Volkswagen BZG engine

Content

The VAG auto concern mastered the production of a new model of a three-cylinder 12-valve engine.

Description

The Volkswagen auto concern launched another internal combustion engine, which received the BZG index. Its release began in 2007. The main purpose of the unit is a complete set of small cars of the concern.

The design was based on the previously created six- and twelve-valve low-volume four-stroke VAG engines.

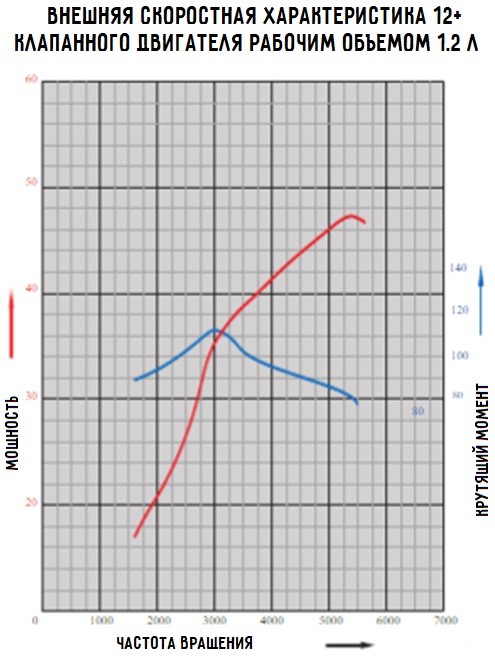

The BZG engine is a 1,2-liter gasoline in-line three-cylinder aspirated engine with a capacity of 70 hp. with and a torque of 112 Nm.

It was installed on Volkswagen Polo V, Skoda Fabia II and Seat Ibiza IV cars.

The cylinder block is cast aluminum. The peculiarity lies in its design of two parts. Cylinder liners are located at the top, crankshaft bearings and a balancing (balancing) mechanism are located at the bottom, designed to dampen second-order inertial forces (reduce vibration levels).

Sleeves are thin-walled. Made from cast iron. The features include their cooling principle: the coolant flow has a horizontal direction. This engineering solution ensures uniform cooling of all three cylinders.

The crankshaft is mounted on four bearings. Main bearings (liners) are steel, thin-walled with an antifriction layer. They are installed at the factory and are not subject to replacement during the repair process.

Aluminum pistons, with three rings, two upper compression, lower oil scraper. Piston pins of floating type, are fixed by lock rings.

The bottoms have a deep groove, but it does not save from meeting the valves in the event of a timing chain jump - bending the valves is inevitable.

Connecting rods are steel, forged, I-section.

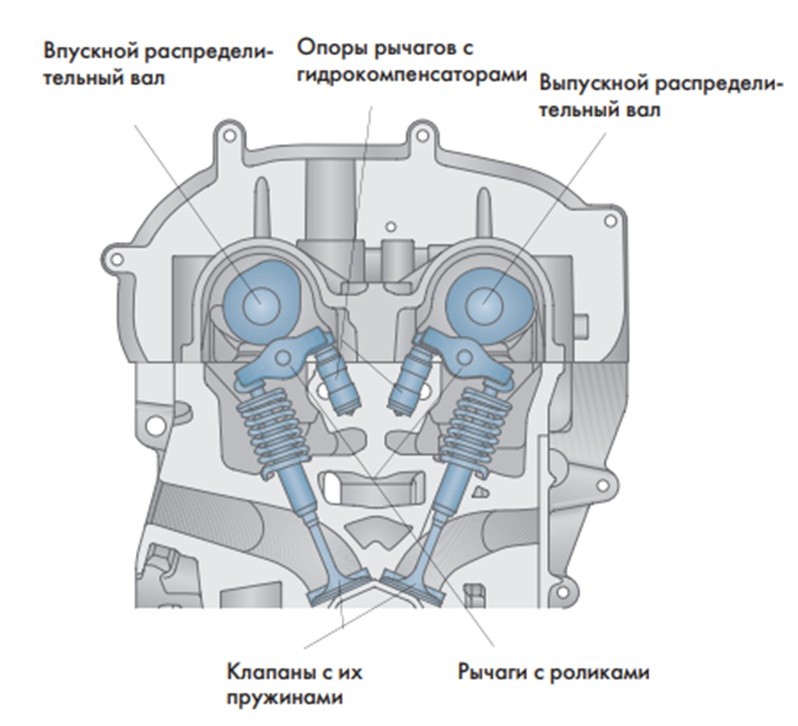

The cylinder head is aluminum, with two camshafts (DOHC) and twelve valves. Adjustment of the thermal gap does not require intervention - hydraulic compensators cope with this work.

Fuel injection system. Includes fuel pump (located in the gas tank), throttle assembly, fuel pressure regulator, injectors and fuel lines. It also includes an air filter.

Combined type lubrication system. The oil pump has its own chain drive. The oil filter is fixed in a vertical position on the side of the exhaust manifold.

Closed cooling system. The peculiarity lies in the horizontal direction of the coolant flow. The water pump (pump) is driven by a V-ribbed belt.

The ignition system is microprocessor. BB coils are individual for each candle. The system is controlled by the Simos 9.1 ECU.

With the existing shortcomings, the BZG as a whole has good external speed characteristics.

Technical specifications

| Manufacturer | car concern VAG |

| Release year | 2007 |

| Volume, cm³ | 1198 |

| Power, hp from | 70 |

| Torque, Nm | 112 |

| Compression ratio | 10.5 |

| Cylinder block | aluminum |

| Number of cylinders | 3 |

| Cylinder head | aluminum |

| Fuel injection order | 1-2-3 |

| Cylinder diameter, mm | 76.5 |

| The piston stroke, mm | 86.9 |

| Timing drive | chain |

| Number of valves per cylinder | 4 (DOHC) |

| Turbocharging | no |

| Hydraulic compensators | Yes |

| Camshaft adjuster | no |

| Swab system capacity, l | 2.8 |

| Applied oil | 5W-30, 5W-40 |

| Oil consumption (calculated), l / 1000 km | 0.5 |

| Fuel system | injector, multipoint fuel injection |

| Fuel | gasoline AI-95 (92) |

| Environmental standards | Euro 4 |

| Resource, outside. km | 200 |

| Location | transverse |

| Tuning (potential), l. With | 81-85 |

Reliability, weaknesses, maintainability

Reliability

The question of the reliability of this unit does not have a general answer. Some car owners consider this motor not powerful enough, and even frankly weak. At the same time, many argue the opposite. Maybe it depends on how you use it.

The reliability of the engine directly depends on careful operation.

Regular operation at high speeds (over 3500 rpm) leads to overheating of the oil, and, as a result, blocking of the hydraulic valve lifters. As a result, the valve seats burn out, and the compression drops.

Here, as a result of the malfunction, it can be argued that the engine is not reliable, “fragile”. This conclusion is not true, since the breakdown is caused by improper operation of the motor.

It is generally accepted that the reliability parameter of an internal combustion engine is characterized by its mileage and safety margin. Everything is fine with the resource. According to reports, with timely maintenance and careful operation, the engine takes care of up to 400 thousand km without much stress.

With questions of safety margin, everything is somewhat more complicated. Given the design (three cylinders), a large degree of forcing the engine is not provided. But by simply flashing the ECU, you can increase the engine power by 10-15 liters, forces.

At the same time, it should be borne in mind that the degree of exhaust purification will decrease to approximately Euro 2. And the additional load on the units of the unit will have a negative impact on their operation. As a result, breakdowns will occur more often, and the mileage resource will be slightly, but certainly reduced.

Weak spots

There are many problem areas in the engine. The biggest problem is the ignition coils. Sometimes they fail after 30 thousand kilometers (the coil of the second cylinder is especially naughty).

As a result of their inadequate operation, the electrodes of the candles are covered with deposits, which in turn adversely affects the operation of the explosive coil. There are misfires (triple). Most often, this picture is observed after repeated being in traffic jams, a long drive at low speeds.

Timing chain jump. The danger of this phenomenon lies in the inevitable meeting of the piston with the valves. In some sources, the chain resource is indicated as 150 thousand km, but in reality it is extended much earlier.

An engineering flaw is the absence of a hydraulic tensioner anti-running stopper. Therefore, the tensioner performs its task only if there is pressure in the lubrication system.

That's why you shouldn't leave your car on a slope in a parking lot in gear or start the engine from a tow.

Experienced car owners advise replacing the chain after 70 thousand km.

Increased sensitivity of injectors and throttle to fuel quality. They tend to get dirty quickly. A basic flush will solve the problem.

Valve burnout. As a rule, this trouble is caused by a clogged catalyst. The reason is again not high-quality fuel. A clogged converter creates back pressure for the exhaust gases passing through it, which in turn creates the conditions for burnt valves.

The remaining weaknesses of the engine rarely appear (failure of the coolant temperature sensor, failure of the crankcase ventilation valve).

The use of high-quality fuels and lubricants and timely maintenance of the motor will help to neutralize the negative problem areas of the unit.

Maintainability

All VAG three-cylinder engines are distinguished by specific maintainability. BZG is no exception.

When repairing the unit, the first difficulties will arise with the selection of spare parts. The market is provided with them, but not by all. For example, there are no crankshaft main bearings for sale. The shaft is mounted at the factory and cannot be repaired. The same situation is with the valve guides.

The cylinder block is aluminum, i.e. not repairable.

Another problem is the high cost of spare parts. On this occasion, Alexannnn-Der from Kaliningrad wrote: “… head repair (burnt valves) … repair budget (with new oil / coolant / work and parts) about 650 euros … That's such crap.».

At the same time, there are cases when the BZG motor was completely overhauled. Spare parts were selected from other engines. StanislavskyBSK from Biysk shares his experience of such a repair: “… I looked for the rear crankshaft oil seal in the catalog, found 95 * 105 … and then it dawns on me !!! This is the Toyota size, on 1G and 5S motors it is used ...».

Before proceeding with the repair of the motor, it is advisable to consider the option of purchasing a contract engine. The cost depends on many parameters: wear, completeness with attachments, mileage, etc. The price ranges from 55 to 98 thousand rubles.

The Volkswagen BZG engine, with timely and high-quality service, refueling with proven fuels and lubricants and reasonable operation, is quite reliable and durable, has a long mileage resource.