Dual mass flywheel, common rail and turbocharging - how to reduce the risk of failure of modern diesel engines?

Modern diesel engines beckon with good performance, high maneuverability, high work culture and low fuel consumption. The price for this is a more complex and expensive design to repair. But some breakdowns can be avoided with proper operation.

Modern diesel engines beckon with good performance, high maneuverability, high work culture and low fuel consumption. The price for this is a more complex and expensive design to repair. But some breakdowns can be avoided with proper operation.

The times when diesels were simple, even primitive designs, are gone forever. Turbocharged diesel engines became commonplace in the 1.9s and Volkswagen gained a lot of fame with its immortal XNUMX TDI engine. These engines had good performance and were economical but noisy.

Recent developments are much quieter, comparable to gasoline engines. They have a power of more than 150 hp. and huge torque, making them ideal for long trips. And they were created with them in mind. Here is an overview of the technical solutions used in modern diesel engines, a list of their biggest problems and how to avoid them.

Dual-mass flywheel - thanks to it, the diesel does not vibrate

The increasing torque achieved by engines at low speeds and the overall deformation of the structure cause more frequent occurrence of torsional vibrations in the crank-rod system. At the same time, manufacturers are trying to reduce the weight of the drive unit by using light-alloy materials with low vibration damping. These factors lead to high vibrations of the running engine, which have a devastating effect on the gearbox, propeller shafts, joints and bearings. They cause inconvenience to the driver and passengers.

To overcome the problem of vibrations, dual-mass flywheels are increasingly being used in diesel engines (but also in gasoline engines). This element simultaneously performs the functions of a classic flywheel and vibration damper. As the name suggests, this node consists of two so-called masses, primary and secondary. Between them is a vibration damper, which, thanks to springs and discs, reduces most of the vibrations generated by the drive system.

To overcome the problem of vibrations, dual-mass flywheels are increasingly being used in diesel engines (but also in gasoline engines). This element simultaneously performs the functions of a classic flywheel and vibration damper. As the name suggests, this node consists of two so-called masses, primary and secondary. Between them is a vibration damper, which, thanks to springs and discs, reduces most of the vibrations generated by the drive system.

How to take care of a dual mass flywheel?

The design of a dual-mass flywheel is complex, and the element itself is subjected to significant overloads. All this means that its service life is short. That is why it is so important how the car is operated. Although the dual mass flywheel helps to save fuel by providing a smooth ride at low revs, it should not rotate below 1500 rpm during operation. Below this value, vibrations occur that overload the damping elements of the flywheel. Hard starts and harsh acceleration also cause this expensive component to wear faster. Riding on a coupling half is allowed only in exceptional cases, as it causes overheating of the entire system and a change in the consistency of lubricants for the popular two-mass, as a result of which moving parts can seize.

See also: Glow plugs in diesel engines - work, replacement, prices. Guide

As you can see, constant operation in city traffic, frequent starts and gear changes do not serve the state of the dual-mass flywheel; it achieves the greatest trouble-free mileage in vehicles covering long and quiet routes. Typical signs of wear are an audible knock at idle, vibrations and jerks when you press the gas hard. The peak resource of a dual-mass flywheel is 150-200 thousand. km (with a gentle driving style). In case of non-compliance with the recommendations and the prevalence of operation in city traffic, the dual-mass flywheel may need to be replaced already at a mileage of less than 100 km. km.

Dual mass flywheel - how much does it cost to buy a new one and how much does it cost to restore?

Prices for new dual-mass wheels vary depending on the make and model of the car, for example (manufacturers: LUK and Valeo):

- Opel Vectra C 1.9 CDTI 120 km - PLN 1610,

- Renault Laguna III 2.0 dCi 130 km - PLN 2150,

- Ford Focus II 1.8 TDCI 115 km – PLN 1500,

- Honda Accord 2.2 i-CTDi 140 km – 2260 zł.

To the above amounts should be added labor costs, which will average PLN 500-700. This is not enough, so usually the dual mass wheel is replaced along with the clutch to avoid double and costly dismantling of the transmission. It is worth mentioning the possibility of regeneration of the dual-mass flywheel. This operation will allow you to save up to half the amount that you would have to spend on buying a new component. However, it should be borne in mind that the wheel will regain the performance and durability of a new part only when all its worn and faulty components are replaced. Typically replaced: springs, multi-groove bushing, spacers, shoes that separate the selector from the upper and lower plates, high-temperature grease. It is also important that the fitted parts match the model.

Turbocharger - thanks to him, the diesel has a kick

Turbocharger - thanks to him, the diesel has a kick

Strict exhaust emission regulations forced the use of turbochargers even in small engines. From the point of view of manufacturers, this is a profitable solution, since the cost of increasing the power of a car with a turbocharger is much lower for them than the classic modifications of the head and drive transmission. Not without importance are factors such as reducing the weight of the engine and reducing fuel consumption and the above-mentioned emissions of carbon dioxide and other harmful substances.

Each turbocharger consists of two main parts: a turbine and a compressor. The turbine rotor is driven by the engine's exhaust gases and reaches speeds of over 200 rpm. It is connected by a shaft to the compressor rotor. The connecting system is bearing and lubricated with engine oil. The rotors are protected from oil ingress by means of O-rings. The task of the turbocharger is to pump an additional portion of air into the intake manifold, with an average pressure of 000-1,3 bar. As a result, the engine burns more fuel in a shorter time, which increases the efficiency of the process and therefore the performance of the vehicle.

How to care for a turbocharger?

Almost all diesel engines produced today are equipped with a turbocharger. The solution is very popular, but, unfortunately, it is sensitive to improper operation and quite emergency. It is not allowed to start quickly and reach high speeds shortly after starting the engine. The turbine needs to be allowed time to warm up, spin up and get proper lubrication. The last point is extremely important: it is important to ensure that the engine oil is of the highest quality and purity, and it should also be changed more often. The replacement interval is best halved, as recommended by the manufacturer (in most cases it will be 7-10 thousand km). After a long drive at high speeds, do not immediately turn off the engine, but wait about two minutes at low speeds until the turbocharger rotors slow down and the whole thing cools down a bit. If the above recommendations are followed, the service life of the turbocharger should be extended.

Turbocharger regeneration

However, if the bearings seize or the rotor is damaged, the turbocharger can usually be rebuilt. It consists in a thorough cleaning of the turbine and the replacement of worn parts. In the case of a less complex system, i.e. a turbine with a fixed rotor blade geometry, this procedure usually gives the expected results, and everything, including labor, can cost less than PLN 1000. However, in the case of systems with variable geometry, where there are additional so-called exhaust vanes around the circumference of the turbine rotor, the matter is much more complicated. The exhaust guides are blades that, by changing their position, regulate the boost pressure and help bring it to the optimum values depending on the engine speed. This allows you to limit the occurrence of so-called. turbo circles. Due to the lower combustion temperature of diesel fuel, these systems are mainly used in diesel engines.

New turbochargers with variable blade geometry can cost even more than PLN 5000, so it is not surprising that drivers decide to regenerate worn components. Unfortunately, it happens that the procedure, the cost of which often exceeds PLN 2000, does not bring the expected results - without specialized equipment and service equipment, it is impossible to carry out repairs in such a way as to preserve the original engine parameters. In extreme cases, cars lose up to half their rated power and torque. When deciding to remanufacture a variable blade geometry turbocharger, we must choose the most professional and modern workshop. There is a market for new turbocharger replacements, but due to their usually terrible quality and inconsistency, such a solution is not worth considering.

- You can recognize a worn turbocharger by the following symptoms: the car smokes heavily from the exhaust pipe, since less air supplied by the compressor causes more soot, whistling and metallic squeaks are heard when driving at low load, the car may be “dirty”. We should also be concerned about any oil leaks from the turbocharger,” says Zbigniew Domański, Moto-Mix Service Specialist in Siedlce.

F particulate filter (DPF / FAP) - thanks to it, the turbodiesel does not smoke

particulate filter (DPF / FAP) - thanks to it, the turbodiesel does not smoke

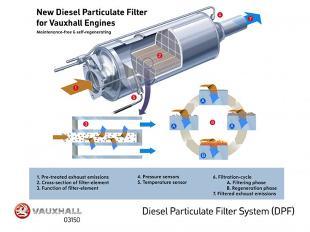

Soot cleaning technology was used in response to the introduction of EU emission standards Euro 4 and Euro 5. DPF (dry filtration) and FAP (soot afterburning) filters are now used in almost all diesel vehicles manufactured today. Particulate filters are located in the exhaust system, most often after the catalytic converter, and consist of a housing and an element. The insert is made of a numerous network of silicon carbide channels coated with soot absorbing compounds. Unfortunately, the filter options are limited. Manufacturers have provided a filter self-cleaning procedure, which consists in burning soot in it. The process usually occurs every few thousand kilometers. However, there must be appropriate conditions for this, i.e. the possibility of stable driving at high speeds for 10-15 minutes. So, you need to drive on the freeway or highway.

Soot afterburning treatment is not always effective; There were cases when an additional portion of fuel, dosed to increase engine speed, and hence the temperature of the exhaust gases, went into the engine oil, diluting it. The risk of such an event arises primarily in the event that the afterburner procedure is interrupted by the driver, for example, in the event of an unforeseen situation on the road: sudden braking, gear changes and, thus, the deviation of the engine from increased speed. The consequences can be very dangerous for the condition of the engine, as well as for the turbocharger, which is lubricated with oil. In addition, there are always non-combustible parts in the soot, the accumulation of which, sooner or later, will lead to permanent clogging of the filter, which entails the need to replace it. And this is always a cost of several thousand zlotys, often a new filter is estimated at 10000 zlotys.

How to care for a particulate filter?

City driving can be deadly for diesel particulate filters. When the vehicle is not being used on motorways, the conditions in the exhaust system are not sufficient to burn off the soot. The most important thing here is driver awareness. If we use our car most of the time in the city, it costs every 2-3 thousand. kilometers, go on a trip of several tens of kilometers along the expressway.

See also: Modern diesel engine - is it possible and how to remove a particulate filter from it - a guide

Even despite following the recommendations, the service life of a typical filter does not exceed 150-200 thousand mileage. km. A sign of a clogged filter is usually a drop in power and the engine goes into emergency mode. Then you can still try to force the carbon removal procedure under operating conditions, but this is not always effective. On the other hand, the removal of the filter is always associated with a number of other improvements (exhaust, software) and costs PLN 1500-3000. It is also an illegal decision, and a car converted in this way has no chance of meeting the stringent emission standards. This could end up with police holding on to evidence, or problems passing a mandatory vehicle inspection at a vehicle inspection station.

Fuel injectors - a diesel engine owes them performance and low fuel consumption.

Another important component of modern diesel engines are diesel fuel injectors, which today most often work in a common rail system. A typical injector consists of a body, a solenoid, a control valve, and an injection tip. The last two elements most often fail. If the valve is worn out, the fuel to be dosed is returned to the tank. Then we won't start the engine. On the other hand, the main sign of clogged or worn injector tips is black smoke. Common Rail injectors are divided into electromagnetic and piezoelectric injectors. Currently, there are no proven and effective technologies for the repair and regeneration of piezo injectors; measures are limited to their diagnostics and replacement with new ones.

Common rail injector regeneration

Common rail injector regeneration

However, cars are dominated by electromagnetic injectors, the regeneration of which is a very popular and effective repair method. Denso injectors are the infamous exception here. While spare parts and repair charts are available for Bosch and Delphi systems, Denso makes it impossible to repair its products from the start. The nozzles of this company are installed on cars of many Japanese brands, as well as on some Ford and Fiat cars. Recently, Denso has started to introduce a slightly more relaxed policy, and one authorized workshop has already been established in Poland, dealing with the regeneration of such injectors. Depending on the model (for example, Toyota), you can buy injectors there at prices ranging from PLN 700 to PLN 1400 each, which is less than half the cost of a new item available from the manufacturer.

See also: Regeneration and repair of diesel injectors - the best injection systems

Regeneration of Bosch and Delphi systems is much cheaper; We will receive a full-fledged component in the amount of PLN 200 to 700, and the cost of a completely new one will be from PLN 900 to 1500. Prices do not include the cost of work - from PLN 200 to 300 for the assembly of the kit. However, for piezoelectric injectors that cannot be repaired, we will have to pay from 1000 to 1500 zł per piece; examples of models in which they were used: Skoda Octavia 2.0 TDI CR, Renault Laguna 2.0 dCi, Mercedes E320 CDI.

How to care for injectors in a diesel engine with a common rail system and not only?

Injector failures in diesel engines are usually caused by poor quality diesel fuel. For modern designs, so-called sulfur-free fuels are used, since sulfur contributes to the rapid wear of injector nozzles. The presence of water and impurities in the fuel can end the life of injectors very quickly, as they have to withstand pressures up to 2000 bar.

The only, but so far dubious preventive method is refueling only at proven branded stations. Remember to change the fuel filter regularly; Also, periodic cleaning of the fuel tank in Polish conditions is seen as a rational preventive solution. Even when refueling with diesel fuel at good stations, after a run of 50 thousand. km at the bottom of the fuel tank there may be a large amount of sludge, which, when sucked by the pump, will damage the injectors.

See also: New compact car - comparing the cost of buying and operating popular models

– When operating a vehicle with a modern diesel engine, it is essential to follow all recommendations of the vehicle manufacturer. The most important thing is regular and professional maintenance, because these engines, due to their complexity, require special care. However, even by following these rules and using your vehicle wisely in mixed traffic, you probably won't avoid injector failure or a clogged diesel particulate filter. Therefore, even before buying a car, you should think about its usually less troublesome petrol version, because often the money saved on fuel has to be left at the service station, advises Zbigniew Domański.