oil;

- in low pressure formed by high pressure fuel pump;

- in the wrong operating mode;

- in poor-quality repairs, etc.

Most often, the tensioner plunger sticks or the check ball valve does not work. The chain breaks due to coking and the formation of oil deposits.

To determine the wear of the chain, when it is still weakening, it is possible by the uniform noise of the engine, which is clearly distinguishable at idle and at "cold". On 4m41, a weak chain tension will cause the part to gradually stretch - the teeth will begin to jump on the sprocket.

However, the most common symptom of a worn chain on a 4m41 is a rattling and dull sound - it manifests itself in the front of the power unit. This noise is similar to the sound of ignition of fuel in cylinders.

A strong stretching of the chain is already clearly distinguishable not only at idle, but also at higher speeds. Long-term operation of a car with such a drive will necessarily lead to:

- to jumping the chain and knocking down the timing marks;

- breakage of the gas distribution mechanism;

- piston damage;

- breaking the cylinder head;

- the appearance of gaps on the surface of the cylinders.

An open circuit is the result of untimely care. This threatens to overhaul the engine. A signal for an urgent replacement of the circuit may be the failure of the starter when starting the engine or a new sound of the starting device that has not been shown before.

Replacing the chain with 4m41 must necessarily imply updating a number of mandatory elements (the table below provides a list).

| Name | Quantity |

| Timing chain ME203085 | 1 |

| Star for the first camshaft ME190341 | 1 |

| Sprocket for second camshaft ME203099 | 1 |

| Twin crankshaft sprocket ME190556 | 1 |

| Hydraulic tensioner ME203100 | 1 |

| Tensioner gasket ME201853 | 1 |

| Tensioner shoe ME203833 | 1 |

| Calm (long) ME191029 | 1 |

| Small top damper ME203096 | 1 |

| Small lower damper ME203093 | 1 |

| Camshaft key ME200515 | 2 |

| Crankshaft oil seal ME202850 | 1 |

TNVD

The main reason for the malfunction of the high-pressure fuel pump on 4m41 is, as mentioned above, the poor quality of diesel fuel. This immediately leads to changes in adjustments, the appearance of new noise and overheating. Plungers can simply jam. This often happens on 4m41 due to water intrusion into the gap. The plunger works as if without lubrication, and from friction it lifts the surface, it heats up and jams. The presence of moisture in diesel fuel causes a corrosive process of the plunger and sleeve.

The injection pump can also deteriorate due to the banal wear of parts. For example, tightness weakens or play increases in movable mates. At the same time, the correct relative position of the elements is violated, the hardness of the surfaces changes, on which carbon deposits gradually accumulate.

Another of the popular high-pressure fuel pump malfunctions is a decrease in fuel supply and an increase in its unevenness. This is caused by the wear of plunger pairs - the most expensive elements of the pump. In addition, plunger leashes, discharge valves, rack clamps, etc. wear out. As a result, the throughput of the nozzles changes, and the engine power and efficiency are impaired.

Injection lag is also a common type of high pressure pump failure. It is also explained by the wear of a number of parts - the roller axis, the pusher housing, ball bearings, camshaft, etc.

Generator belt

One of the main reasons why the alternator belt breaks on 4m41 is the curvature of the pulley installation after the next repair. Incorrect mutual alignment leads to the fact that the belt does not rotate in an even arc and touches various mechanisms - as a result, it quickly wears out and breaks.

Another reason for early wear is a crooked crankshaft pulley. You can determine this malfunction by a dial indicator that allows you to check the beat.

On the plane of the pulley, burrs can form - sagging in the form of metal dots. This is unacceptable, so such a pulley must be ground.

Bearings that have failed are also the cause of a broken belt. They should rotate easily without a belt. Otherwise, it's a spell.

A belt that is about to break or slip off is sure to whistle. Replacing a part without checking the bearings will not work. Therefore, you must first test their work, and only then replace the belt.

Crankshaft pulley

Despite the factory strength, the crankshaft pulley falls apart over time from improper operation or after a long car mileage. The first rule that the owner of a car with a 4m41 engine must remember is not to turn the crankshaft by the pulley!

In fact, the pulley consists of two halves. Excessive loads on this node can lead to a quick breakdown. Signs - a stone steering wheel, a blinking charge light, a knock.

About engines with two camshafts

The camshafts in the engine are placed in the cylinder head. This design is called DOHC - when there is only one camshaft, then SOHC.

Why put two camshafts? First of all, this design is caused by the problem of driving from several valves - it is difficult to do this from one camshaft. In addition, if the entire load falls on one shaft, then it may not withstand and will be considered excessively loaded.

Thus, engines with two camshafts (4m41) are more reliable, as the life of the distribution unit is extended. The load is evenly distributed between two shafts: one drives the intake valves and the other drives the exhaust valves.

In turn, the question arises, how many valves should be used? The fact is that a large number of them can improve the filling of the chamber with a fuel-air mixture. In principle, it was possible to fill through one valve, but it would be huge, and its reliability would be called into question. Several valves work faster, open for a longer time, and the mixture completely fills the cylinder.

If the use of one shaft is meant, then rocker arms or rockers are installed on modern engines. This mechanism links the camshaft to the valve(s). Also an option, but the design becomes more complicated, as many complex details appear.