Operation and maintenance of a manual transmission

Content

Purpose and device of a mechanical "box"

The manual transmission transmits the torque developed by the engine to the drive wheels through the transmission. It is a multi-stage gearbox with a variable gear ratio.

The clutch housing (case) is combined with the engine into a single power unit, the front bearing of the input shaft of the box is installed at the rear end of the engine crankshaft.

The clutch mechanism is normally engaged and constantly connects the engine crankshaft flywheel to the gearbox input shaft. The clutch only works during a gear change, disengaging the engine and gearbox and ensuring their smooth reconnection.

In the body of the power unit of front-wheel drive vehicles, there is also a differential gearbox that distributes torque between the drive shafts of the transmission and allows the wheels to rotate at different angular speeds.

Manual transmissions are divided into:

- by the number of gear ratios:

- four-stage;

- five-stage, the most common;

- six-speed.

- according to the kinematic scheme:

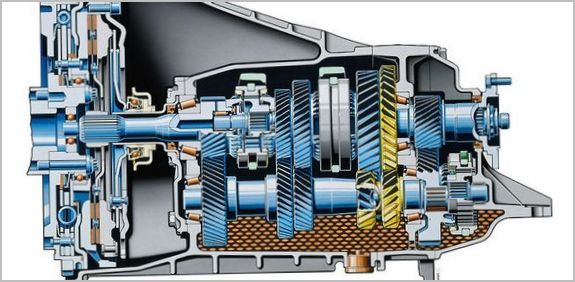

- two-shaft, in the crankcase of a four- or five-speed box, primary and secondary shafts are installed;

- three-shaft, gearbox gearbox consists of primary, intermediate and secondary shafts.

By default, the number of gearbox stages does not include neutral and reverse gears, the number of shafts does not include the reverse gear shaft.

The toothed gears of gearboxes are helical in type of engagement. Spur gears are not used due to increased noise during operation.

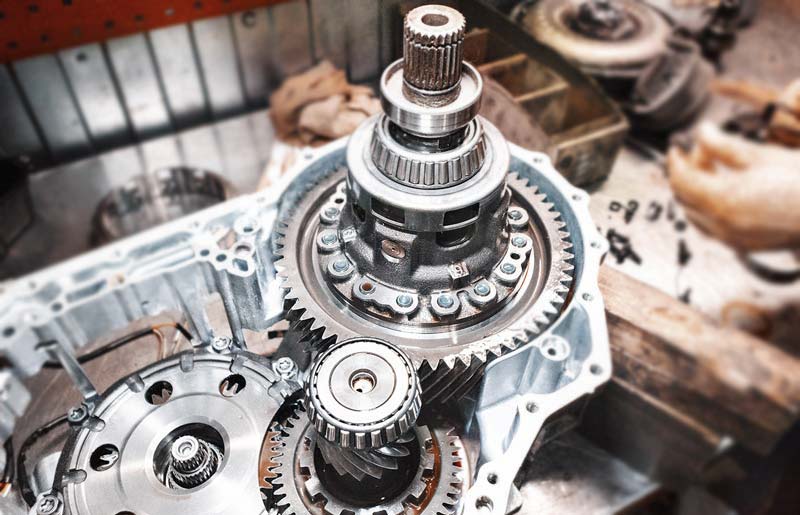

All shafts of mechanical boxes are mounted in rolling bearings, radial or thrust, mounted in accordance with the direction of the longitudinal force that occurs in helical gearing. In three-shaft designs, the primary and secondary shafts are located coaxially and, as a rule, have a common needle bearing.

The gears rotate and move on shafts on plain bearings - pressed bushings made of low-friction copper alloys.

For shockless operation, synchronizers are installed that equalize the speed of rotation of the gears at the time of switching.

The gear ratios of mechanical gearboxes are unified by the world's main manufacturers and look like this:

- First gear - gear ratio 3,67 ... 3,63;

- The second - 2,10 ... 1,95;

- Third - 1,36 ... 1,35;

- Fourth - 1,00 ... 0,94;

- Fifth - 0,82 ... 0,78, etc.

- Reverse gear - 3,53.

The gear, in which the engine crankshaft speed practically coincides with the number of revolutions of the secondary shaft of the box, is called direct (usually fourth).

From it, in the direction of reducing the number of revolutions of the secondary shaft, at constant engine speeds, downshifts go, in the direction of increasing the number of revolutions - increased gears.

Gear shifting mechanism

All manual transmissions use lever-rocker designs, in which the gears of the box, when shifting gears, are moved by forks moving along parallel rods under the force of the lever. From the neutral position, the lever is deflected by the driver to the right or left (gear selection) and back and forth (shifting).

Switching mechanisms according to the principle of operation are divided into:

- Traditional, or classic, allowing you to turn on any gear from "neutral".

- Sequential, allowing only sequential switching.

Sequential mechanisms are used on motorcycles, tractors, and in units with more than six gears - trucks and tractors.

Manual transmission management

A novice driver should be taught this at a driving school.

Sequencing:

- Get into a parked car with the engine off. Close the driver's door, take a comfortable position in the chair, fasten your seat belt.

- Make sure the parking brake is on and the shift lever is in neutral.

- Start the engine.

Attention! From the moment you launch, you drive a car and are the driver of a vehicle.

- Squeeze the clutch pedal, engage the desired gear (first or "reverse", you are leaving the parking lot).

- Lightly press on the gas pedal. When the tachometer shows about 1400 rpm, gently release the clutch pedal, disengaging the parking brake. The car will start moving, but the clutch pedal cannot be abruptly “thrown”, it should be continued to move smoothly until the clutch mechanism discs are fully in contact, adjusting the speed of movement with the gas pedal.

The first gear is needed in order not only to move the car from its place, but also to accelerate it to a speed at which, without jerking and stopping the engine, it will be possible to turn on the “second” and continue to move confidently.

Upshifting should be done slowly, the movements of the left leg, which controls the clutch, are deliberately slow. The right foot releases the gas synchronously with the left clutch release, the right hand confidently works the shift lever and “sticks” the gear without waiting for the car to slow down.

With experience, the “mechanics” control algorithm goes to the subconscious level, and the driver intuitively works with the clutch and “handle”, without looking at the controls.

How to choose the speed and engine speed at which you need to shift gears

In a simplified form, engine power is the product of the torque it develops and the number of revolutions of the crankshaft.

With a properly functioning clutch mechanism, all the power is perceived by the input shaft of the manual transmission and goes through the gear system and transmission to the drive wheels.

The manually operated gearbox of the "mechanical box" transforms the transmitted power in accordance with the desires of the driver, which do not always coincide with the capabilities of the motor and real driving conditions.

When shifting gears “up”, you should not allow an excessive decrease in the speed of the machine during pauses.

When changing gears “down”, a delay is required between disengaging the clutch and moving the shift lever so that the parts of the box slow down somewhat in their rotation.

When moving in direct and higher gears, you do not need to “twist” the engine to the limit, if you need a jerk when overtaking or overcoming a long climb, you should switch to a step or even two “lower”.

Economy driving mode

In the text of the documentation for any car, you can find "maximum torque (such and such), at a speed (so much)". This speed, i.e. the number of revolutions of the crankshaft per minute, and there is the value at which the engine will provide the greatest tractive effort with the minimum fuel consumption.

Maintenance

A manual transmission, when used correctly, is a very reliable unit that, like any other mechanical gearboxes, requires the only type of maintenance - an oil change.

Gear oils are used for lubrication, which, in addition to high viscosity, have specific anti-seize and anti-wear properties, temperature stability, compressive strength of the oil film and a low coefficient of surface tension, which does not allow liquid to drain from lubricated surfaces. In addition, gear oil must be neutral in acidity, preventing erosion of gearbox parts made of non-ferrous metals.

The brand of transmission oil and the interval between changes are indicated in the vehicle's operating instructions.

The gearbox is an expensive unit, when servicing it, use only the recommended oil.

Attention! Do not believe "life hacks" like "how to determine the brand of oil by smell, taste and color using a piece of paper."

During operation, gear oil decreases in volume only due to evaporation, does not burn out and does not fly “down the pipe” like engine oil, but becomes contaminated with friction products and darkens with aging.

Major faults

The vast majority of malfunctions, which are considered to be the fault of the manual transmission, are caused by malfunctions in the operation of the clutch. The most common:

- The reverse gear is switched on with a “crunch”, other gears are switched with difficulty - the drive adjustments are violated, the clutch “leads”.

- Monotonous noise or buzzing when depressing the clutch pedal - wear of the release bearing.

Malfunction of the power unit as a whole:

A distinct noise when coasting with the gear engaged and the clutch depressed - the gearbox front bearing in the engine crankshaft failed.

Malfunctions in the mechanical "box" are most often introduced by the owner of the car or his predecessors, sometimes associated with general wear and tear as a result of long-term operation:

- Squealing when downshifting. Wear or failure of standing synchronizers.

- Reverse does not turn on - the gear is destroyed or the switching fork is deformed due to attempts to “turn on the reverse” without waiting for the car to stop completely.

- Difficult to select transmission. Worn shift lever ball joint.

- Incomplete engagement of gears, inability to engage or disengage one of them, arbitrary disengagement of gears when the gas is released. Wear of ball detents or guide rods, deformation of shift forks. Rarely - the destruction of the gear teeth.

Advantages of manual transmission in various road conditions

In a car with "mechanics", the driver does not feel detached from direct control of the car.

As experience is gained, useful skills and techniques appear and improve:

- Engine braking. It is necessary when driving on ice, during long descents from the mountain and in other situations when you need to use long and smooth braking without overheating the brakes and losing contact of the wheels with the road.

- Riding "stretch" with the clutch partially depressed. Useful when moving over difficult terrain and overcoming individual obstacles at speed without shock loads in the transmission.

- Quick shifts "first, reverse, first." It makes it possible to "rock" the car and independently drive out of the swamp or snowdrift in which it is stuck.

- Ability to coast, tow and tow colleagues on the road yourself

- Fuel economy. In any gear, you can choose the most economical driving mode.

Also, the invaluable advantage of manual transmission is simple maintenance, long service life, availability of repairs and low cost of consumables.