Volkswagen AVU engine

Content

For popular models of the VAG auto concern, a special power unit was created, which was included in the line of Volkswagen engines EA113-1,6 (AEN, AHL, AKL, ALZ, ANA, APF, ARM, BFQ, BGU, BSE, BSF).

Description

In 2000, Volkswagen designers developed and introduced into production a new engine, called the AVU.

Initially, it was designed for operation outside extreme conditions. The idea of engineers - to create a reliable and at the same time powerful engine for a car, which will be driven by a calm and balanced motorist, has come true.

AVU was produced at the production facilities of the Volkswagen concern for two years, until 2002.

Structurally, the unit incorporated a number of innovative solutions. These include a variable geometry intake manifold, an improved valve train, a secondary air system, an electronic thermostat and a number of others.

The Volkswagen AVU engine is a 1,6-liter gasoline in-line four-cylinder aspirated engine with a capacity of 102 hp. with and a torque of 148 Nm.

It was installed on the following models of VAG's own production:

- Audi A3 I /8L_/ (2000-2002);

- Volkswagen Golf IV /1J1/ (2000-2002);

- Golf IV Variant /1J5/ (2000-2002);

- Bora I /1J2/ (2000-2002);

- Bora station wagon /1J6/ (2000-2002);

- Skoda Octavia I /1U_/ (2000-2002).

Aluminum cylinder block with cast iron liners.

The crankshaft is steel, forged. It sits on five pillars.

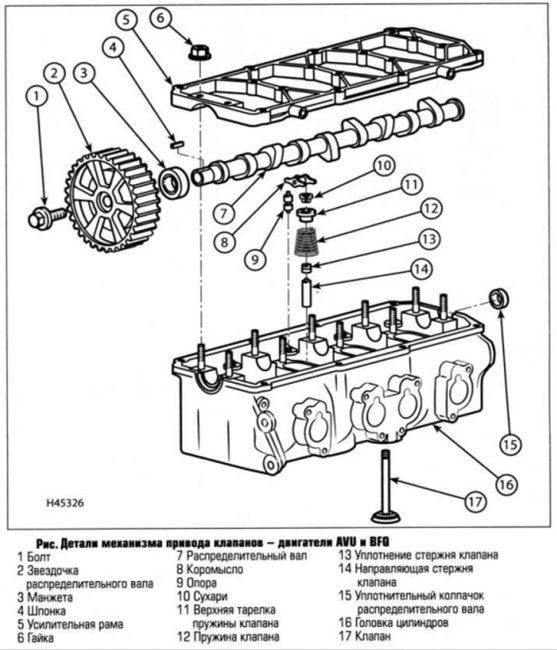

The cylinder head is cast from aluminium. At the top, one camshaft (SOHC) is fixed in a special frame.

Eight valve guides are pressed into the body of the head. The valve mechanism has been modernized - roller rockers are used to actuate them. The thermal gap is regulated by hydraulic compensators.

Timing belt drive. The condition of the belt must be checked every 30 thousand km, since if it breaks, bending of the valves is inevitable.

The lubrication system uses 5W-40 oil with a VW 502 00 or VW 505 00 approval. Gear type oil pump, chain driven from the crankshaft. The capacity of the system is 4,5 liters.

Fuel supply system injector. The system is controlled by the Siemens Simos 3.3A ECM. Throttle actuator electronic. Used candles NGK BKUR6ET10.

A novelty in the cooling system is an electronic thermostat (expensive and capricious!).

A nice feature for motorists was the ability to transfer the engine to gas.

Specialists and car owners note the reliability and durability of the unit with its timely maintenance.

Technical specifications

| Manufacturer | Audi Hungaria Motor Kft., Salzgitter Plant, Puebla Plant |

| Release year | 2000 |

| Volume, cm³ | 1595 |

| Power, hp from | 102 |

| Power index, l. s/1 liter volume | 64 |

| Torque, Nm | 148 |

| Compression ratio | 10.3 |

| Cylinder block | aluminum |

| Number of cylinders | 4 |

| Cylinder head | aluminum |

| The working volume of the combustion chamber, cm³ | 38.71 |

| Fuel injection order | 1-3-4-2 |

| Cylinder diameter, mm | 81 |

| The piston stroke, mm | 77,4 |

| Timing drive | belt |

| Number of valves per cylinder | 2 (SOHC) |

| Turbocharging | no |

| Hydraulic compensators | Yes |

| Camshaft adjuster | no |

| Lubrication system capacity, l | 4.5 |

| Applied oil | 5W-40 |

| Oil consumption (calculated), l / 1000 km | up to 0,5* |

| Fuel system | injector, port injection |

| Fuel | gasoline AI-95 |

| Environmental standards | Euro 3 |

| Resource, outside. km | 350 |

| Start-Stop system | no |

| Location | transverse |

| Tuning (potential), l. With | 115** |

*on a serviceable engine 0,1/1000 km; ** face value after high-quality chip tuning

Reliability, weaknesses, maintainability

Reliability

The resource and margin of safety of AVU are quite impressive. According to reviews, the motor easily takes care of more than 500 thousand km without any serious damage. According to car owners, the engine has practically no characteristic malfunctions.

At the same time, the low quality of gasoline significantly reduces the reliability of the unit.

The margin of safety allows you to force the internal combustion engine more than twice. Fans of such alterations should think about the advisability of intervening in the design of the motor.

It must be remembered that the 1,6-liter eight-valve was created as a regular urban unit, without pretensions to sports. That is why, with serious tuning, you will have to change almost all components and mechanisms of the engine, from the crankshaft to the cylinder head.

In addition to serious material investments and the time spent, the internal combustion engine will be ready for scrapping after 30-40 thousand kilometers.

Weak spots

There are practically no weak points in the internal combustion engine. This does not mean that there are no breakdowns in it. Arise. But for long distances. Due to natural wear and tear. An additional contribution to this problem is made by our low-quality fuels and lubricants.

After 200 thousand km of run, increased oil consumption begins to appear in the engine. In this case, you need to check the condition of the valve stem seals and piston rings. If necessary, replace.

There are errors in the operation of the throttle valve. Most often, the fault is poor contact in the DZ connector (provided that the damper itself is clean and operational).

Unstable speeds appear if there is a crack in the ignition coil or if the fuel pump is clogged.

The only weak point is the bending of the valves when the timing belt breaks.

Over time, the destruction of the plastic elements of the motor occurs.

Seals do not last forever in health systems.

Maintainability

According to numerous reviews of car owners, in addition to reliability, AVU has good maintainability. At the same time, it should be noted that self-repair of the engine is only possible for those who have experience in plumbing work.

ICE can be repaired in a garage. There are no big problems with finding spare parts, but sometimes when purchasing them, significant, at the same time, unnecessary investments are required. Let's look at an example.

Sometimes the actuator rod mount breaks from time to time, the intake manifold length adjustment flaps stop working. In the vast majority of cases, the cause of the breakdown lies in the breakdown of the membrane bracket. The part is not supplied separately.

The craftsmen found a way out. The bracket is easy to make yourself. Simple and not expensive. And you don't have to buy an intake manifold.

Additionally, VAG itself offers to reduce the cost of repairs if possible. For example, make a homemade device for locking the camshaft sprocket when repairing the timing.

You can buy ready-made, but two metal strips and three bolts will become much cheaper.

Some motorists instead of repair choose the option of purchasing a contract engine.

The price of such an internal combustion engine starts from 45 thousand rubles.