Where is the crankshaft sensor located on a Honda SRV

Content

I don’t know the layout of this engine, but everything looks as if the DPKV adjusting gear disk is not attached directly to the crankshaft, but to some other shaft driven from the crankshaft through a gear / chain / belt (perhaps on the camshaft, or on some intermediate shaft, or on the camshaft). If this is the case, then the signal from this DPKV will not contain accurate information about the instantaneous speed of the crankshaft, since the connection between the drive disk and the crankshaft is not rigid enough. And since there is no exact information in the original token, the CSS script will not be able to extract it from this token.

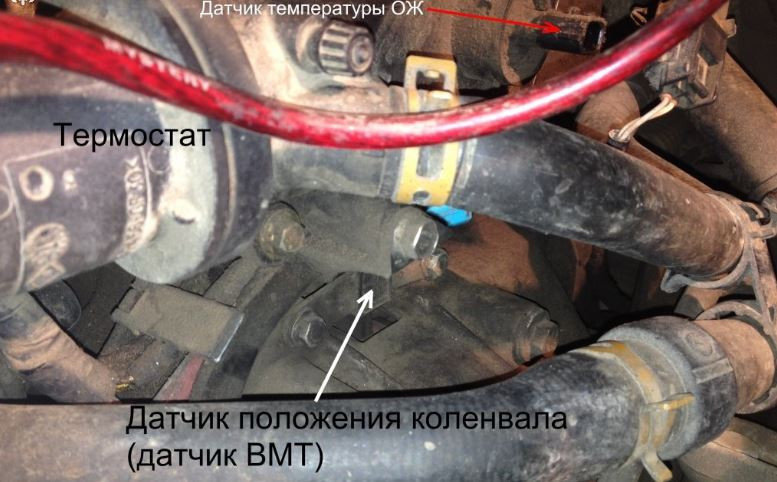

I just started reading this thread. And since the topic was created a long time ago, I was not going to answer here anymore. But, after reading to the end, I found out that you can still have this car and decided to answer. If possible: specify where the crankshaft sensor is located, where its drive disk is located. It would be nice to see a photo.

In fact, the crankshaft position sensor serves as an analog transmitter for synchronizing the process of ignition of the fuel mixture in the combustion chambers of the internal combustion engine at the very moment when the piston compresses it. The signal is transmitted to the on-board computer, the sensor itself is installed near the engine flywheel.

Purpose of DPKV sensor

In modern automotive electronic ignition systems, the fuel mixture is injected into the cylinders, and the spark is supplied from the spark plug after it is compressed by the on-board computer. The DPKV sensor is used to determine the spatial position of the pistons at a given time. It is this electronic device that transmits the signal to the ECU to perform the sequence of actions specified by the electronic ignition of the car.

Regardless of which modification of the crankshaft sensor is used, the symptoms of a malfunction of this device are expressed in the absence of a spark / fuel injection or a violation of this cycle. In other words, the internal combustion engine cannot be started or the engine spontaneously stops after a while. This indicates a distortion of the piston position signal at the bottom and top dead center.

Less often, the cable connecting the DPKV to the ECU is damaged, in this case the signal is not sent to the on-board computer, the operation of the engine is impossible in principle.

What ICE is installed on?

Such a device cannot be mounted on cars without an on-board computer, and on carburetor engines. Therefore, DPKV is present only in diesel engines and injection engines. To find out the location of the crankshaft sensor, it is necessary to take into account the features of its operation:

- parts of the crank group, pulleys and flywheel are attached to the crankshaft;

- The KShM is hidden in the tray, the belts of the same gears are placed on the pulleys, so it is very difficult to fix the sensor near these parts;

- the flywheel is the largest part, it belongs to several engine systems at once, so the DPKV is attached close to it to provide quick access when replacing.

Caution: The crankshaft position sensor is considered a maintenance-free electronic device. It is diagnosed and replaced when a complete fault is found.

DPRV sensor

In addition to the crankshaft sensor, a DPRV sensor can be installed in the internal combustion engine, which is responsible for supplying the fuel mixture and spark to a specific cylinder in the engine. It is not the main electrical apparatus, unlike the crankshaft, it is mounted on the camshaft. Its second name is a pulse-type phase sensor.

If the PRV is defective, the engine will not stop working, but the injectors will fire twice as often in pair-parallel mode until the problem is corrected.

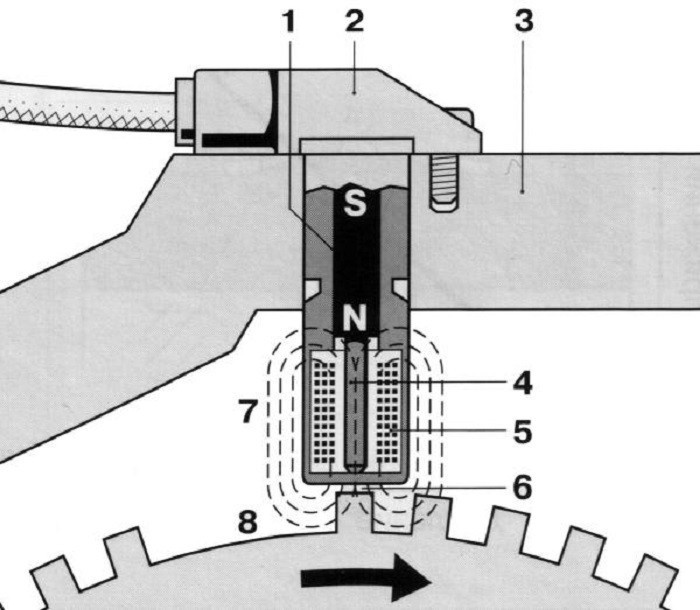

Design and principle of operation of the crankshaft sensor

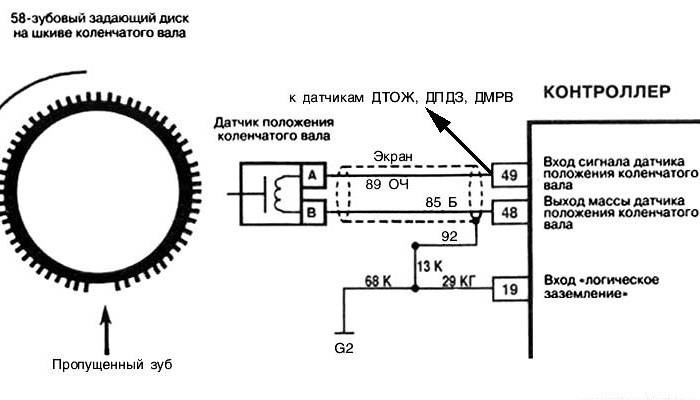

In order for the sensor to transmit a signal over a cable to a computer microcontroller, the following principle is used:

- especially two flywheel teeth are omitted;

- turning all the teeth of the flywheel near the DPKV, they distort the magnetic field that is generated in the coil of the device;

- at the moment of passage near the sensor of the section of the crown with the missing tooth, the interference disappears;

- the device sends a signal about this to the computer, and the computer determines the exact position of the pistons in each cylinder.

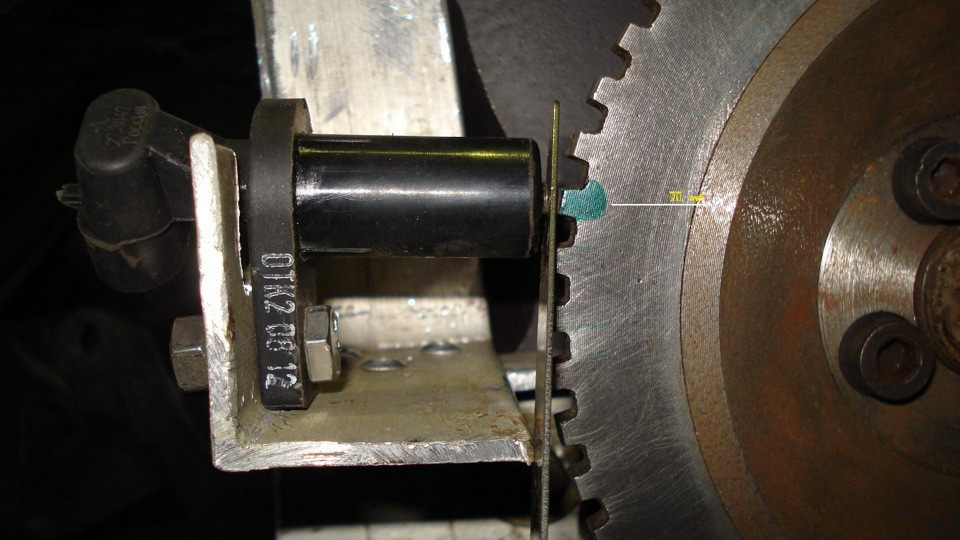

Correct operation is possible only with a gap of 1 to 1,5 mm between the teeth of the flywheel ring gear and the electrode of the device. Therefore, there are wedges above the DPKV seat. And the corresponding cable with a length of 0,5 - 0,7 m from the computer is equipped with a turnkey connector.

The ECU software allows you to calculate the position of the pistons in cylinders I and IV when a signal is received and the direction of rotation of the shaft. This is enough for the correct generation of signals to the fuel supply and ignition sensor.

Optic

Structurally, this sensor consists of an LED and a receiver. The signal is generated at the receiver by passing through the part of the flywheel with worn teeth, since at this time the LED beam is not completely blocked by the rest of the teeth.

These simple actions do not allow you to use the device for any further operations. In the event of a malfunction (ignition desynchronization), the DPKV is replaced along with the cable.

Hall Sensor

Working on the principle of potential difference in the cross section of metals (Hall effect), the crankshaft position sensor has an additional function of distributing ignition to the combustion chambers of the cylinders.

A fairly simple principle of operation of the sensor is based on the appearance of voltage due to a change in the magnetic field. Without a flywheel with two sharpened teeth, this device will not work.

Inductive

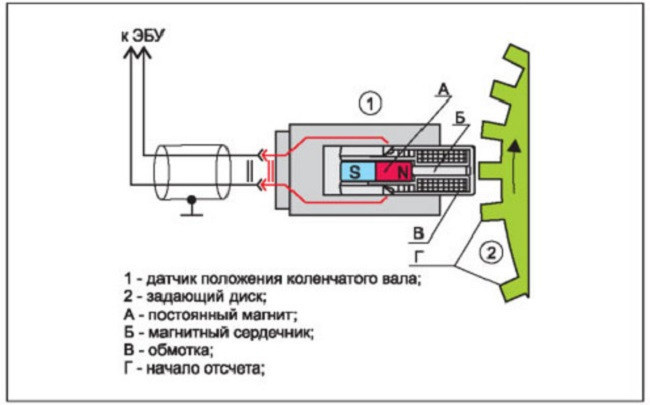

Unlike previous modifications, the magnetic crankshaft position sensor works by electromagnetic induction:

- a field is constantly generated around the device;

- voltage to supply a signal to the microprocessor occurs only when it passes through the section of the flywheel ring gear, on which there are no teeth.

Axle position control is not the only option of this device, it also serves as an axis speed sensor.

Since the magnetic device and the Hall sensor are multifunctional devices, they are most often used in motors.

Location of DPKV

Even with a dense arrangement of components and assemblies of the machine under the hood, manufacturers are trying to ensure the availability of DPKV for quick replacement on the road. Therefore, to understand where the crankshaft sensor is located is quite simple:

- it is located between the generator pulley and the flywheel;

- cable length is sufficient for free connection to the on-board network;

- there are adjusting wedges on the seat for setting a gap of 1 - 1,5 mm.

Thanks to the turnkey head, even a novice driver can remove the sensor.

Major faults

Traditionally, for most on-board electrical appliances, some signs of a crankshaft sensor malfunction are determined visually. For example, if Check is on the dashboard, the driver has an error code reader, the driver will display a score of 19 or 35.

More common faults are:

- spontaneous engine shutdown;

- lack of launch;

- emergency operation of injectors / injectors twice as often as the prescribed cycle (failure of the DPRV).

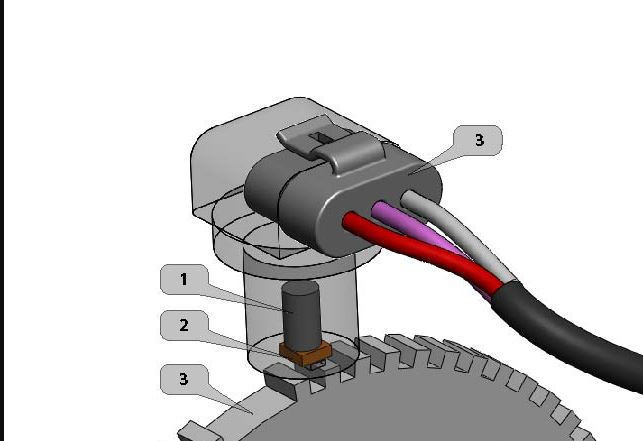

One of the available methods of self-diagnosis in this case is "sonification" with a tester. The internal resistance of the sensor winding must be between 500 and 800 ohms.

Repair may be required in case of mechanical damage to the device. For example, if dirt or foreign objects get on the surface of the flywheel rim, the signal will be distorted by them.

The timing disc may be accidentally magnetized during diagnostics. In this case, the repair consists in demagnetization using a special technique using a transformer at the service station.

If the resistance of the coil winding does not match the specified parameters, the car owner usually finds out by indirect signals:

- turns jump randomly;

- the dynamics of movement disappear or the power of the internal combustion engine is lost;

- at idle "floats";

- detonations occur during operation.

Attention: Since these malfunctions can be caused by other reasons, it is better to visit a service station for computer diagnostics. As a last resort, you should check the crankshaft sensor using available methods.

Diagnosis of DPKV and DPRV

When there are interruptions in the operation of the internal combustion engine, there can be many reasons. However, despite the somewhat inconvenient location, diagnosing the crankshaft sensor is the least time-consuming process. Then, depending on the results, further troubleshooting can be carried out or the crankshaft sensor can be replaced if the check reveals a malfunction. The principle of diagnostics is from simple to complex, that is, visual inspection, then checking with an ohmmeter, then with an oscilloscope or on a computer.

Attention: To check the DPKV, it is recommended to disassemble it, so you must immediately mark its position relative to the body.

Visual inspection

Since the sensor is installed with a gap setting, this distance must first be checked with a caliper. The following are the steps to visually check the crankshaft sensor:

- detection of foreign objects between it and the steering wheel;

- find dirt in the place of the missing teeth of the timing disc;

- wear or breakage of teeth (very rare).

In principle, at this stage, the car owner does not have any difficulties. Further verification should be carried out with instruments, preferably a multimeter (tester), which can be switched to ohmmeter, voltmeter and ammeter mode.

Ohmmeter

At this stage, checking the crankshaft position sensor does not require special knowledge and experience:

- the multimeter is set to the ohmmeter position (2000 Ohm);

- resistance is measured by a tester on the sensor coil;

- its value ranges from 500 to 800 ohms;

- any other value automatically indicates that the DPKV needs to be repaired.

Since the sensor is quite affordable, it is completely changed. Knowing where it is, you need to remove it with the battery terminals disconnected with a wrench.

Deep check

A thorough inspection is recommended before replacing the crankshaft sensor. The main conditions for its implementation are:

- room temperature (20 degrees);

- the presence of a transformer, sweep, voltmeter, inductance meter and megohmmeter.

The verification sequence is as follows:

- the transformer supplies 500 V to the winding;

- insulation resistance should be within 20 MΩ;

- coil inductance 200 - 400 mH.

If the specified parameters are within the normal range, and the test error is on the panel, then the cause of the malfunction lies in other internal combustion engine nodes. From the sensor, the signal is transmitted without distortion. If any characteristic deviates from the nominal value, it is necessary to replace the crankshaft position sensor.

Oscilloscope at the service station

In addition to the price that is unbearable for an ordinary motorist, the oscilloscope requires high qualifications from the user. Therefore, if we are talking about professional diagnosis of DPKV, it is better to contact a specialized car service.

The test is carried out on site, the cable is not disconnected from the computer:

- the device is set to inductive crank mode;

- the oscilloscope clamp is grounded;

- one connector is connected to USBAutoscopeII, the second one is connected to terminal A of the sensor;

- the engine is displaced by the starter or scrolls to the stop.

Any deviation in the amplitude of the waves on the oscilloscope screen will indicate that a distorted signal from the sensor is transmitted through the cable.

Nuances of operation of DPKV and DPRV sensors

In the event of a sudden breakdown of an electrical appliance on the road, normal starting and operation of the engine is not possible. Service station specialists recommend having a spare DPKV so that you can replace the crankshaft sensor with your own hands in the field. The device is inexpensive, with proper storage it cannot be damaged or broken. The rest of the details are:

- malfunction of the crankshaft position sensor - a rare malfunction, diagnostics are best done at a service station on an oscilloscope;

- having found signs of malfunction of the crankshaft position sensor, it is necessary to set a mark before disassembly;

- the recommended installation distance to the synchronizer disk is 1 mm;

- it is forbidden to diagnose breakdowns with a light bulb; work is carried out with the ignition off.

Thus, the crankshaft sensor is the only device in an internal combustion engine that synchronizes the ignition. A breakdown in 90% of cases completely immobilizes the car without the ability to get to the service station. Therefore, it is recommended to have a spare set of DPKV in the car.