Nissan QG18DE engine

Content

QG18DE is a successful power plant with a volume of 1.8 liters. It runs on gasoline and is used on Nissan cars, it has a high torque, the maximum value of which is achieved at low speeds - 2400-4800 rpm. This indirectly means that a motor was developed for city cars, since the peak torque at low revs is relevant with a large number of intersections.

The model is considered economical - fuel consumption on the highway is 6 liters per 100 km. In urban mode, consumption, according to various sources, can increase to 9-10 liters per 100 km. An additional advantage of the engine is low toxicity - environmental friendliness is ensured by the use of a neutralizer on the surface of the piston bottom.

In 2000, the unit won the "Technology of the Year" nomination, which confirms its manufacturability and high reliability.

Technical specifications

QG18DE received two modifications - with a cylinder capacity of 1.8 and 1.6 liters. Their fuel consumption is almost the same. The manufacturer used an in-line engine with 4 cylinders and cast-iron sleeves. To increase engine power, Nissan used the following solutions:

- The use of NVCS fluid coupling for phase control.

- Ignition DIS-4 with a coil on each cylinder.

- DOHC 16V gas distribution system (two overhead camshafts).

The technical parameters of the internal combustion engine QG18DE are indicated in the table:

| Manufacturer | Nissan |

| Year of construction | 1994-2006 |

| Cylinder volume | 1.8 l |

| Power | 85.3-94 kW, which is equal to 116-128 hp. with. |

| Torque | 163-176 Nm (2800 rpm) |

| Engine weight | 135 kg |

| Compression ratio | 9.5 |

| Supply system | Injector |

| Power plant type | Inline |

| Number of cylinders | 4 |

| Ignition | NDIS (4 reels) |

| Number of valves per cylinder | 4 |

| Cylinder head material | Aluminium alloy |

| Exhaust manifold material | Cast iron |

| intake manifold material | Duralumin |

| Cylinder block material | Cast iron |

| Bore | 80 mm |

| Fuel consumption | In the city - 9-10 liters per 100 km On the highway - 6 l / 100 km Mixed - 7.4 l / 100 km |

| Fuel | Gasoline AI-95, it is possible to use AI-92 |

| Oil consumption | Up to 0.5 l/1000 km |

| Required viscosity (depends on the air temperature outside) | 5W20 – 5W50, 10W30 – 10W60, 15W40, 15W50, 20W20 |

| Composition | In summer - semi-synthetic, in winter - synthetic |

| Recommended oil manufacturer | Rosneft, Liqui Moly, LukOil |

| Oil volume | 2.7 liters |

| Working temperature | 95 degrees |

| The resource declared by the manufacturer | 250 000 km |

| Real resource | 350 000 km |

| Охлаждение | With antifreeze |

| Antifreeze volume | In models 2000-2002 - 6.1 liters. In models 2003-2006 - 6.7 liters |

| Suitable candles | 22401-50Y05 (Nissan) K16PR-U11 (Dense) 0242229543 (Bosch) |

| Timing chain | 13028-4M51A, 72 pin |

| Compression | Not less than 13 bar, deviation in neighboring cylinders by 1 bar is possible |

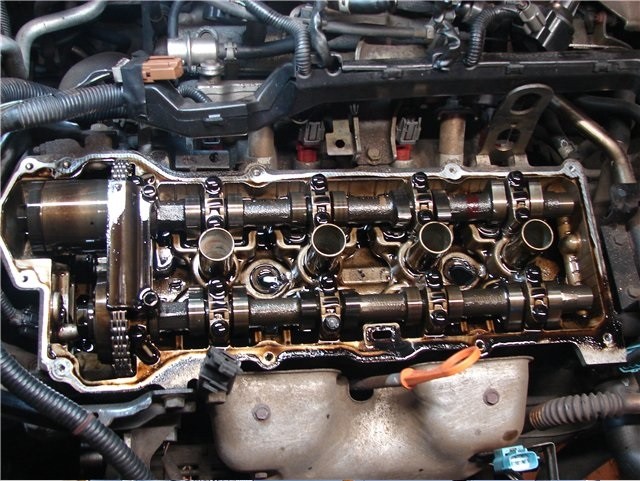

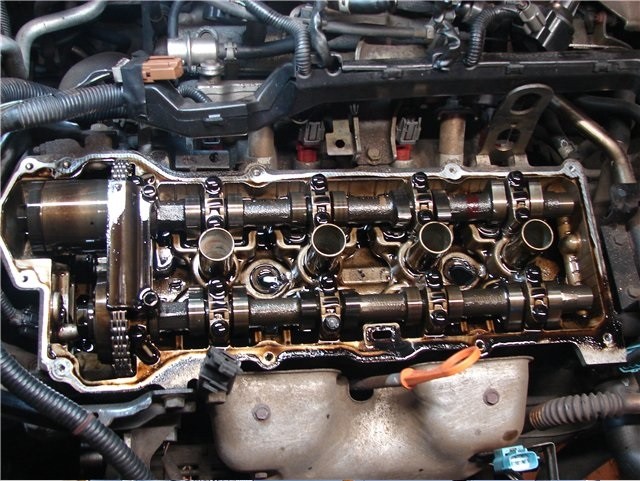

Constructive characteristics

The QG18DE engine in the series received the maximum cylinder capacity. The design features of the power plant are as follows:

- The cylinder block and liners are cast iron.

- The piston stroke is 88 mm, which exceeds the cylinder diameter - 80 mm.

- The piston group is characterized by increased service life due to reduced horizontal loads.

- The cylinder head is made of aluminum and is a 2-shaft.

- There is an attachment in the exhaust tract - a catalytic converter.

- The ignition system received a unique feature - its own coil on each cylinder.

- There are no hydraulic lifters. This reduces the requirements for oil quality. However, for the same reason, a fluid coupling appears, for which the frequency of changing the lubricant is important.

- There are special dampers-swirlers in the intake manifold. Such a system was previously used only on diesel engines. Here, its presence improves the combustion characteristics of the fuel-air mixture, resulting in a decrease in the content of carbon and nitrogen oxides in the exhaust.

Note that the QG18DE unit is a structurally simple unit. The manufacturer provides instructions with detailed illustrations, according to which car owners will be able to overhaul the engine on their own.

Note that the QG18DE unit is a structurally simple unit. The manufacturer provides instructions with detailed illustrations, according to which car owners will be able to overhaul the engine on their own.

Modifications

In addition to the main version, which received distribution injection, there are others:

- QG18DEN - runs on gas (propane-butane mixture).

- QG18DD - version with high pressure fuel pump and direct injection.

The last modification was used on the Nissan Sunny Bluebird Primera from 1994 to 2004. The internal combustion engine used the NeoDi injection system with a high pressure pump (as in diesel plants). It was copied from the GDI injection system previously developed by Mitsubishi. The used mixture uses a ratio of 1:40 (fuel / air), and the Nissan pumps themselves are large and have a long service life.

A feature of the QG18DD modification is the high pressure in the rail in idle mode - it reaches 60 kPa, and at the start of movement it increases by 1.5-2 times. Due to this, the quality of the fuel used plays an extremely important role for the normal operation of the engine, therefore, such modifications are less suitable for Russian conditions compared to classical power plants.

As for gas-powered modifications, Nissan Bluebird cars were not equipped with them - they were installed on Nissan AD Van models of 2000-2008. Naturally, they had more modest characteristics compared to the original - engine power of 105 liters. with., and torque (149 Nm) is achieved at lower speeds.

Advantages and disadvantages

Despite the fact that the device of this internal combustion engine is simple, the motor has received some disadvantages:

- Since there are no hydraulic lifters, from time to time it is necessary to adjust the thermal valve clearances.

- The increased content of harmful substances in the exhaust, which does not allow to comply with the Euro-4 protocol and sell motors in foreign markets. As a result, the engine power was reduced - this made it possible to enter the engine into Euro-4 protocol standards.

- Sophisticated electronics - in the event of a breakdown, you will not be able to figure it out on your own, you will have to contact specialists.

- Requirements for the quality and frequency of oil changes are high.

Pros:

- All attachments are placed very well, which does not interfere with repair and maintenance.

- The cast iron block can be repaired, which significantly increases the life of the engine.

- Thanks to the DIS-4 ignition scheme and swirlers, a reduction in gasoline consumption is achieved and the content of harmful substances in the exhaust is reduced.

- Full diagnostic system - any failure in the operation of the motor is recorded and recorded in the memory of the engine management system.

List of cars with QG18DE engine

This power plant was produced for 7 years. During this time it was used on the following cars:

- The Bluebird Sylphy G10 is a popular front or all wheel drive sedan produced from 1999 to 2005.

- Pulsar N16 is a sedan that entered the markets of Australia and New Zealand in 2000-2005.

- Avenir is a common station wagon (1999-2006).

- Wingroad/AD Van is a utility station wagon that was produced from 1999 to 2005 and was available in the markets of Japan and South America.

- Almera Tino - minivan (2000-2006).

- Sunny is a front-wheel drive sedan popular in Europe and Russia.

- Primera is a car produced from 1999 to 2006 with different body types: sedan, liftback, station wagon.

- Expert - station wagon (2000-2006).

- Sentra B15/B16 ‒ sedan (2000-2006).

Since 2006, this power plant has not been produced, but the cars created on its basis are still on a steady track. Moreover, there are also cars of other brands with QG18DE contract engines, which confirms the versatility of this motor.

Service

The manufacturer gives clear instructions to car owners about the maintenance of the motor. It is unpretentious in care and requires:

- Timing chain replacement after 100 km.

- Valve clearance adjustments every 30 km.

- Fuel filter replacement after 20 km.

- Crankcase ventilation cleaning after 2 years of operation.

- Oil change with filter after 10 km. Many owners recommend changing the lubricant after 000-6 thousand kilometers due to the proliferation of fake oils on the market, the technical characteristics of which do not match the original ones.

- Change the air filter every year.

- Antifreeze replacement after 40 km (additives in the coolant become ineffective).

- Spark plug replacement after 20 km.

- Cleaning the intake manifold from soot after 60 km.

Malfunctions

Every engine has its own problems. The QG18DE unit has been well studied, and its characteristic faults have long been known:

- Antifreeze leakage is the most common failure. The reason is the wear of the idle valve gasket. Replacing it will solve the problem with coolant leakage.

- Increased oil consumption is the result of poor oil scraper rings. In most cases, they need to be replaced, which is accompanied by the removal of the cylinder head and is almost equivalent to a major overhaul. Note that during engine operation, oil (especially fake) can evaporate and burn out, and a small part of it can enter the combustion chamber and ignite along with gasoline, which is considered normal. And although ideally there should be no oil consumption, its waste in the amount of 200-300 grams per 1000 km is allowed. However, many users on the forums note that consumption up to 0.5 liters per 1000 km can be considered normal. In rare cases, the oil consumption is extremely high - 1 liter per 1000 km, but this requires a quick solution.

- Uncertain start of the engine in a hot state - failure or clogging of the nozzles. The problem is solved by cleaning them or replacing them completely.

One of the problems with the engine is the chain drive. Thanks to him, the motor, although it lasts longer, but a break or jump in the timing drive links will definitely bend the valves. Therefore, it is necessary to replace the chain strictly in accordance with the recommended timing - every 100 thousand kilometers.

In reviews and on forums, owners of cars with QG18DE engines speak positively about these power plants. These are reliable units that, with proper maintenance and rare repairs, “live” for a very long time. But problems with KXX gaskets on cars before 2002 of release take place, as well as problems with floating idle and uncertain start (when the car does not start well).

A characteristic nuisance of the model is the KXX gasket - for many car owners, over time, antifreeze begins to flow to the engine control unit, which can end badly, so from time to time it is necessary to control the level of coolant in the tank, especially if there is floating idle.

Watch this video on YouTube

The last minor problem is the location of the engine number - it is knocked out on a special platform, which is located on the right side of the cylinder block. This place can rust to such an extent that it will not be possible to make out the number.

Tuning

The motors supplied to Europe and the CIS countries are a little clamped by the norms of environmental standards. Because of them, the manufacturer had to sacrifice power to improve the quality of exhaust gases. Therefore, the first solution to increase power is to knock out the catalyst and update the firmware. This solution will increase power from 116 to 128 hp. With. This can be done at any service station where the required software versions are available.

In general, a firmware update will be required when there is a physical change in the design of the motor, exhaust or fuel system. Mechanical tuning without updating the firmware is also possible:

- Grinding cylinder head channels.

- The use of lightweight valves or an increase in their diameter.

- Exhaust tract improvement - you can replace the standard exhaust with a straight-through exhaust using a 4-2-1 spider.

All these changes will increase power to 145 hp. s., but even this is not the top. The potential of the motor is higher, and supercharged tuning is used to open it:

- Installation of special high-performance nozzles.

- The increase in the opening of the exhaust tract up to 63 mm.

- Replacing the fuel pump with a more powerful one.

- Installation of a special forged piston group for a compression ratio of 8 units.

Turbocharging the engine will increase its power by 200 hp. with., but the operational resource will fall, and it will cost a lot.

Conclusion

The QG18DE is an excellent Japanese motor that boasts simplicity, reliability and low maintenance. There are no complex technologies that increase the cost. Despite this, it is durable (if it does not eat oil, then it works for a very long time) and economical - with a good fuel system, high quality gasoline and a moderate driving style, consumption in the city will be 8 liters per 100 km. And with timely maintenance, the motor resource will exceed 400 km, which is an unattainable result even for many modern engines.

However, the motor is not without design flaws and typical “sores”, but all of them are easily solved and rarely require large financial investments.