PSA engine - Ford 1,6 HDi / TDCi 8V (DV6)

In the second half of 2010, the PSA / Ford Group launched a significantly redesigned 1,6 HDi / TDCi engine on the market. Compared to its predecessor, it contains up to 50% recycled parts. Compliance with the Euro 5 emission standard for this engine is taken for granted.

Soon after its introduction on the market, the original unit became very popular due to its performance characteristics. This provided the car with sufficient dynamics, minimal turbo effect, very favorable fuel consumption, high handling and, just as important, due to the favorable weight, also less influence of the engine on the car's driving characteristics. The widespread use of this engine in various vehicles also testifies to its great popularity. It is found, for example, in Ford Focus, Fiesta, C-Max, Peugeot 207, 307, 308, 407, Citroën C3, C4, C5, Mazda 3 and even premium Volvo S40 / V50. Despite the mentioned advantages, the engine has its "flies", which are largely eliminated by the modernized generation.

The basic engine design has undergone two major changes. The first is the transition from a 16-valve DOHC distribution to an 8-valve OHC "only" distribution. With fewer valve holes, this head also has higher strength with less weight. The water channel in the upper part of the block is connected to the cooling head by small asymmetrically located transitions. In addition to lower production costs and greater strength, this reduced design is also suitable for swirling and subsequent combustion of an ignitable mixture. The so-called symmetrical filling of the cylinders has reduced the unwanted swirling of the combustible mixture by 10 percent, thus less contact with the chamber walls and thus almost 10% less heat loss on the cylinder walls. This reduction in swirl is somewhat of a paradox, since until recently swirl was deliberately caused by closing one of the suction channels, the so-called swirl flaps, due to better mixing and subsequent combustion of the ignition mixture. However, today the situation is different, as the injectors deliver diesel fuel at a higher pressure with more holes, so there is no need to help it atomize quickly by swirling the air. As already mentioned, increased air swirl entails, in addition to cooling the compressed air at the cylinder walls, also higher pumping losses (due to the smaller cross section) and slower burning of the combustible mixture.

The second major design change is the modification of the internal cast iron cylinder block, which is housed in an aluminum block. While the bottom is still firmly embedded in the aluminum block, the top is open. In this way, the individual cylinders overlap and create so-called wet inserts (open deck block). Thus, the cooling of this part is directly connected to the cooling channel in the cylinder head, which results in a significantly more efficient cooling of the combustion space. The original engine had cast iron inserts completely cast directly into the cylinder block (closed platform).

Other engine parts have also been changed. The new head, intake manifold, different injector angle and piston shape caused a different ignition mixture flow and hence the combustion process. The injectors were also replaced, which received one additional hole (now 7), as well as the compression ratio, which was reduced from the original 18: 1 to 16,0: 1. By reducing the compression ratio, the manufacturer achieved lower combustion temperatures, of course, for due to exhaust gas recirculation, which leads to a reduction in emissions of hardly decomposable nitrogen oxides. The EGR control has also been changed to reduce emissions and is now more accurate. The EGR valve is connected to the water cooler. The volume of recirculated flue gases and their cooling are controlled electromagnetically. Its opening and speed are regulated by the control unit. The crank mechanism has also undergone a reduction in weight and friction: the connecting rods are cast in parts and split apart. The piston has a simple bottom oil jet without a swirl channel. The larger bore at the bottom of the piston, as well as the height of the combustion chamber, contribute to a lower compression ratio. For this reason, recesses for valves are excluded. The crankcase ventilation is carried out through the upper part of the holder-cover of the timing drive. The aluminum block of cylinders is divided along the axis of the crankshaft. The lower frame of the crankcase is also made of light alloy. A tin oil pan is screwed to it. The removable water pump also contributes to reduced mechanical resistance and faster engine warm-up after starting. Thus, the pump operates in two modes, connected or not connected, while it is driven by a movable pulley, which is controlled according to the instructions of the control unit. If necessary, this pulley is extended to create a friction transmission with a belt. These modifications affected both versions (68 and 82 kW), which differ from each other with a VGT turbocharger (82 kW) - overboost function and different injection. For fun, Ford didn't use glue for the removable water pump and left the water pump directly connected to the V-belt. It should also be added that the water pump has a plastic impeller.

The weaker version uses a Bosch system with solenoid injectors and an injection pressure of 1600 bar. The more powerful version includes Continental with piezoelectric injectors operating at 1700 bar injection pressure. The injectors perform up to two pilot and one main injection while driving in each cycle, the other two during the regeneration of the FAP filter. In the case of injection equipment, it is also interesting to protect the environment. In addition to the low levels of pollutants in the exhaust gases, the Euro 5 emission standard requires the manufacturer to guarantee the required emission level up to 160 kilometers. With a weaker engine, this assumption is fulfilled even without additional electronics, since the consumption and wear of the injection system is less due to the lower power and the lower injection pressure. In the case of the more powerful variant, the Continental system would already have to be equipped with so-called auto-adaptive electronics, which detect deviations from the required combustion parameters while driving and then make adjustments. The system is calibrated under engine braking, when there is an almost imperceptible increase in speed. The electronics then figure out how fast those speeds increased and how much fuel was needed. For correct auto-calibration, it is necessary to transport the vehicle from time to time, for example, down a slope, so that there is a longer engine braking. Otherwise, if this process does not take place within the time specified by the manufacturer, the electronics may display an error message and a visit to the service center will be required.

Today, the ecology of car operation is extremely important, so even in the case of the upgraded 1,6 HDi, the manufacturer left nothing to chance. More than 12 years ago, the PSA group introduced a particulate filter for its flagship Peugeot 607, with special additives to help eliminate particulate matter. The group is the only one who has kept this system to this day, i.e. adding fuel to the tank before the actual combustion. Gradually additives were made based on rhodium and cerium, today similar results are achieved with cheaper iron oxides. This type of flue gas cleaning was also used for some time by the sister Ford, but only with Euro 1,6 compliant 2,0 and 4 liter engines. This particulate removal system operates in two modes. The first is an easier route, i.e. when the engine is working with a higher load (for example, when driving fast on the highway). Then there is no need to transport the unburned diesel injected into the cylinder to the filter where it could condense and dilute the oil. The carbon black formed during the combustion of a naphtha-rich additive is capable of igniting even at 450 ° C. Under these conditions, it is enough to delay the last injection phase, the fuel (even with soot) burns directly in the cylinder and does not jeopardize the oil filling due to the dilution-condensation of diesel fuel in the DPF (FAP) filter. The second option is the so-called assisted regeneration, in which, at the end of the exhaust stroke, diesel fuel is injected into the flue gases through the exhaust pipe. The flue gases carry the pulverized diesel fuel to the oxidation catalyst. The diesel ignites in it and subsequently the soot deposited in the filter burns out. Of course, everything is monitored by the control electronics, which calculates the degree of filter clogging in accordance with the load on the engine. The ECU monitors the injection inputs and uses information from the oxygen sensor and temperature/differential pressure sensor as feedback. Based on the data, the ECU determines the actual condition of the filter and, if necessary, reports the need for a service visit.

Unlike PSA, Ford is taking a different and easier path. It does not use a fuel additive to remove particulate matter. Regeneration occurs as in most other vehicles. This means, firstly, preheating the filter to 450 ° C by increasing engine load and changing the timing of the last injection. Thereafter, the naphtha fed to the oxidation catalyst in an unburned state is ignited.

There were a number of other changes to the engine. For example. The fuel filter has been completely replaced with a metal housing bolted to the top where the hand pump, breather and excess water sensor are located. The basic 68 kW version does not contain a dual-mass flywheel, but a classic fixed flywheel with a spring-loaded clutch disc. The speed sensor (Hall sensor) is located on the timing pulley. The gear has 22 + 2 teeth and the sensor is bipolar to detect the reverse rotation of the shaft after turning off the engine and bringing one of the pistons into the compression phase. This function is required to quickly restart the stop-start system. The injection pump is driven by the timing belt. In the case of the 68 kW version, the Bosch CP 4.1 single-piston type is used with an integrated feed pump. The maximum injection pressure has been reduced from 1700 bar to 1600 bar. The camshaft is installed in the valve cover. The vacuum pump is driven by the camshaft, which creates a vacuum for the brake booster, as well as for controlling the turbocharger and the bypass of the exhaust gas recirculation system. The pressurized fuel tank is equipped with a pressure sensor at the right end. At his signal, the control unit regulates the pressure by adjusting the pump and overflowing the nozzles. The advantage of this solution is the absence of a separate pressure regulator. The change is also the absence of an intake manifold, while the plastic line opens directly into the throttle and is mounted directly on the inlet to the head. The plastic housing on the left contains an electronically controlled cooling bypass valve. In the event of a malfunction, it is completely replaced. The smaller size of the turbocharger has improved its response time and achieved high speeds while its bearings are water cooled. In the 68 kW version, regulation is provided by a simple bypass, in the case of a more powerful version, regulation is provided by a variable geometry of the stator blades. The oil filter is built into the water heat exchanger, only the paper insert has been replaced. The head gasket has several layers of composite and sheet metal. Notches on the top edge indicate the type and thickness used. The butterfly valve is used to suck part of the flue gases from the EGR circuit at very low speeds. It also uses the DPF during regeneration and shuts off the air supply to reduce vibration when the engine is off.

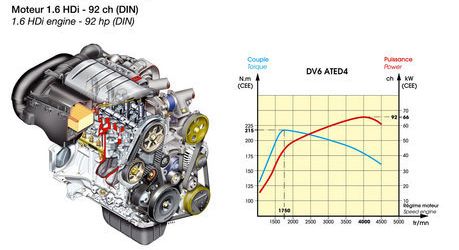

Finally, the technical parameters of the described engines.

The more powerful version of the 1560 cc diesel four-cylinder engine delivers a maximum torque of 270 Nm (previously 250 Nm) at 1750 rpm. Even at 1500 rpm, it reaches 242 Nm. The maximum power of 82 kW (80 kW) is reached at 3600 rpm. The weaker version achieves a maximum torque of 230 Nm (215 Nm) at 1750 rpm and a maximum power of 68 kW (66 kW) at 4000 rpm.

Ford and Volvo are reporting 70 and 85 kW power ratings for their vehicles. Despite the slight differences in performance, the engines are identical, the only difference being the use of an additive-free DPF in the case of Ford and Volvo.

* As practice has shown, the engine is really more reliable than its predecessor. The nozzles are better attached and there is practically no purge, the turbocharger also has a longer life and much less carob formation. However, an irregularly shaped oil pan remains, which under normal conditions (classic replacement) does not allow for a high-quality oil change. Carbon deposits and other contaminants deposited on the bottom of the cartridge subsequently contaminate the new oil, which negatively affects the life of the engine and its components. The engine requires more frequent and costly maintenance to increase its life. When buying a used car, it would be a good idea to disassemble and thoroughly clean the oil pan. Subsequently, when changing the oil, it is recommended to flush the engine with fresh oil, respectively. and remove and clean the oil pan at least every 100 km.