Volkswagen DJKA engine

Content

The engine builders of the Volkswagen concern (VAG) have expanded the EA211-TSI (CHPA, CMBA, CXSA, CZEA, CZCA, CZDA) line with a new power unit, called the DJKA.

Description

The release of the motor was launched in 2018 at the production facilities of the VAG auto concern. At the same time, two versions of the internal combustion engine were produced - under Euro 6 (with a particulate filter) and under Euro 5 (without it).

On the Internet you can find information about the assembly of the unit in Russia (in Kaluga, in Nizhny Novgorod). A clarification is required here: the engine itself was not produced at Russian factories, but was installed on manufactured models already in finished form.

The CZDA, well known to our motorists, has become an analogue of the design.

DJKA, like its predecessor, is designed on the principle of a modular platform. The positive aspects of this decision were the reduction in the weight of the unit, the availability of spare parts and the simplification of repair technology. Unfortunately, this was reflected in the cost of restoration in the direction of its increase.

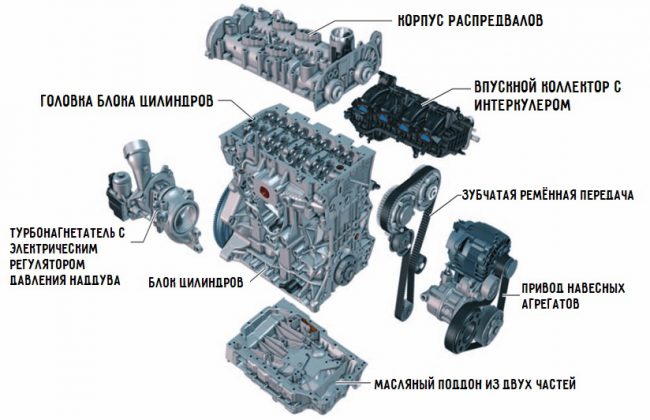

The Volkswagen DJKA engine is a gasoline, in-line, four-cylinder turbo engine with a volume of 1,4 liters and a power of 150 hp. with and torque of 250 Nm.

The internal combustion engine was installed on VAG cars:

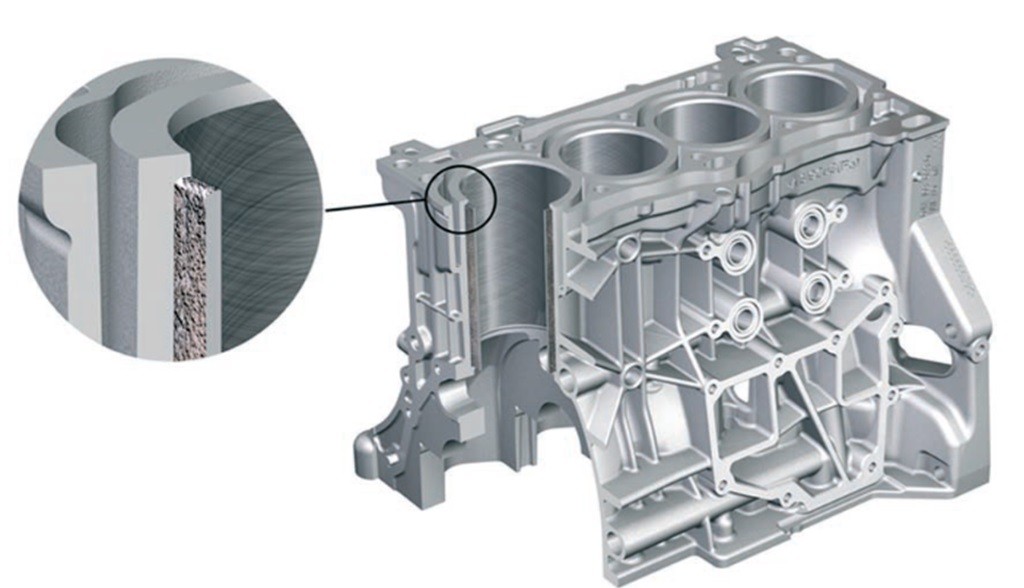

The cylinder block is cast from aluminum alloy. Thin-walled cast-iron sleeves are pressed into the body. To increase the area of contact with the block, their outer surface has a strong roughness.

The crankshaft is mounted on five bearings. Feature - the inability to individually change the shaft or its main bearings. Only assembled with cylinder block.

Aluminum pistons, lightweight, standard - with three rings.

Supercharging is carried out by an IHI RHF3 turbine, with an overpressure of 1,2 bar.

Aluminum cylinder head, 16-valve. Accordingly, two camshafts, each with a valve timing regulator. The valves are equipped with hydraulic compensators. The cylinder head itself is turned 180˚, i.e. the exhaust manifold is at the back.

Timing belt drive. Belt resource - 120 thousand km. After 60 thousand km of run, a mandatory condition check every 30 thousand km. A broken belt causes serious engine damage.

Fuel supply system - injector, direct injection. The manufacturer recommends using AI-98 gasoline in the conditions of the Russian Federation. It more fully reveals the potential of the internal combustion engine. The use of AI-95 is allowed, but you need to know that the European and Russian fuel standards are different. RON-95 in its parameters corresponds to our AI-98.

The lubrication system uses oil with tolerances and viscosity VW 508 00, VW 504 00; SAE 5W-40, 10W-40, 10W-30, 5W-30, 0W-40, 0W-40. The volume of the system is 4,0 liters. An oil change must be made after 7,5 thousand kilometers.

The engine is controlled by an ECM with a Bosch Motronic MED 17.5.25 ECU.

The motor does not cause serious complaints in its address; typical problems have not yet been noted by car owners.

Technical specifications

| Manufacturer | plant in Mlada Boleslav, Czech Republic |

| Release year | 2018 |

| Volume, cm³ | 1395 |

| Power, hp from | 150 |

| Torque, Nm | 250 |

| Compression ratio | 10 |

| Cylinder block | aluminum |

| Number of cylinders | 4 |

| Cylinder head | aluminum |

| Fuel injection order | 1-3-4-2 |

| Cylinder diameter, mm | 74.5 |

| The piston stroke, mm | 80 |

| Timing drive | belt |

| Number of valves per cylinder | 4 (DOHC) |

| Turbocharging | IHI RHF3 turbine |

| Hydraulic compensators | Yes |

| Camshaft adjuster | two (inlet and outlet) |

| Lubrication system capacity | 4 |

| Applied oil | 0W-30 |

| Oil consumption (calculated), l / 1000 km | 0,5* |

| Fuel system | injector, direct injection |

| Fuel | gasoline AI-98 (RON-95) |

| Environmental standards | Euros 5 (6) |

| Resource, outside. km | 250 |

| Weight, kg | 106 |

| Location | transverse |

| Tuning (potential), l. With | 200++ |

*on a serviceable engine no more than 0,1; ** without damage to the motor up to 180

Reliability, weaknesses, maintainability

Reliability

The reliability of the CJKA is beyond doubt. The successful design of the motor and the manufacturer's modifications to eliminate the shortcomings inherent in the EA211-TSI series provided the engine with high reliability.

As for the resource, a proper conclusion cannot yet be made due to the rather short life of the internal combustion engine. True, the mileage of 250 thousand km appointed by the manufacturer is puzzling - too modest. What the engine is capable of in reality will become clear after a certain time.

The unit has a large margin of safety. More than 200 liters can be removed from it. with power. But it is advisable not to do this. According to the reviews of car owners, the power is quite enough for driving around the city and for driving on the highway.

At the same time, if desired, you can flash the ECU (Stage 1), which will add about 30 hp to the engine. With. At the same time, all modes of protection, regular mixture formation and diagnostics of internal combustion engines are stored at the factory level.

More aggressive chip tuning methods have a negative impact on technical characteristics (reducing the resource, lowering environmental emission standards, etc.) and require significant intervention in the engine design.

Conclusion: CJKA is reliable, powerful, efficient, but technically complex.

Weak spots

The use of modern technologies and innovations in the assembly of the engine has yielded results. A number of problems that caused car owners a lot of trouble disappeared.

So, the unreliable turbine drive and the appearance of the oil burner have sunk into oblivion. The electrician has become more enduring (candles are not damaged when they are unscrewed).

Perhaps, today DJKA has one weak point - when the timing belt breaks, the valve bends.

With a stretch, the weaknesses include the high cost of spare parts. For example, if the water pump in the coolant system breaks down, you will have to change the entire module, in which thermostats are additionally installed. And this is much more expensive than replacing the pump separately.

Thus, if we do not take into account the sometimes occurring unauthorized noises during engine operation, we can assume that the manufacturer has managed to eliminate almost all the weak points in the unit.

Maintainability

The modular design of the unit is conducive to its high maintainability. But this does not mean that DJKA can be repaired "on your knees" in any garage.

High-tech assembly and saturation with electronics oblige to restore the unit only in a car service.

Repair parts are easy to find in any specialized store, but you should immediately be ready to pay a rather considerable amount for them. And the repair itself is not cheap.

Sometimes it is more profitable to purchase a contract engine than to repair a broken one. But here, too, you need to be prepared for serious investments. The cost of contract DJKA starts from 100 thousand rubles.

The modern DJKA motor with a small volume allows you to remove impressive power, quite economical, while meeting the high requirements of the environmental standard.