Volkswagen CLRA engine

Content

Russian motorists appreciated the advantages of the Volkswagen Jetta VI engine and unanimously recognized it as one of the best.

Description

In Russia, the CLRA engine first appeared in 2011. The production of this unit is established at the plant of the VAG concern in Mexico.

The engine was equipped with Volkswagen Jetta cars of the 6th generation. The delivery of these cars to the Russian market was carried out until 2013.

Essentially, CLRA is a clone of CFNA known to our motorists. But this motor managed to absorb a lot of the positive qualities of the analogue and reduce the number of shortcomings.

CLRA is another gasoline four-cylinder aspirated engine with an in-line arrangement of cylinders. The declared power is 105 liters. s at a torque of 153 Nm.

The cylinder block (BC) is traditionally cast from an aluminum alloy. Thin-walled cast-iron sleeves are pressed into the body. The main bearing beds are machined integrally with the block, so their replacement during repair is not possible. This means that, if necessary, the crankshaft must be changed along with the BC assembly.

The block head is made with a transverse cylinder scavenging scheme (the intake and exhaust valves are located on opposite sides of the cylinder head). On the upper plane of the head is a bed for two cast iron camshafts. Inside the cylinder head there are 16 valves equipped with hydraulic compensators.

Aluminum pistons with three rings. Two upper compression, lower oil scraper. The piston skirts are graphite coated. The piston bottoms are cooled by special oil nozzles. The piston pins are floating, secured against axial displacement by retaining rings.

Connecting rods steel, forged. In the section they have an I-section.

The crankshaft is fixed in five bearings, rotates in thin-walled steel liners with an anti-friction coating. For more precise balancing, the shaft is equipped with eight counterweights.

The timing drive uses a multi-row lamellar chain. According to car owners, with timely maintenance, 250-300 thousand km are easily nursed.

Despite this, the previous defect in the drive still remained. It is discussed in detail in Chap. "Weak spots".

Fuel supply system injector, distributed injection. The recommended gasoline is AI-95, but motorists claim that the use of AI-92 does not affect the operation of the unit at all. The system is controlled by the Magnetti Marelli 7GV ECU.

The combined lubrication system has no special design.

In general, according to car owners, CLRA fit into the group of the most successful VAG engines.

Technical specifications

| Manufacturer | VAG car concern |

| Release year | 2011* |

| Volume, cm³ | 1598 |

| Power, hp from | 105 |

| Power index, l. s/1 liter volume | 66 |

| Torque, Nm | 153 |

| Compression ratio | 10.5 |

| Cylinder block | aluminum |

| Number of cylinders | 4 |

| Cylinder head | aluminum |

| The working volume of the combustion chamber, cm³ | 38.05 |

| Fuel injection order | 1-3-4-2 |

| Cylinder diameter, mm | 76.5 |

| The piston stroke, mm | 86.9 |

| Timing drive | chain |

| Number of valves per cylinder | 4 (DOHC) |

| Hydraulic compensators | Yes |

| Turbocharging | no |

| Camshaft adjuster | no |

| Lubrication system capacity, l | 3.6 |

| Applied oil | 5W-30, 5W-40 |

| Oil consumption (calculated), l / 1000 km | 0,5** |

| Fuel system | injector, port injection |

| Fuel | gasoline AI-95 |

| Environmental standards | Euro 4 |

| Resource, outside. km | 200 |

| Location | transverse |

| Tuning (potential), l. With | 150*** |

*date of appearance of the first engine in the Russian Federation; ** on a serviceable internal combustion engine, not more than 0,1 l; *** without loss of resource up to 115 l. With

Reliability, weaknesses, maintainability

Reliability

The reliability of any engine lies in its resource and safety margin. There is information about the mileage that 500 thousand km is not the limit for him. But at the same time, its timely and high-quality service is put at the forefront.

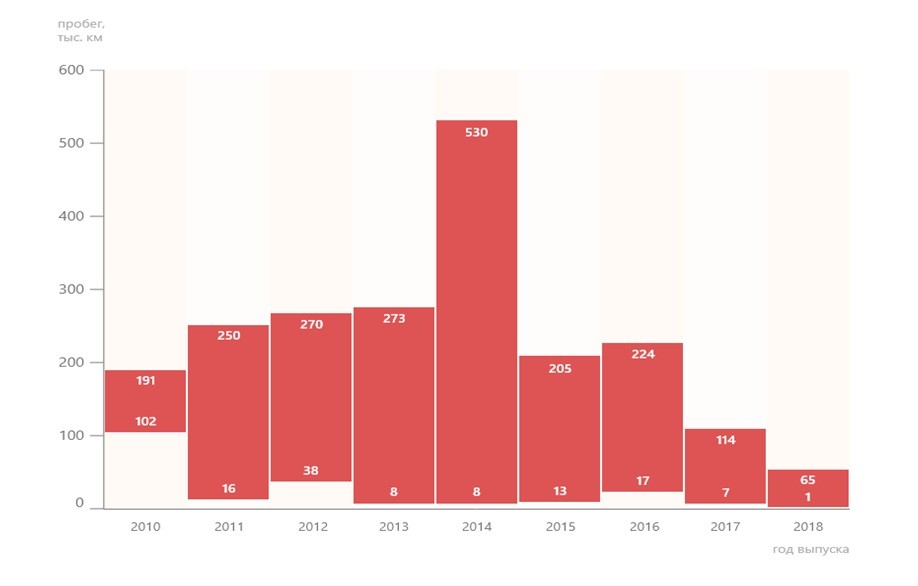

The graph shows that the engine mileage exceeds 500 thousand km.

The use of high-quality oil helps to increase the resource of the unit. From the photo below it is clear that the mismatch of the brand of the recommended oil leads to the effect of "draining" the internal combustion engine elements that need lubrication. The same picture is observed when the terms of its replacement are not observed.

It is clear that in this case, the durability of the motor should be forgotten.

The manufacturer, when improving the timing drive, focused on increasing its service life. Modernization of the chain and tensioner increased their resource to 300 thousand km.

The engine can be boosted up to 150 hp. s, but you don't have to do it. Firstly, such intervention will significantly reduce the life of the motor. Secondly, technical characteristics will change, and not for the better.

If it’s completely unbearable, then it’s enough to flash the ECU (simple chip tuning) and the engine will additionally receive 10-13 hp. forces.

The vast majority of car owners characterize the CLRA as a reliable, hardy, durable and economical engine.

Weak spots

CLRA is considered a very successful version of Volkswagen engines. Despite this, there are weaknesses in it.

Many motorists are bothered by a knock when starting a cold engine. Bulldozer 2018 from Stavropol speaks on this topic as follows: “… Jetta 2013. Engine 1.6 CLRA, Mexico. 148000 thousand km mileage. There is noise when starting on a cold 5-10 seconds. And so, like, everything is fine. Definitely chain motors are noisier».

There are two reasons for the knocks that appear - the wear of the hydraulic lifters and the shifting of the pistons to TDC. On new engines, the first reason disappears, and the second is a design feature of the internal combustion engine. When the engine warms up, the knock disappears. This phenomenon will have to come to terms.

Unfortunately, the timing drive has taken over the problems of its predecessor. When the chain jumped, the bending of the valves remained inevitable.

The essence of the problem lies in the absence of a hydraulic tensioner plunger stopper. As soon as the pressure in the lubrication system has dropped, the drive chain tension is immediately loosened.

It follows from this that there is only one way to exclude the possibility of a jump - do not leave the car with the gear engaged in the parking lot (you need to use the parking brake) and do not try to start the car from a tow.

Some car owners have problems with the ignition-injection system. In this case, candles and a throttle assembly are subject to careful analysis. The use of low-quality gasoline leads to carbon deposits in the throttle and its drive, which negatively affects the operation of the engine.

And, perhaps, the last weak point is the sensitivity to the quality of the oil and the timing of its replacement. Ignoring these indicators in the first place leads to increased wear of the crankshaft liners. What this leads to is clear without explanation.

Maintainability

The simple design of the engine implies its high maintainability. This is true, but here it is necessary to take into account the complexity of the restoration work. For car services, this is not critical, but self-repair will lead to irreversible consequences.

The essence of the problem comes down to a thorough knowledge of the technological processes of restoration, equipping with the necessary tools and devices. For example, a common operation is setting TDC.

If there is no dial indicator, then it is not even worth taking on this work. In this case, the fixtures must necessarily include camshaft and crankshaft clamps, and of course a special tool.

It's not easy to replace the crankshaft seal. Not everyone knows that after installing a new one, it takes four hours to stand without turning the crankshaft. Violation of the technological process will cause the destruction of the stuffing box.

Spare parts for motor repair are easy to find in any specialized store. The main thing is not to buy counterfeit products. Repair of the unit is carried out only using original spare parts.

Watch this video on YouTube

Cast iron sleeves allow you to change the CPG in full. Boring liners to the desired repair size provides a full overhaul of the internal combustion engine.

When restoring the engine, you immediately need to be prepared for significant material costs. The high cost of repairs is due not only to expensive spare parts, but also to the complexity of the work performed.

For example, re-sleeving of a cylinder block requires the involvement of highly qualified specialists. Accordingly, their pay will be increased.

Based on the foregoing, it will not be superfluous to consider the option of acquiring a contract engine. The average price of such a motor is 60-80 thousand rubles.

The Volkswagen CLRA engine left the best impressions on Russian motorists. Reliable, powerful and economical, and with timely maintenance, it is also durable.