Renault 2,0 dCi engine - M9R - Car seat

Frequently failing turbines, frequent problems with the injection system, valve timing failures, burnt exhaust gas recirculation valves ... When Renault realized that its 1,9 dCi (F9Q) turbo diesel engines were not a real nut, and frequent failures spoiled the name of the automaker, he decided to develop what was primarily a new, more reliable and durable engine. Workshops Renault, in collaboration with Nissan, joined forces, and the new unit, promising durability, was not long in coming. Did he really succeed? So far, experience has shown that it is.

Frequently failing turbines, frequent problems with the injection system, valve timing failures, burnt exhaust gas recirculation valves ... When Renault realized that its 1,9 dCi (F9Q) turbo diesel engines were not a real nut, and frequent failures spoiled the name of the automaker, he decided to develop what was primarily a new, more reliable and durable engine. Workshops Renault, in collaboration with Nissan, joined forces, and the new unit, promising durability, was not long in coming. Did he really succeed? So far, experience has shown that it is.

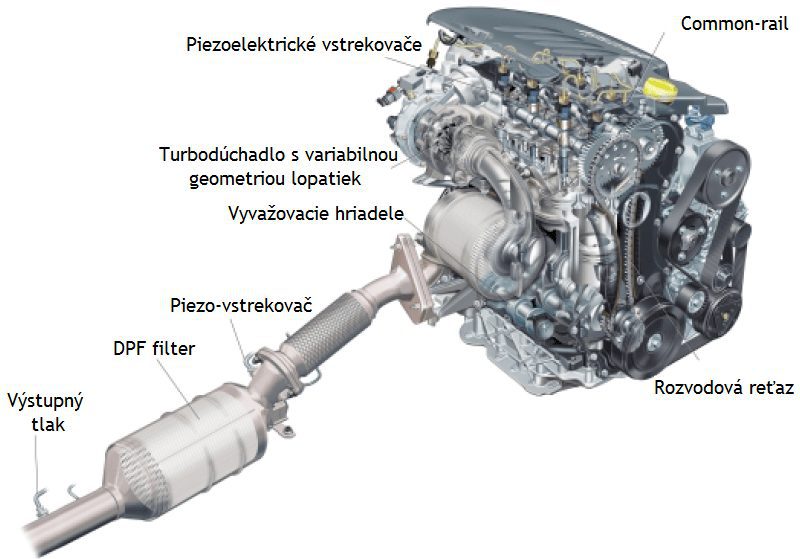

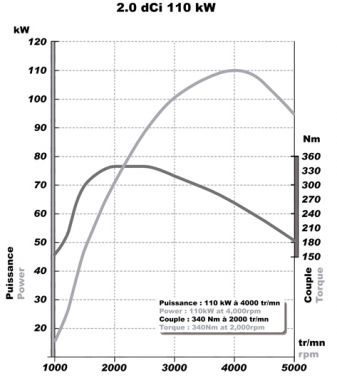

It was 2006 and the 2,0 dCi (M9R) engine entered the market. The second generation Renault Megane and Laguna was the one in which the new unit settled. First there was a 110 kW version to choose from, later 96 kW, 127 kW were added and the latest version stopped at 131 kW. The 4 kW power unit complies with the Euro 4 standard, while the more powerful alternatives did not fit into the Euro XNUMX standard without the installation of a particulate filter. However, this ecological "pendant" certainly will not dissuade lovers of fast and agile driving from buying, as evidenced by the sales of the inflated version of the Megane RS.

engine

The robust cast iron monoblock with 84 mm bore and 90 mm stroke guarantees the reliability and durability of the engine in the combustion chamber. The cast iron block is split exactly along the axis of the crankshaft, which is mounted on sliding surfaces in five places. There is a small hole in the upper part of the main bearing, which serves to better evacuate gases acting on the engine during its operation. Of course, the main combustion chambers must also be well cooled as they are the most thermally stressed part of the engine. The combustion chamber is cooled through a lubrication channel that runs along the entire circumference of the piston, into which the pump injects oil through a nozzle.

No special material was used in the oil bath either. There was no need to attach anything to it, so it is not a pivot or anchor point. The classic oil pan, made of stamped sheet metal, forms the bottom of the entire engine and probably needs no further comment. It's proven, efficient, and cheaper to manufacture. Only when light aluminum alloy crankcase load is required. First of all, of course, it performs the function of strengthening the body itself, and also serves to soundproof the engine. However, the frame itself also functions as two counter-rotating balance shafts driven by gears directly from the crank. These shafts are designed to eliminate any unwanted vibration from the engine.

1,9 dCi engines usually suffered from poor lubrication due to the oil filter being too small for such a large engine. A small roller, quite sufficient for a motorcycle, is not enough to lubricate such a demanding engine, even with an extended service interval (the manufacturer claims 30 km). It's just unthinkable. The "filter" is small, quickly clogged with coal and loses its filtering ability, so its permeability also decreases, which eventually affects the service life - wear and tear of many disposable filters.

And so Renault came up with an innovation that other automakers have been using for a long time. The small ineffective filter has been replaced with a brand new larger filter. The old classic sheet metal filter has been completely replaced. The light alloy filter holder now protrudes from the cylinder block, into which only the paper insert is inserted, which is always replaced with a new one at the next oil change. The same system as we, for example, from engines from VW. This is a cleaner and cheaper solution for both car manufacturers and, ultimately, garages and consumers. The oil cooler, the so-called oil-water heat exchanger, is also attached to the oil filter holder.

Divorce

The classic timing belt has also been replaced with a timing chain belt in the case of the M9R engine. This system is not only much more durable and more durable, but also requires virtually no maintenance and therefore more reliable. The single-row roller timing chain is tensioned hydraulically by a hydraulic roller by means of two sliding tension rods, as we already know from, for example, distribution 1,2 HTP. The tensioner is driven by a camshaft located on the exhaust side, as this engine does not have a separate camshaft for exhaust and separate for intake valves, but both types of valves are driven alternately by each shaft. Since the engine has 16 valves, each valve controls four intake and four exhaust valves per converter. The valves are hydraulically adjusted using single-acting rocker arms to ensure long-term trouble-free operation, subject to regular maintenance intervals. Here, too, the rule applies: the higher the quality of the oil, the longer its service life. The camshafts are driven by a friction transmission, i.e. gear with backlash limiter. We already know everything from previous models of competing cars, but one thing is slightly different. The aluminum alloy on the cylinder head is still nothing special. Nowadays, almost everyone uses it, but in the event of a diesel leak from the high pressure pump, the diesel is trapped in the tank and then drained into the drain pipe. The rest of the cylinder head consists of two parts. Its upper part is formed by the valve cover, the task of which is to ensure maximum tightness of the lubricating space of the valves and, at the same time, their reference point as a plain bearing, thus determining their play. A so-called oil separator is located in the upper part of the valve cover. Spilled oil is collected in this separator, from where it is directed to a pair of pre-separators (pre-separators), where it enters the main separator, which has a built-in control valve that is responsible for all oil separation. process. When the maximum level of the separated oil is reached, the oil is simply drained back to the main circuit through two pipes. The tubes are immersed in suction siphons. This entire space is filled with oil to prevent unwanted gas accumulation from the cylinder block.

Turbocharger

Like any modern diesel engine, the 2,0 dCi (M9R) is turbocharged. Renault has made changes here too, and quite extensive ones. The all-new turbocharger is now water-cooled (until now we've only seen this system with petrol engines) directly from the water circuit of the engine cooling block, ensuring a stable temperature throughout the entire trip. After a long drive on the highway, it is no longer necessary to leave the car idling for a while (approximately 1-2 minutes) and wait for the hot turbocharger to cool down a bit. This eliminates the risk of damage to bearings that can stick to soot when the turbo is hot and not cooled. The automaker has replaced the relatively brittle and rotting turbo from previous 1,9 dCi diesel engines with a more powerful turbo. The "lightweights" of the new turbocharger are variable vanes controlled by the control unit, capable of regulating filling pressure more efficiently and in almost any speed range.

Injection

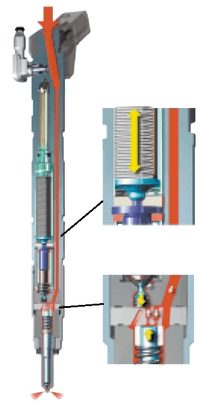

The common rail injection system, in which Renault uses the latest generation EDC 16 CP33 from Bosch, has also been modified. A new feed pump for the new CP3 fuel pump has been found in the fuel tank. The system has remained almost identical, only the new pump injects on the principle of suction, and not high pressure injection, as it was in the old system. The fuel flow control unit indicates to what extent and to what extent the injector should be opened and how much fuel should be supplied from the tank by the feed pump. In addition, injection is provided by regulating the pressure in the injection rail. Immediately after starting, there will simply be not a full refueling dose in the strip, but only a partial one, so that the engine can remember immediately after starting and gradually warm up. The rail pressure control is also used when the accelerator pedal is released abruptly while driving, so there is no overpressure effect. It's just that when you release the pedal, the car doesn't jerk. Reburning of the exhaust gases is ensured by a cooled exhaust gas recirculation valve, which is controlled by an electric motor and not pneumatically (vacuum). Thus, the EGR valve can change its position even if the situation does not require it. This movement ensures that the valve is not clogged with exhaust fumes and engine oil lubrication.

The common rail injection system, in which Renault uses the latest generation EDC 16 CP33 from Bosch, has also been modified. A new feed pump for the new CP3 fuel pump has been found in the fuel tank. The system has remained almost identical, only the new pump injects on the principle of suction, and not high pressure injection, as it was in the old system. The fuel flow control unit indicates to what extent and to what extent the injector should be opened and how much fuel should be supplied from the tank by the feed pump. In addition, injection is provided by regulating the pressure in the injection rail. Immediately after starting, there will simply be not a full refueling dose in the strip, but only a partial one, so that the engine can remember immediately after starting and gradually warm up. The rail pressure control is also used when the accelerator pedal is released abruptly while driving, so there is no overpressure effect. It's just that when you release the pedal, the car doesn't jerk. Reburning of the exhaust gases is ensured by a cooled exhaust gas recirculation valve, which is controlled by an electric motor and not pneumatically (vacuum). Thus, the EGR valve can change its position even if the situation does not require it. This movement ensures that the valve is not clogged with exhaust fumes and engine oil lubrication.

The solenoid injectors have been redesigned and replaced with new piezoelectric injectors, which are much more reliable than the solenoid injectors, which can reach a higher boost pressure, which stalled up to 1600 bar, after which the fuel is even thinner. sprayed into the combustion chamber. In one piston stroke, the injector rapidly atomizes fuel five times. The manufacturer stated that this is mainly due to an attempt to reduce the external noise of the entire diesel unit.

Renault has always strived to produce so-called eco-friendly models. Therefore, in the production and development of new cars, he always thought about the nature and conservation of non-renewable resources. An automatic diesel particulate filter with regular regeneration every 500-1000 km, depending on filter clogging, also takes care of reducing emissions. If the engine control unit detects that the pressure upstream and downstream of the particulate filter is not the same, the combustion process begins immediately, which lasts about 15 minutes, depending on the degree of clogging of the filter. During this process, fuel is injected into the filter by a piezoelectric injector, raising the temperature to about 600 ° C. If you frequently drive around town, then we recommend that you run your car on the highway at higher speeds from time to time for at least 20 minutes. The engine will only benefit after a long run around the city.

Practical Experience: Time has shown that while this engine features a rugged cast iron construction and the aforementioned maintenance-free chain and water-cooled turbocharger, it was not as reliable. It can sometimes be surprising with a cracked seal under the cylinder head, there has also been an oil pump failure and there have also been known cases of crankshaft seizures in which the connecting rod bearings are undersized (modified in 2010) but generally over-optimistic oil change intervals. - 30 thousand km, which are recommended to be reduced to max. 15 km.

Transmission of infection

The 2,0 dCi (M9R) series engines are combined with a lighter light alloy gearbox to deliver up to 360 Nm of torque. Six gears and three shafts suggest that the mechanism itself is descended from a previous version, codenamed PK6.

The heavier the car model used this old transmission, the more faulty it was. Transmission shaft bearing repair, often the gear timing issue mentioned on the forums, may be a thing of the past and we can only firmly believe that the new Renault Workshop Retrofit (PK4) transmission has completely eliminated the above issues.