Lifan engines for motoblocks

Content

The Lifan engine for a push tractor is a universal power unit designed for installation in small agricultural, gardening and construction equipment by the largest Chinese company Lifan, which since 1992 has specialized in the production of not only equipment, but also motorcycles, cars, buses, scooters. High-performance engines are supplied both to the CIS countries and to the markets of Europe and Asia.

Lifan engines have a wide range of products. Everything is suitable for pushers, cultivators, snow plows, ATVs and other equipment.

When choosing an engine model, it is necessary to take into account the operating conditions, the brand of the tractor on which the engine will be installed, the volume and types of work performed on the sites, the type of power source and engine power, the diameter and location of the output shaft.

Technical specifications

For push tractors, petrol models are excellent: Lifan 168F, 168F-2, 177F and 2V77F.

Model 168F belongs to the group of engines with a maximum power of 6 hp and is a 1-cylinder, 4-stroke unit with forced cooling and a crankshaft position at an angle of 25°.

The engine specifications for the push tractor are as follows:

- The volume of the cylinder is 163 cm³.

- The volume of the fuel tank is 3,6 liters.

- The cylinder diameter is 68 mm.

- Stroke 45 mm.

- Shaft diameter - 19mm.

- Power - 5,4 l s. (3,4 kW).

- Rotation frequency - 3600 rpm.

- Start is manual.

- Overall dimensions - 312x365x334 mm.

- Weight - 15kg.

Of particular interest to users of push tractors is the 168F-2 model, since it is a modification of the 168F engine, but has a longer resource and higher parameters, such as:

- power - 6,5 l s.;

- cylinder volume - 196 cm³.

The cylinder diameter and piston stroke are 68 and 54 mm, respectively.

Of the 9-liter engine models, the Lifan 177F is distinguished, which is a 1-cylinder 4-stroke gasoline engine with forced air cooling and a horizontal output shaft.

The main technical parameters of Lifan 177F are as follows:

- Power - 9 liters with. (5,7 kW).

- The volume of the cylinder is 270 cm³.

- The volume of the fuel tank is 6 liters.

- Piston stroke diameter 77x58 mm.

- Rotation frequency - 3600 rpm.

- Overall dimensions - 378x428x408 mm.

- Weight - 25kg.

The Lifan 2V77F engine is a V-shaped, 4-stroke, overhead valve, forced air-cooled, 2-piston gasoline engine with a non-contact magnetic transistor ignition system and a mechanical speed control. In terms of technical parameters, it is considered the best of all heavy class models. Its characteristics are as follows:

- Power - 17 hp. (12,5 kW).

- The volume of the cylinder is 614 cm³.

- The volume of the fuel tank is 27,5 liters.

- The cylinder diameter is 77 mm.

- Stroke 66 mm.

- Rotation frequency - 3600 rpm.

- Starting system - electric, 12 V.

- Overall dimensions - 455x396x447 mm.

- Weight - 42 kg.

The resource of a professional engine is 3500 hours.

Fuel consumption

For engines 168F and 168F-2, fuel consumption is 394 g/kWh.

The Lifan 177F and 2V77F models can consume 374 g/kWh.

As a result, the estimated duration of work is 6-7 hours.

The manufacturer recommends using AI-92(95) gasoline as fuel.

Traction class

Light motoblocks of traction class 0,1 are units up to 5 liters with. They are purchased for plots up to 20 acres.

Medium motor blocks with a capacity of up to 9 liters when processing areas up to 1 ha, and heavy motor cultivators from 9 to 17 liters with a traction class of 0,2 cultivate fields up to 4 hectares.

Lifan 168F and 168F-2 engines are suitable for Tselina, Neva, Salyut, Favorit, Agat, Cascade, Oka cars.

The Lifan 177F engine can also be used for medium-sized vehicles.

The most powerful gasoline unit Lifan 2V78F-2 is designed to work in difficult conditions on mini tractors and heavy tractors, such as Brigadier, Sadko, Don, Profi, Plowman.

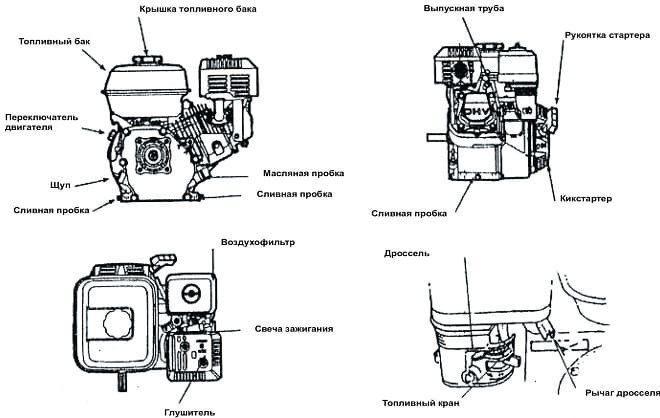

Устройство

According to the engine manual for the push tractor and cultivator, the Lifan 4-stroke internal combustion engine has the following components and parts:

- Fuel tank with filters.

- Fuel cock.

- Crankshaft.

- Air filter.

- Start off.

- Spark plug.

- Air damper lever.

- Drain plug.

- Oil stopper.

- Muffler.

- Throttle lever.

- Research.

- Engine switch.

- The working cylinder.

- Valves of the gas distribution system.

- Crankshaft bearing bracket.

The motor is equipped with an automatic protection oil level control system, in some models it has a built-in gearbox to reduce the speed of rotation of the shaft. The gas distribution system is equipped with intake and exhaust valves, manifolds, and a camshaft.

Advantages

A walk-behind tractor with a Lifan engine has the following advantages:

- employment stability;

- High Quality;

- reliability;

- low noise and vibration levels;

- small overall dimensions;

- the use of a cast-iron bushing to increase the motor resource;

- ease of operation and maintenance;

- wide margin of safety;

- long service life;

- paid price.

All these qualities distinguish Lifan engines from other engines.

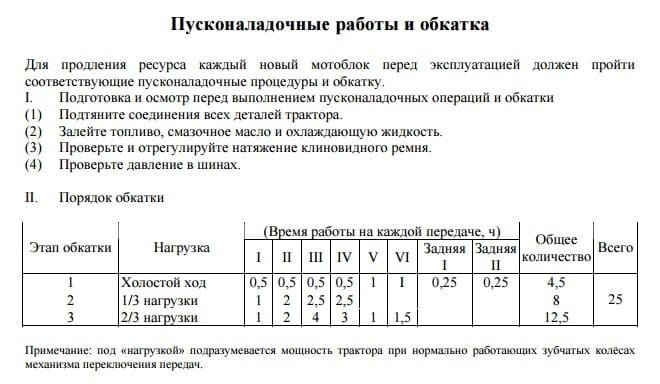

Running in a new engine

Engine operation is a mandatory procedure that extends the life of the mechanism. To start the engine of a pushing tractor, it is necessary to follow the operating instructions for the product, use high-quality fuel and oil of recommended grades.

Shooting is done as follows:

- Before starting the engine, check the oil level in the crankcase.

- Check and, if necessary, add oil to the gearbox.

- Fill the fuel tank with fuel.

- Start the engine at low speed.

- Start the push tractor in a smooth manner by shifting gears alternately. Work the soil in 2 passes to a depth of no more than 10 cm in 1 pass, cultivate in 2nd gear.

- After break-in, change the oil in the engine, drive units, motoblock gearbox, inspect consumables, replace oil filters, fill in fresh fuel.

- The break-in procedure takes about 8 hours.

After a quality run-in of the new engine, the pusher is ready for operation with maximum loads.

Engine service

To ensure the quality operation of the Lifan engine for a push tractor, regular maintenance is necessary, which includes the following items:

- Checking the oil level, topping up.

- Cleaning and replacing the air filter.

Every 6 months you need to do the following:

- Sewer cleaning.

- Adjustment and replacement of spark plugs.

- Treatment of the spark arrester.

The following procedures are carried out annually:

- Checking and adjusting the idle speed of the engine.

- Setting up optimal valve sets.

- Complete oil change.

- Cleaning of fuel tanks.

The fuel line is checked every 2 years.

Adjustment of valves

Valve adjustment is a necessary procedure when servicing an engine. According to the regulations, it is carried out once a year and consists in establishing the optimal clearances for the intake and exhaust valves. Its permissible value for each engine model is presented in the technical data sheet of the unit. For standard push tractors, they have the following meanings:

- for the intake valve - 0,10-0,15 mm;

- for the exhaust valve - 0,15-0,20 mm.

Gap adjustment is carried out with standard probes 0,10 mm, 0,15 mm, 0,20 mm.

With the correct adjustment of the intake and exhaust valves, the engine will run without noise, knocking and jerking.

Change of oil

Carrying out an oil change operation is an important procedure that affects many driving characteristics and improves the operation of the mechanism.

The frequency of the procedure depends on many factors:

- operating frequency;

- technical condition of the engine;

- terms of Use;

- the quality of the oil itself.

Oil change is carried out as follows:

- Place the engine on a level surface.

- Remove the oil pan dipstick and drain plug.

- Drain the oil.

- Install drain plug and close tightly.

- Fill the crankcase with oil, check the level with a dipstick. If the level is low, add material.

- Install dipstick, tighten securely.

Do not dump used oil on the ground, but take it in a closed container to a local disposal point.

What kind of oil to fill in the engine

The manufacturer recommends using engine oil for a walk-behind tractor that meets the requirements of GOST 10541-78 or API: SF, SG, SH and SAE. Type of low-viscosity substance - mineral oil 10W30, 15W30.

How to install a Lifan engine on a walk-behind tractor

Each model and class of push tractor has its own engine. Let's look at these examples:

- Motoblock Ugra NMB-1N7 with a Lifan engine corresponds to version 168F-2A in terms of technical characteristics.

- Motoblock Salyut 100 - version 168F-2B.

- Middle class Yugra NMB-1N14 - Lifan 177F engine with a capacity of 9 liters.

- Agates with Lifan engines can be equipped with models 168F-2 and Lifan 177F.

- Oka with a Lifan 177F engine, when supplemented with accessories, will work better and more economically. Model 168F-2 with a volume of 6,5 liters is also suitable for the Oka MB-1D1M10S motoblock with a Lifan engine

The engine can be installed on the Ural, Oka, Neva pushers according to the following algorithm of actions:

- Remove the old engine guard, belts and pulley by unscrewing the bolts.

- Remove the air cleaner filter to disconnect the throttle cable.

- Remove the engine from the push tractor frame.

- Install the engine. If necessary, a transition platform is installed.

- A pulley is attached to the shaft, a belt is pulled for better operation of the caterpillar, adjusting the position of the motor.

- Fix the transition deck and engine.

When installing the motor, the user must take care of the mounting hardware.

Motoblock Cascade

When installing an imported Lifan engine on a domestic Cascade pusher, the following additional parts are required:

- pulley;

- transition platform;

- adapter washer;

- gas cable;

- crankshaft bolt;

- bras

Mounting holes in the frame do not match. For this, a transition platform is purchased.

The cascade is equipped with a domestic DM-68 engine with a capacity of 6 hp. When replacing the engine with Lifan, the 168F-2 model is chosen.

Motoblock Mole

When installing the Lifan engine on a Krot tractor equipped with an old domestic engine, installation kits are required when replacing, which include elements such as:

- pulley;

- adapter washer;

- gas cable;

- crankshaft bolt.

If the push tractor had an imported engine, then a Lifan engine with an output shaft diameter of 20 mm is sufficient for installation.

Installing the Lifan engine on the Ural walk-behind tractor

The factory equipment of the Ural pushers implies the presence of a domestic engine. In some cases, the power and performance of such an engine is not enough, which is why it is necessary to redo the equipment. It is quite simple to equip the Ural push tractor with a Lifan engine with your own hands; however, before starting work, you need to decide on the purpose for which the equipment is being created, to choose a suitable engine.

Certain motors are suitable for cultivators of different types and weights, so it is important that the parameters match. The heavier the pushing tractor, the more powerful the engine must be. For the Urals, models such as Lifan 170F (7 hp), 168F-2 (6,5 hp) are suitable. They require minimal modification to install.

The main feature that distinguishes Chinese engines from domestic ones is the direction of rotation of the shaft, for Lifan it is left, for Ural factory engines it is right. For this reason, the push tractor is set to rotate the axle to the right; to install a new motor, it is necessary to change the position of the chain reducer so that the pulley is on the opposite side, allowing it to rotate in the other direction.

After the gearbox is on the other side, the motor is installed in the standard way: the motor itself is fixed with bolts, belts are put on the pulleys and their position is adjusted.

Lifan engine reviews

Vladislav, 37 years old, Rostov region

The Lifan engine was installed on the pushing tractor Cascade. Works for a long time, failures are not observed. Installed it myself, bought an installation kit. The price is affordable, the quality is excellent.

Igor Petrovich, 56 years old, Irkutsk region

Chinese is just great. It consumes little fuel and works efficiently. I brought my Brigadier a powerful 15 hp Lifan petrol engine. Feel the power This works great. Now I trust the high quality of Lifan.