Hydro compensators - what is it

The engine heats up during operation, which leads to the natural expansion of metal parts. Designers take into account this feature and therefore leave special thermal gaps. However, another feature of the engine is the gradual wear of parts, respectively, the gaps expand and we observe such negative aspects as a decrease in power, a decrease in compression, increased oil and fuel consumption, and the gradual destruction of engine parts.

An important element of any gasoline internal combustion engine is the gas distribution mechanism.

Its main elements:

- camshaft with cams machined on it;

- intake and exhaust valves;

- valve lifters;

- camshaft pulley (drives the shaft due to the timing belt).

We have listed only the main elements, but in reality there are more. The very essence of the timing is to ensure that the camshaft rotates synchronously with the crankshaft, the cams alternately press on the pushers (or rocker arms), and they, in turn, set the valves in motion.

Over time, gaps form between the working surfaces of the camshaft, pushers (or rocker arms in V-shaped engines). To compensate for them, they used to use a simple adjustment mode using special marks and wrenches. I had to adjust the gaps literally every 10-15 thousand km.

To date, this problem has practically disappeared thanks to the invention and widespread use of hydraulic compensators.

The device and principle of operation of the hydraulic compensator

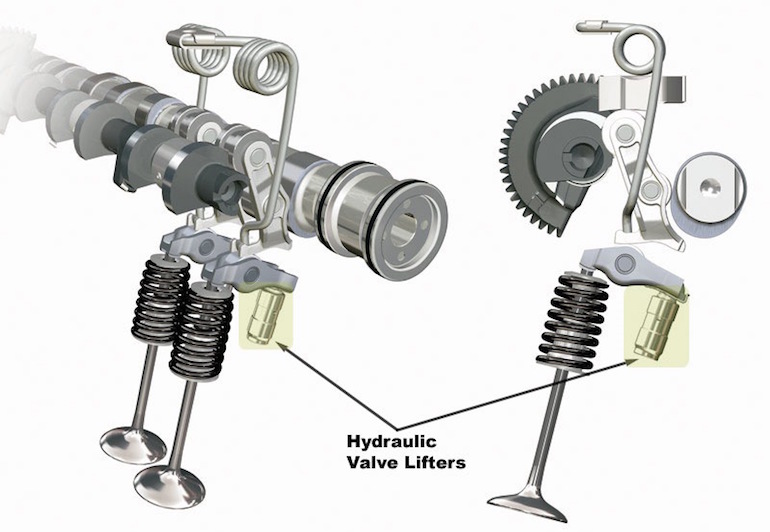

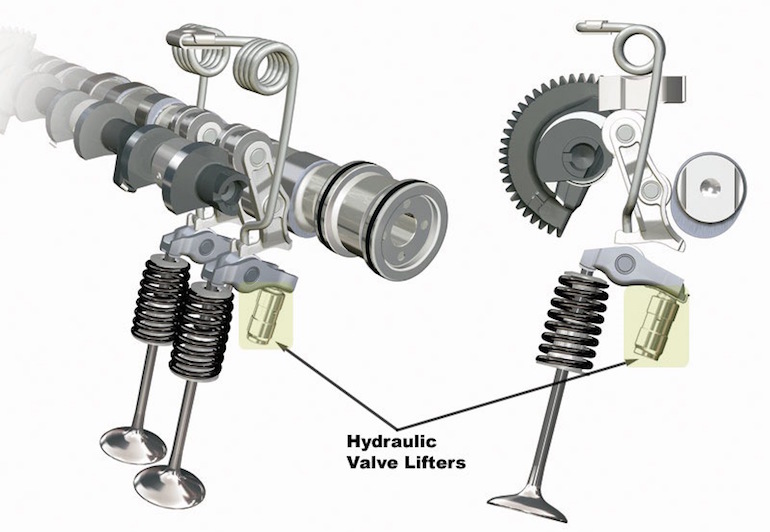

There are several basic types of hydraulic lifters designed to work with different types of timing (with pushers, rocker arms or lower camshaft installation). But the device itself and the principle of operation are basically the same.

The main elements of the hydraulic compensator:

- plunger pair (ball, spring, plunger sleeve);

- a channel for oil to enter the compensator;

- body.

The compensator is installed in the cylinder head in a specially designated place. It is also possible to install them on older types of engines in which their installation was not provided.

The principle of operation is quite simple. The camshaft cam has an irregular shape. When he does not press on the pusher, the gap between them increases. At this moment, the plunger spring presses on the plunger valve and oil from the lubrication system enters the compensator, the working part of the compensator rises slightly, sets the pusher in motion and the gap between the cam and the pusher disappears.

When the camshaft makes a revolution and the cam begins to load the pusher, the working part of the hydraulic compensator begins to lower until the oil supply channel is blocked. Accordingly, the pressure inside the compensator increases and is transmitted to the engine valve stem.

Thus, thanks to the compensators, the absence of gaps is ensured. If you still imagine that all this happens at a tremendous speed - up to 6 thousand revolutions per minute - then involuntarily there is admiration that such a simple invention could once and for all put an end to the problem of clearances in the valve mechanism.

It was thanks to the introduction of hydraulic compensators that it was possible to achieve such advantages of new engines over old ones:

- no need to constantly adjust valve clearances;

- engine operation has become softer and quieter;

- the number of shock loads on the valves and camshaft has decreased.

A small disadvantage from the use of hydraulic lifters is a characteristic knock that can be heard in the first seconds of starting a cold engine. This is due to the fact that the oil pressure in the system is insufficient, and the desired pressure indicators are achieved when the oil is heated to a certain temperature and expands, filling the internal cavities of the compensators.

The main problems of hydraulic lifters

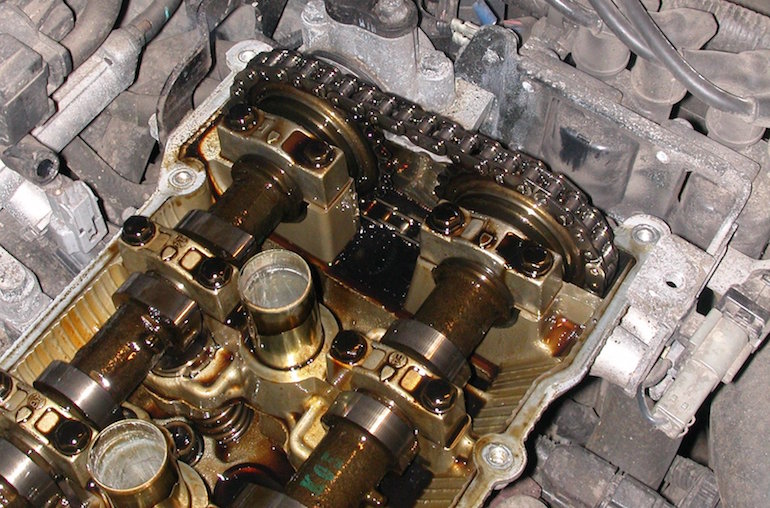

It is worth noting that the plunger pair of the compensator is a very accurate device. The gap between the sleeve and the plunger is a few microns. In addition, the oil outlet channel is also very small in diameter. Therefore, these mechanisms are very sensitive to the quality of the oil. They begin to knock and fail if low-quality oil is poured into the engine, or if it contains a lot of slag, dirt, sand, and so on.

If there are shortcomings in the engine lubrication system, then the oil will not be able to enter the compensators, and from this they will overheat and fail faster.

Specialists of the automotive portal vodi.su draws your attention to the fact that if hydraulic lifters are installed in the engine, then it is not recommended to fill it with high-viscosity oils, such as mineral 15W40.

When installing or replacing compensators, make sure they are filled with oil. They are usually shipped already filled. If there is air inside, then air congestion may occur and the mechanism will not be able to perform its tasks.

If the car has been idle for a long time, oil may leak from the compensators. In this case, you need to pump them: let the engine run at constant speed, then at variable speed, and then at idle - the oil will go to the compensators.

In this video, a specialist will talk about the device and principles of operation of hydraulic lifters.

Loading…