Variable Compression Engine / Variable Compression Engine Operation

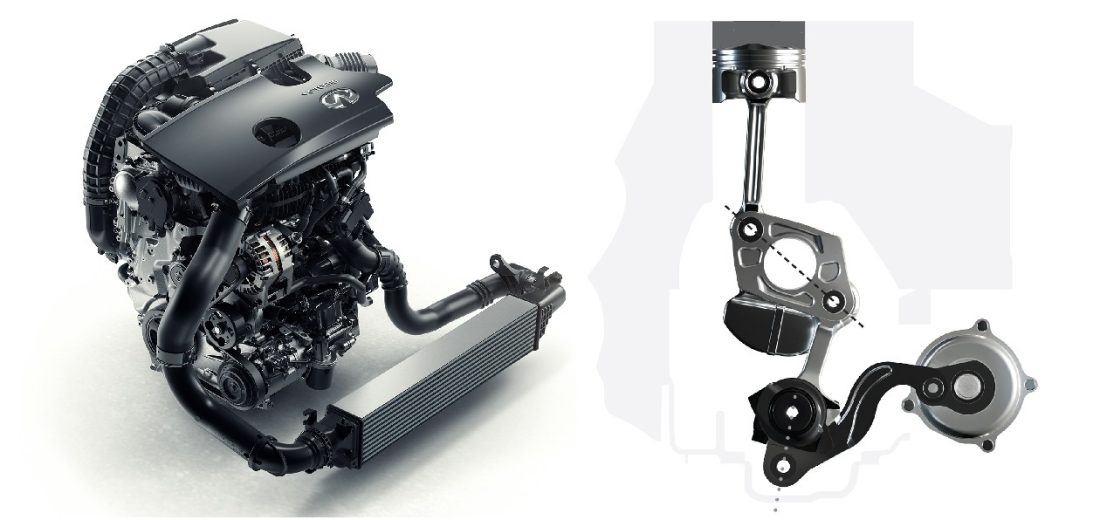

Introduced by Infiniti, but long considered by many other manufacturers, the variable compression engine is now available in the automotive market.

Compression?

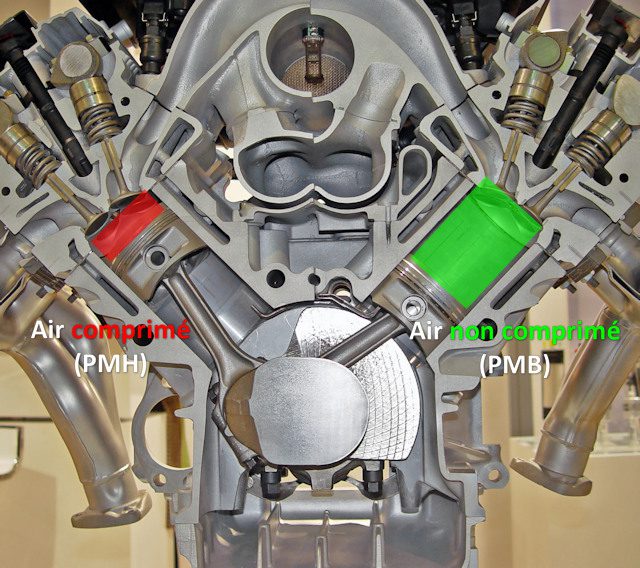

First of all, it is important to know what the compression ratio of the engine is. This is a fairly simple relationship between the volume of air uncompressed (when the piston is at the bottom: bottom dead center) and when it is compressed (when the piston is at the top: top dead center). This speed does not change, because the position of the piston at the bottom or top always remains the same, so the roundabouts go from point A (PMB) to point B (PMH).

On this classic V-engine, we see TDC and PMA at the same time. Compressed air on the left and uncompressed air on the right

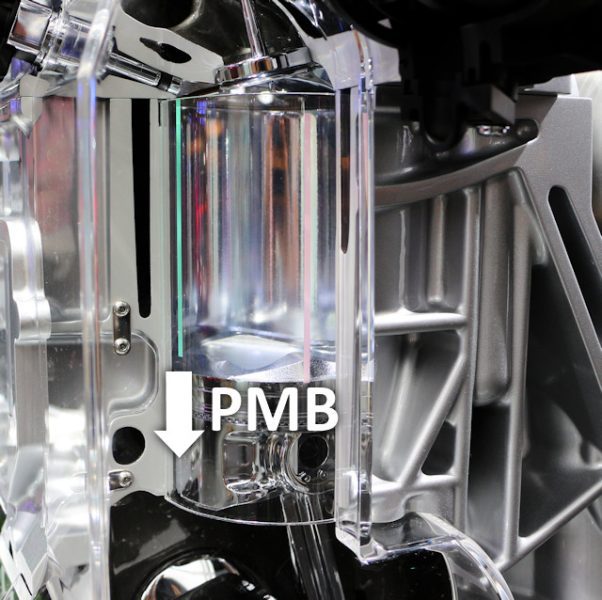

PMB: piston at the bottom

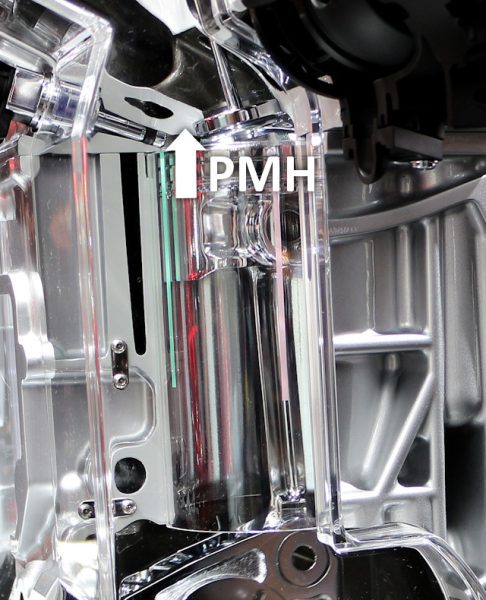

TDC: the piston is at the top

The advantage of a high compression ratio?

Note that the more you increase the compression ratio, the more you increase the efficiency of the engine, so it becomes less power hungry. Therefore, the goal of the designers is to raise it as high as possible. However, it is logical that the greater the pressure, the greater the load on the mechanical elements, so care should be taken not to overdo it. In addition, compressing a gas increases its temperature, which is the physical principle behind diesel engines. At a certain stage, if we compress the gasoline too much in the gas (hence air), the temperature will be so high that the gasoline will burn on its own even before the candle ignites it... Then the ignition will happen too soon, causing damage to the cylinders (but also valves) and cause knocking.

The knock phenomenon will intensify with a large amount of fuel, that is, when loading (the more you press the pedal, the more fuel is injected).

In such a case, the ideal would be to have a high compression ratio at low load and a ratio that "calms down" a little when pressed hard.

Variable Compression Ratio: But How?

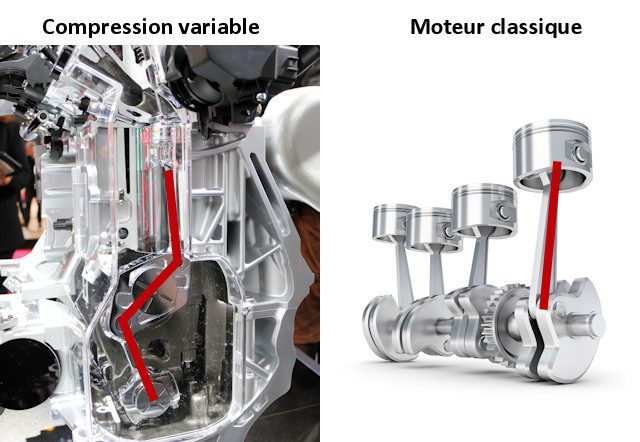

Knowing that the compression ratio depends on the height at which the piston can move (TDC), then it is enough to be able to change the length of the connecting rods (these are the “rods” that hold the pistons and connect them to the crankshaft). The system, invented by Infiniti, therefore changes this height thanks to the electromagnetic system, so the cranks can now be extended! The two possible ratios are then changed from 8: 1 to 14: 1, after which the gas / fuel mixture can be compressed up to 8 or 14 times, making a great difference!

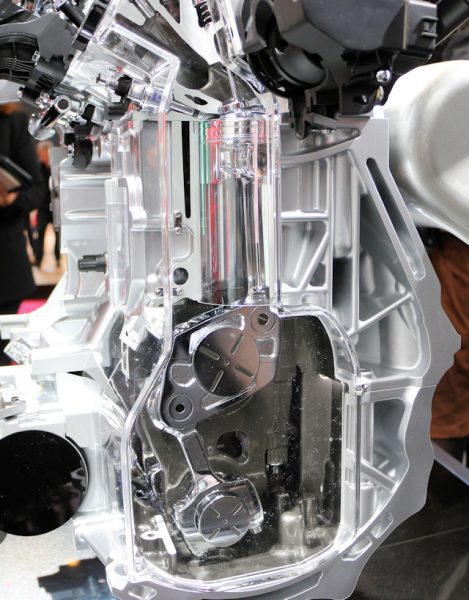

We are talking about a movable crankshaft, connoisseurs will quickly notice that it does not look like what we are used to seeing.

This is in contrast to a conventional engine, whose connecting rods are simple rods connected to the crankshaft.

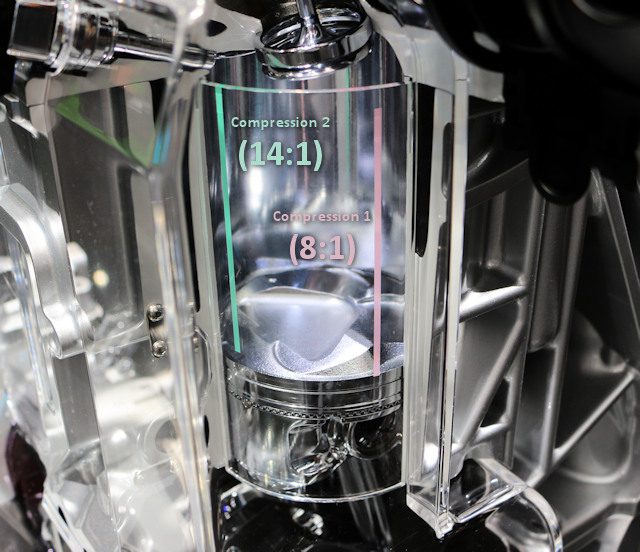

Here are two labels that Infiniti has designated to represent the two possible TDCs.

At low load, the ratio will be at its maximum, that is, 14: 1, while at high load it will drop to 8: 1 to avoid spontaneous combustion before the spark plug has done its job. So we should expect to see savings when you have a light foot, sporty driving ultimately does not change as the compression becomes "normal" again. It remains to be seen if this type of moving crank will be reliable in the long run, because adding moving parts is always risky ...

All comments and reactions

Dernier comment posted:

piano (Date: 2019, 10:03:20)

Here is a precise and clear explanation of the promising technology. To be continued, thanks.

Il I. 1 reaction (s) to this comment:

- Administrator SITE ADMINISTRATOR (2019-10-06 15:24:45): Thank you very much, however the future seems to leave the heat ...

(Your post will be visible under the comment after verification)

Extension 2 Comments :

Lili (Date: 2017, 05:30:18) |

Hi, Thanks for all your articles which are very well explained and taught me a lot. If I understand correctly, gasoline engines are now equipped with direct injection, just like diesels. So why do we continue to "control" the compression ratio to prevent self-ignition when the compressed air contains no fuel? Il I. 5 reaction (s) to this comment:

(Your post will be visible under the comment) |

Write a comment

What do you think of traffic light radars?