Engine VAZ-4132

Content

AvtoVAZ engineers created a special power unit, which many people still do not know about. It was intended for installation on cars of the USSR special services (KGB, Ministry of Internal Affairs and GAI).

The principle of operation, as well as the mechanical part, was fundamentally different from the usual in-line or V-shaped piston engines.

Description

The history of the birth of a fundamentally new motor began in 1974. After two years (in 1976), the first version of a domestically developed rotary piston engine was born. It was far from perfect and did not go into mass production.

And only by 1986 the unit was finalized and put into production according to the factory index VAZ-4132. The engine did not receive wide distribution, since domestic law enforcement agencies began to use the created unit to equip their special vehicles.

Since 1986, the engine has been installed on VAZ 21059 operational vehicles, and since 1991 it has received a residence permit under the hood of VAZ 21079. The engine provided the maximum speed of cars up to 180 km / h, while acceleration to 100 km / h took only 9 seconds.

VAZ-4132 is a 1,3-liter gasoline rotary engine with a capacity of 140 hp. with and a torque of 186 Nm.

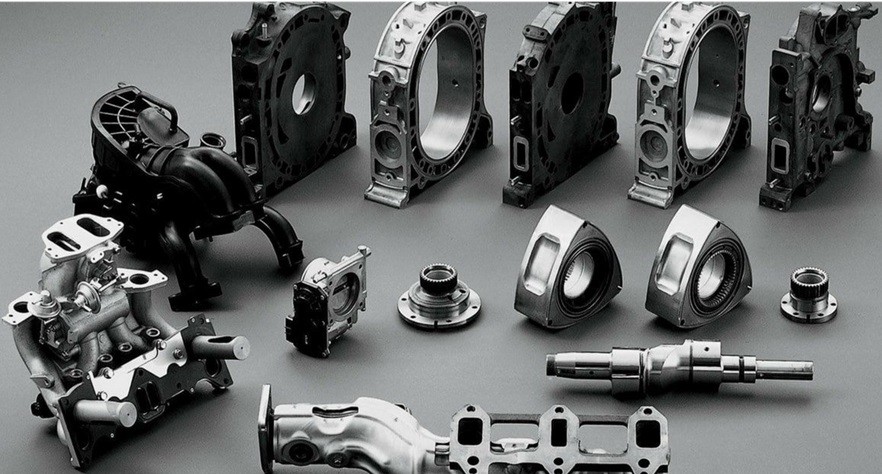

The device and principle of operation of a rotary engine are fundamentally different from the well-known piston units.

Instead of cylinders, there is a special chamber (section) in which the rotor rotates. All strokes (intake, compression, stroke and exhaust) occur in its different parts. There is no conventional timing mechanism. Its role is performed by inlet and outlet windows. In fact, the role of the rotor is reduced to their alternate closing and opening.

During rotation, the rotor forms three cavities isolated from each other. This is facilitated by the special shape of the section formed by the rotor and part of the chamber. In the first cavity, the working mixture is formed, in the second, it is compressed and ignited, and in the third, exhaust gases are released.

The engine device is more unusual than complex.

You can learn more about the design of the motor and the principle of its operation by watching the video:

Benefits of a rotary motor:

- High performance. Without delving deeply into the theory, a two-chamber rotary internal combustion engine with the same working volume is adequate to a six-cylinder piston.

- The minimum number of components and parts on the engine. Based on the statistics, they are 1000 units less than on the piston.

- Virtually no vibration. The circular rotation of the rotor simply does not cause it.

- High dynamic characteristics are provided by the design feature of the motor. Even at low speeds, the internal combustion engine develops high speed. In part, this is due to the fact that three strokes occur in one revolution of the rotor, and not four, as in the usual piston motors.

There are also disadvantages. They will be discussed a little later.

Technical specifications

| Manufacturer | Autoconcern "AvtoVAZ" |

| engine's type | rotary |

| Number of sections | 2 |

| Release year | 1986 |

| Volume, cm³ | 1308 |

| Power, hp from | 140 |

| Torque, Nm | 186 |

| Compression ratio | 9.4 |

| Oil consumption (calculated), % of fuel consumption | 0.7 |

| Fuel system | carburetor |

| Fuel | gasoline AI-92 |

| Environmental standards | Euro 0 |

| Resource, outside. km | 125 |

| Weight, kg | 136 |

| Location | longitudinal |

| Tuning (potential), l. With | 230* |

*without turbine installation

Reliability, weaknesses, maintainability

Reliability

The engine had high reliability with a short mileage resource. It is noted that, on average, he nursed about 30 thousand km on operational vehicles of law enforcement agencies. Further major repairs were required. At the same time, there is evidence that for ordinary motorists, the life of the motor increased to 70-100 thousand km.

The increase in mileage depends on many factors. For example, on the quality of the oil and the timing of its replacement (after 5-6 thousand km).

One of the reliability factors is the possibility of forcing the engine. VAZ-4132 has a good margin of safety. With the right tuning, power can be significantly increased, which is done on racing cars.

For example, up to 230 liters. with no boost. But at the same time, the resource will drop to about 3-5 thousand km.

Thus, having compared many well-known factors about the reliability of the engine, the general conclusion will not be comforting - the VAZ-4132 does not have reliability after 30 thousand kilometers.

Weak spots

VAZ-4132 has a number of significant weaknesses. Their combination was the reason for the removal of the motor from production.

Tendency to overheat. Due to the lenticular geometric shape of the combustion chamber. Its heat dissipation capacity is minimal. When overheated, the rotor is deformed first. In this case, the operation of the engine ends.

High fuel consumption also directly depends on the design of the combustion chamber. Its geometry does not allow vortex filling with the working mixture.

As a result, it does not burn completely. According to the results of the research, only 75% of the fuel burns out in full.

The rotor seals, with their rubbing surfaces, come into contact with the chamber body at constantly changing angles, while experiencing enormous loads.

At the same time, their operation takes place with a limited possibility of lubrication in high-temperature conditions. In order to reduce the load on the seals, oil is injected into the intake manifold.

As a result, the design of the engine becomes somewhat more complicated and at the same time the possibility of exhaust purification to European standards is noticeably reduced.

Low overhaul resource. Although it is indicated by the manufacturer at 125 thousand kilometers, in reality the engine can withstand about 30 thousand kilometers. This is understandable - operational machines do not differ in accuracy of operation.

The highest quality requirements for assembly units make the engine unprofitable for production. The use of high-tech equipment causes a high cost of the engine (both for the manufacturer and for the buyer).

Maintainability

VAZ-4132 is characterized by low maintainability and complexity of repair. According to car owners from Internet forums, not every car service (according to available information, there are only two such service stations - one in Togliatti, the other in Moscow) undertakes engine restoration.

As Alekseich writes:... you open the hood at the service, and the servicemen ask: where is your engine ...". There is a small number of specialists capable of repairing this engine and the high cost of work.

At the same time, there are messages on the forums that the motor can be repaired on its own, but it is necessary to use only sets of components and mechanisms.

In other words, if you need to replace the rotor, then you have to change the entire section assembly. Given the high cost of spare parts, such repairs will not be cheap.

When choosing spare parts, there may be problems with finding them. This is understandable, the motor has never been widely sold. At the same time, there are several online stores that offer parts for this particular engine.

Before restoring the unit, it will not be superfluous to consider the option of purchasing a contract engine. You can find sellers on the Internet, but you immediately need to count on the fact that it will not be cheap (from 100 thousand rubles for a used engine).

The rotary VAZ-4132 is a powerful engine, but has not been used by the masses. The high cost of operation and unsatisfactory maintainability, as well as low mileage and high cost are the factors due to which the internal combustion engine did not cause active demand among a wide range of motorists.