Volkswagen CMBA engine

Content

Especially for equipping the Volkswagen Golf of the seventh series, a fundamentally new power unit was developed, which was included in the EA211-TSI line (CHPA, CXSA, CZCA, CZDA, CZEA, DJKA).

Description

The CMBA engine was created in 2012, but a year later it began to be replaced by another model (CXSA). Discontinued in 2014.

The shortened life of the internal combustion engine was facilitated by the problems that appeared during the operation of the motor.

During the development of the unit, the engineers of the VAG concern made miscalculations, as a result of which the CMBA became unsuccessful. Weaknesses will be discussed in more detail below.

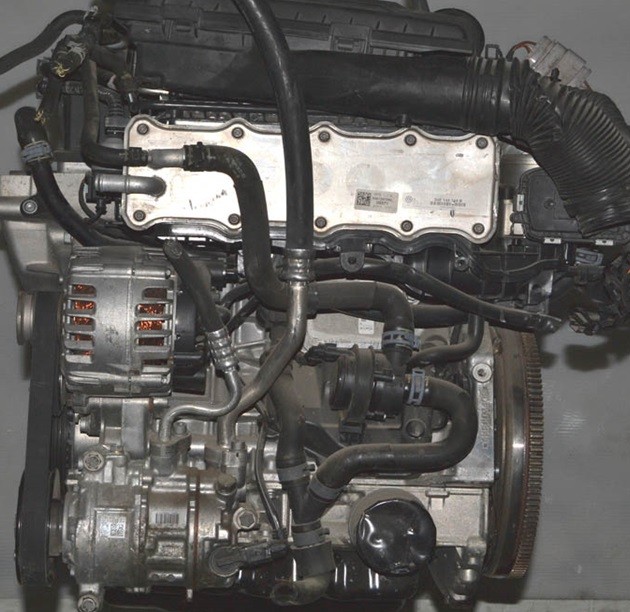

The Volkswagen CMBA ICE is the basic initial modification of the 1.4 TSI EA211 engine. The volume of the engine is 1,4 liters, the power is 122 liters. s at a torque of 200 Nm. Supercharging is carried out by a TD025 M2 turbine (excess pressure 0,8 bar).

This unit was installed on cars of the VAG concern:

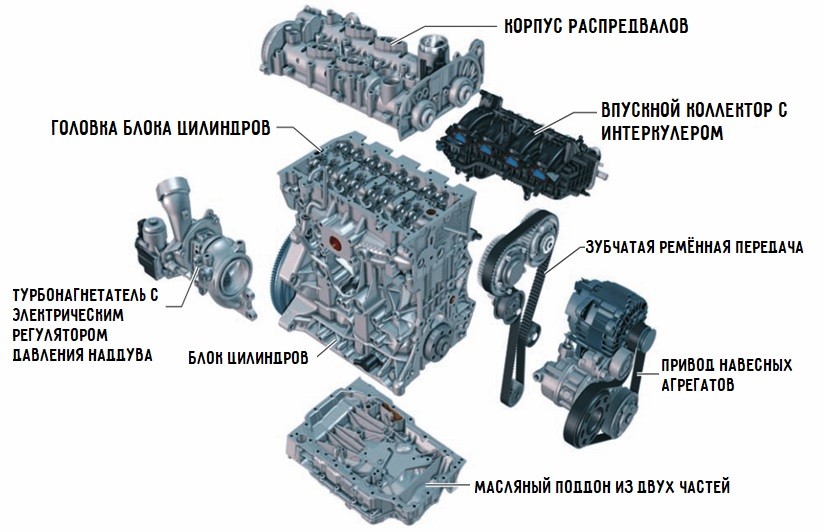

A feature of the unit is its modular design. Such a technical solution along with the "pluses" has a lot of "minuses".

The cylinder block is made of aluminum, the liners are cast iron, thin-walled. Lightweight pistons, crankshaft and connecting rods. Reducing the weight of the internal combustion engine has a positive effect on performance. At the same time, it significantly increases the cost of its repair.

The block head is aluminum, with two camshafts (DOHC) and 16 valves equipped with hydraulic compensators. A valve timing regulator is installed on the intake shaft.

Timing belt drive. Less noisy than chain, but more problematic. It is necessary to check the condition of the belt every 30 thousand km, and replace it after 90 thousand km. If the belt breaks, the valves bend.

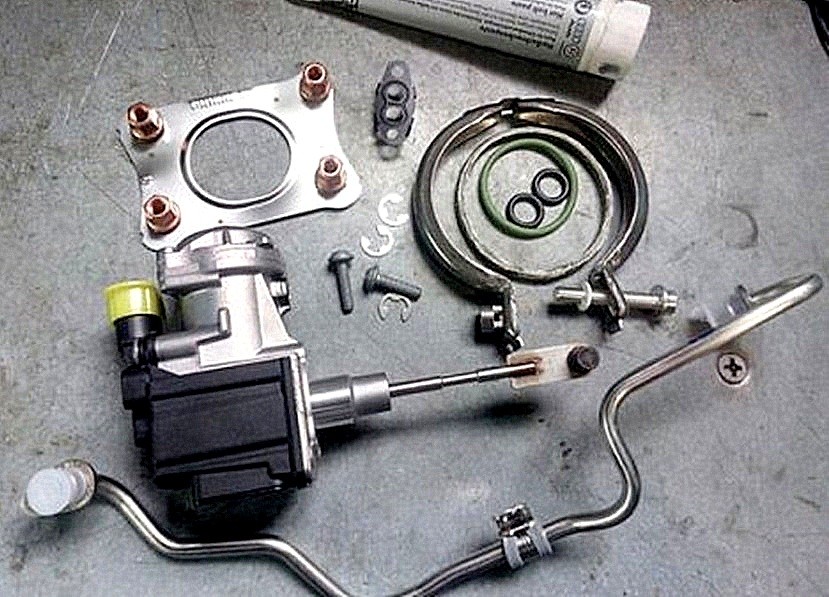

The turbine does not cause much trouble to the owner, but its drive makes fork out a significant amount. Sometimes you can get away with replacing the actuator, but in some cases you have to replace the entire turbine assembly.

The engine runs sluggishly on 95th gasoline, which additionally contributes to a number of serious problems and reduces the life of the unit.

The cooling system is double-circuit. The pump is plastic and not durable. Thermostats are recommended to be replaced after 90 thousand kilometers. The pump takes a little more care.

The engine is controlled by the Bosch Motronic MED 17.5.21 ECU.

Technical specifications

| Manufacturer | Mlada Boleslav Plant, Czech Republic |

| Release year | 2012 |

| Volume, cm³ | 1395 |

| Power, hp from | 122 |

| Power index, l. s/per 1 liter of volume | 87 |

| Torque, Nm | 200 |

| Compression ratio | 10 |

| Cylinder block | aluminum |

| Number of cylinders | 4 |

| Cylinder head | aluminum |

| Fuel injection order | 1-3-4-2 |

| Cylinder diameter, mm | 74.5 |

| The piston stroke, mm | 80 |

| Timing drive | belt |

| Number of valves per cylinder | 4 (DOHC) |

| Turbocharging | turbine Mitsubishi TD025 M2 |

| Hydraulic compensators | Yes |

| Camshaft adjuster | one (inlet) |

| Lubrication system capacity, l | 3.8 |

| Applied oil | 5W-30 |

| Oil consumption (calculated), l / 1000 km | up to 0,5* |

| Fuel system | injector, direct injection |

| Fuel | gasoline AI-98 (RON-95) |

| Environmental standards | Euro 5 |

| Resource, outside. km | 250 |

| Weight, kg | 104 |

| Location | transverse |

| Tuning (potential), l. With | over 200** |

* without loss of resource 155 ** on a serviceable engine no more than 0,1

Reliability, weaknesses, maintainability

Reliability

Unfortunately, CMBA does not belong to the category of reliable ones. The manufacturer has determined a mileage resource of 250 thousand km, but practice shows that the engine fails much earlier. Many car owners had to repair the unit after 70 thousand km.

By properly operating the internal combustion engine, you can achieve an increase in mileage. But this “correct” is not always possible to implement. For example, the quality of our fuels and lubricants, especially gasoline, causes a lot of criticism. There are many cases when car owners independently try to fix some malfunctions with their own hands, without having the proper experience in repair work, (“according to the book”).

The manufacturer keeps the engine reliability issues under constant control. So, in September 2013, the design of the cylinder head was changed. The maslozhor noticeably decreased, but did not completely disappear. Other improvements to the unit also did not give the expected result. The engine remained problematic.

CMBA has a good margin of safety. It can be boosted up to 200 liters. s, but at the same time exacerbate all existing "sores". Tuning fans need to know that a simple chip tuning (Stage 1) raises the power to 155 hp. s, more complicated (Stage 2) already up to 165. But again, remember that any intervention in the design of the motor will significantly reduce its already small resource.

Weak spots

Increased oil consumption (maslozhor). The occurrence is due to defects in the cylinder head, valve stem seals and piston rings.

Breakdown in the turbine control drive (jamming of the wastegate actuator rod). Provoking a malfunction is the incorrect selection of materials for drive parts and the long-term operation of the internal combustion engine in the same rhythm (almost with constant engine speed).

Unsuccessful design of ignition coils - often break even when replacing candles.

Coolant leak from the water pump unit with two thermostats. The reason lies in the wrong gasket material.

Slow engine warm up. The main problem lies in the cylinder head.

Noisy operation of the unit. Most often manifested during acceleration and deceleration. The specific source of the problem has not been identified.

Maintainability

The opinion on maintainability was vividly expressed by Profi VW from Moscow: “... maintainability - no! Modular design, modules change assemblies". It is supported by the vast majority of car owners.

Overhaul is a big problem. The crankshaft is not replaced separately, only assembled with the block. This means that in most cases it is pointless to do boring of sleeves.

Smaller repairs are possible. There are no problems with spare parts. But given the high cost of restoring internal combustion engines, many car owners come to the decision to purchase a contract CMBA. Its cost depends on the mileage, completeness of attachments and other factors. The price of a "working" engine starts from 80 thousand rubles.

The Volkswagen CMBA engine as a whole turned out to be an unreliable, unfinished unit. Many car owners come to the conclusion that it is advisable to replace it with another, more reliable internal combustion engine.