Hydrodistributor MTZ 82

Content

- Distributor design

- Common malfunctions of the MTZ distributor

- Connection of the hydrodistributor

- The R-80 hydraulic distributor for the MTZ-80 tractor - device, purpose and possible malfunctions

- Purpose and general arrangement of the MTZ hydraulic system

- The need for a hydraulic distributor on a tractor

- Mechanism and functioning of the hydraulic distributor MTZ 80

- Possible malfunctions of the hydrodistributor

- Hydrodistributor Р80-3/1-222

Together with the mechanical drive of machines? The MTZ-82(80) tractor is equipped with mechanisms that allow the transmission of tractor power due to oil pressure. Distribution, as well as control of oil flows under pressure, is carried out by a special unit of the tractor hydraulic system - a hydraulic distributor.

The hydraulic distributor MTZ 82 provides convenient aggregation and distribution of the pressure of the working fluid to all hydraulic power units of machines (hydraulic cylinders, hydraulic motors) and equipment used in conjunction with the tractor. With the help of a synchronizer, the unit provides simultaneous control of three hydraulic drives.

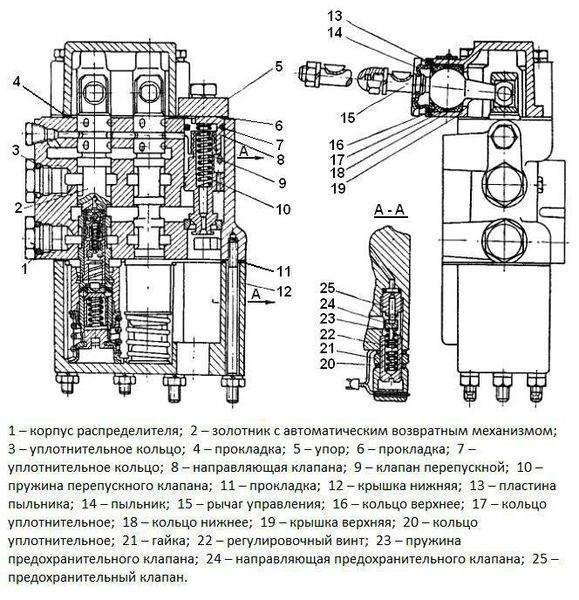

Distributor design

Hydrodistributing block MTZ 82(80) - R75-33R (GOST 8754-71)

- P - distributor

- 75 - performance unit liters per minute

- coil type 3, the design of which does not allow fixing in the "lowered" position

- 3 - the number of spools in the wiring diagram

- Q: The unit is designed to work with a power regulator

The design is made in a separate cast-iron housing with three through vertical spools and a channel for the bypass valve. The top and bottom of the case is closed with solid aluminum covers. The planes of connection of the covers and the body are sealed with gaskets and tightened with screws.

Hydrodistributor MTZ 80(82) R75-33R

The distributor has three working lines for supplying the working fluid, located perpendicular to the course of changing the position of the spools; discharge line "B" - connects the cavities of the bypass valves and spools, drain line "C" - connects the openings of the spools, the control line of the bypass valve "G" passes through the distributor housing and holes in the spools, The pipeline is connected to the bypass valve 14 The piston of the bypass valve is equipped with a throttle jet 13 to create a pressure drop in the discharge channel and cavities under the piston, which ensures its opening in the neutral position.

Coils block and open working lines with throttle slots. Management is carried out using levers, which are located on the bottom cover of the distributor. The levers are connected to the spools through a spherical hinge 9 with plastic inserts 10 and a sealing ring 8. From the outside, the hinge is closed with a rubber bushing 6. Three spools allow you to simultaneously control the operation of three hydraulic actuators.

Principle of operation

Each drum, depending on the set position, operates in four modes:

- "Neutral": The midpoint between the top "up" position and the bottom "down" position. The bypass valve is open and discharges the working fluid to the drain. The spools block all channels, fixing the previously set position of the hydraulic actuators.

- "Rise": the first highest position after "neutral". The bypass valve closes the drain cavity. The spool passes oil from the discharge channel to the cylinder lift line.

- "Forced descent" - the lowest position before the "floating" end. The bypass valve closes the drain cavity. The spool passes oil from the discharge channel to the return line of the hydraulic cylinder.

- "Floating" - the lowest position of the lever. The bypass valve is open and discharges the working fluid from the pump to the drain. In this position, the working fluid flows freely in both directions from both cavities of the hydraulic cylinder. The hydraulic cylinder is in a free position and reacts to the action of external conditions and to the machine's own gravity. Thus, it allows the working bodies of the machine to follow the terrain during tillage and maintain a stable tillage depth.

Spool retainer operation

The spools are equipped with a spring valve 3 for automatic return to the neutral position and ball detents that hold them in the selected position. The automatic reverse ball valve is activated when the pressure in the system exceeds 12,5-13,5 MPa. Excessive pressure occurs when the hydraulic cylinder reaches the end position in the corresponding forced lifting and lowering position, as well as when the system is overloaded.

The hydraulic distributor is equipped with an emergency pressure relief device 20. The safety valve is adjusted to relieve pressure over 14,5 to 16 MPa. The adjustment is made by screw 18, which changes the degree of compression of the spring of the ball valve 17. The device is triggered when the mechanism fails - the spool of the machine and the bypass device fail.

Common malfunctions of the MTZ distributor

Attachment does not lift

This could be caused by debris entering the hydraulic system below the bypass valve. In this case, the bypass valve does not close - the working fluid goes into the drain cavity. The dealer does not react to changing the position of the reels. Removed: unscrew the two bolts on the bypass valve cover, remove the spring with the valve and remove the debris.

In the situation of absence or decrease in the load capacity of the tractor hydraulics, accompanied by overheating of the oil in the system, the appearance of a hissing sound in the “lift” lever position indicates a drop in the oil level and air leakage in the system.

Attachment does not lock in raised position

The reason is the depressurization of high-pressure hydraulic hoses and hydraulic couplings, wear of the compression seal of the piston or the rod of the power hydraulic cylinder, wear of the mounting spools, the appearance of shells on the bypass valve that prevent the valve from closing tightly.

Does not lower, does not raise attachments

The reason is that the blockage of the distributor working lines blocks the passage of oil. Oil flow adjustment is not possible. Eliminate: disassemble and flush, and clean the lines, as well as diagnose the operation of the valves.

Attachment falls sharply down

This indicates a sharp drop in pressure in the system; in case of rupture of oil pipelines and a drop in the level of the working fluid, strong ventilation of the system. Eliminate: replace damaged pipes, check the tightness of the system connections, add oil to the required level.

Automatic neutralization does not work when the hydraulic cylinder is fully raised or lowered

The reason is a malfunction of the ball valve “spool position lock self-closing”. Delete; disassemble, replace worn valve parts and seals.

Diagnostics

The distributor is checked after checking the operability of the sheh hydraulic pump of the system at the rated engine speed, setting the amount of working fluid issued in liters per minute of operation. The device KI 5473 is connected to the working outputs of the unit instead of the hydraulic cylinder. Rotate the mounting lever to the "lift" position. If the value drops by more than 5 liters per minute, the dealer leaves for repair.

The device for diagnostics of the hydrodistributor.

Connection of the hydrodistributor

On MTZ 82 (80), the block is located on the front wall inside the cabin under the dashboard. The control levers are connected to the spools through the axis, and the rods are articulated to the right side of the panel. The design of the distributor allows, when moving the unit to another place or installing it on other models of tractors, to change the location of the levers by reinstalling the cover with outlets for the levers on the other side of the distributor housing. For easy connection to hydraulics and hydraulic equipment, the end sections of the unit have redundant front and side outlets for lifting and lowering. In addition, simultaneous connection to two spool outlets allows simultaneous control of two hydraulic cylinders.

The threaded holes, marked with the letter "P", connect the pipes intended for the lifting cavity of the hydraulic cylinder, the other holes connect the pipes connecting the lowering cavity.

For a hermetic connection of pipes, fittings are sealed with copper washers and rubber rings - cable glands. As a standard, one distributor spool is connected to the power hydraulic cylinder of the tractor rear linkage, and two spools are used to drive remote hydraulic equipment.

In the absence of three sections of the distributor for hydraulic drive and equipment control, an additional distributor is installed on the tractor. There are two connection methods: serial connection and parallel connection.

In the first case, the supply of the second hydraulic distributor is carried out from one of the sections of the main distributor connecting the elevator outlet with the discharge channel of the second distributor. The return flow outlet of the working fluid, used by the spool of the main assembly for additional supply of the distributor, is closed with a plug. The drain cavity of the second distributor is also connected to the hydraulic tank of the system. The valve is activated by placing the connected spool in the "lift" position. Thus, five controlled work streams are obtained for turning on the hydraulic equipment. The disadvantage is the loss of the working area and the dependence of the performance of the second distributor on the technical condition of the first node.

Parallel connection is made by installing a three-way hydraulic tee in the high pressure line from the pump. The valve divides the total flow of the working fluid into two flows to connect two units and allows you to change the oil flow. When switching from one distributor to another, the oil consumption is changed accordingly by a tap. The drain pipes coming from the distributors are connected with a tee. If the tractor uses a power regulator, a distributor is connected to the regulator. The second channel for controlling the bypass valve of the additional distributor is clogged with a plug. Thus, the system receives six working processes, three of which work with the power regulator.

Depending on the location of the hydraulic equipment, an additional manifold is placed on the rear wall of the cab or on the front right wall instead of the lower viewing window. The assembly is moved outside the cab, the levers are moved inside.

It should also be noted that this type of distributor and its modifications can be used as part of the hydraulic systems of YuMZ-6, DT-75, T-40, T-150 tractors and their modifications.

In the latest modifications of MTZ 82 (80), analogues of the mentioned brand of monoblock assembly P80-3 / 4-222 with power regulation and P80-3 / 1-222 without regulation are installed.

Multi-section distributor with joysticks.

Other brands and designs of distributors are selected when equipped with additional tractor hydraulic systems, taking into account the type of work performed, the purpose and number of attachment hydraulic drives. So, when using hydraulic equipment with a large number of hydraulic units, multi-section distributors are used. The reel control design uses joystick levers that allow you to control two reels at the same time, increasing driver productivity and workplace ergonomics.

The R-80 hydraulic distributor for the MTZ-80 tractor - device, purpose and possible malfunctions

MTZ 80 is a universal wheeled row-crop tractor, which has been produced at the Minsk Tractor Plant since 1974. The long term of production of this machine is guaranteed by a successful design and the possibility of retrofitting a large number of equipment with additional multifunctional special tractors. The joint use of various equipment is due to the high-quality, reliable and high-performance hydraulic system of the agricultural unit. One of the key elements of this system is the R-80 hydraulic distributor for the MTZ 80 tractor.

In addition, the features of MTZ 80 include:

- the presence of rear-wheel drive;

- front placement of the power unit;

- a large number of forward and reverse gears (18/4);

- ease of repair and maintenance.

The successful design of the tractor, its technical characteristics and versatility ensure the widespread use of MTZ 80 not only in agriculture, but also in manufacturing, construction, housing and communal services and forestry.

Purpose and general arrangement of the MTZ hydraulic system

The hydraulic system of the tractor is designed to control and supply power to various installed additional equipment, which can be equipped with MTZ 80. It is made in a separate-aggregate version and includes the following main elements:

- gear pump;

- power regulator;

- hydraulic booster;

- cylinders with separate control;

- hydrodistributor MTZ;

- articulated mechanism for attaching equipment;

- power take-off;

- high pressure pipes;

- connection accessories;

- oil tank.

Despite the large number of elements and assemblies used in the hydraulic system, the design, over several decades of operation, made it possible to identify emerging shortcomings in operation and, as a result of the improvements made, eliminate them.

At present, the operation of the hydraulic system is characterized by high reliability and high performance, which allows the use of the most modern mounted and trailed equipment for the MTZ 80 tractor. An important contribution to this is made by the P80 hydraulic distributor, which, with proper maintenance and proper adjustment, requires practically no repair.

The need for a hydraulic distributor on a tractor

Distributor R-80 3/1 222G of a three-section type is used in the general-purpose hydraulic system of the Belarus 80 tractor and performs the following functions:

- protects the system from hydraulic overloads during forced lifting or lowering;

- distributes the flow of the working fluid pumped by the hydraulic pump between the nodes of the system (hydraulic cylinders, hydraulic motors, etc.);

- flushes the system at idle with a neutral output when gear oil enters the oil tank;

- connects the working volume of the hydraulic cylinder with the drain of the process fluid (when operating in the neutral position).

In addition, the P80 3/1 222G hydraulic distributor serves as the basic device on which various modifications are made for use in loading units, excavators and road construction equipment.

Technical characteristics and parameters of the distributor can be found in the description of the P80 brand, where:

- R - distributor.

- 80 - nominal transmission fluid flow (l / min).

- 3 - version for process pressure (maximum allowable 20 MPa, nominal 16 MPa).

- 1 - type of operational purpose (autonomous use in general-purpose hydraulic systems).

- 222 - three special drums, made according to the second version.

- G - hydraulic locks (check valves).

Mechanism and functioning of the hydraulic distributor MTZ 80

The hydraulic distributor device consists of the following main parts:

- cases P80 3/1 222G with fittings for valves and channels for supplying process fluid from a gear pump and channels for draining oil from cylinders;

- three drums equipped with locking and automatic return mechanisms;

- top case cover with built-in spool guides;

- special safety valve.

The principle of operation of the hydraulic distributor is based on the fact that when the hydraulic distributor R80 3/1 222G is connected to the hydraulic system inside the body, all spools and the valve form several combined channels for the passage of hydraulic fluid. There are three in total.

- Flushing - closes all spools and bypass valve.

- Drain - with this option, only the spools are connected and this channel ensures the release of residual liquid.

- Control: It also passes through all spools and bypass valve, but is connected to the process piping from the pump.

The control of the spools, respectively, and the redirection of the transmission oil flows through the corresponding channels provide four different positions when working with additional units and equipment. These modes of operation include:

- neutral,

- increase,

- overcast weather,

- floating position (lowering of the working bodies under the action of its own weight).

Such a device allows, if necessary, to carry out repairs separately for each operating mode and P80 connection scheme.

Possible malfunctions of the hydrodistributor

The most common malfunctions of the P80 3/1 222G hydraulic distributor installed on the MTZ 80 tractor include:

- wear of the interface in the body-spool of the binomial hydraulic valve;

- violations in the piston of the hydraulic cylinder;

- breakdown of pump gears;

- cracking rubber stamps;

- leakage of hydraulic fluid through the connecting fittings;

- damage to oil lines.

The design and arrangement of the hydraulic distributor allows the machine operator to fix these malfunctions with his own hands. In addition, a special repair kit recommended by the manufacturer for P80 3/1 222G will help facilitate repairs.

The reliable and proven design of the P80 hydraulic distributor allows it to be successfully used on a newer version of the Belarus 920 tractor, as well as on the MTZ 3022 multifunctional.

Hydrodistributor Р80-3/1-222

The dealer applies for

- Tractors: YuMZ-6, YuMZ-650, YuMZ-652, YuMZ-8080, YuMZ-8280, YuMZ-8070, YuMZ-8270, T-150, KhTZ-153, KhTZ-180, KhTZ-181, MTZ-80, KhTZ-17021, KhTZ-17221, KhTZ-17321, K-710, T-250, T-4, LT-157, MTZ-XA, TB-1, LD-30, LT-157, DM-15, Hydrodistributor MTZ -80, distributor MTZ-82, MTZ-800, MTZ-820, MTZ-900, MTZ-920, DT-75, VT-100, LTZ-55, LT-72, T-40, T-50, T-60, LTZ-155, T-70, K-703

- Excavators: EO-2621

- Chargers: PEA-1,0, PG-0,2, K-701

- Forestry equipment: TDT-55, LHT-55, LHT-100, TLT-100

P80 distributor marking

An example of marking (technical characteristics) of the R80-3/4-222G hydraulic valve:

- R is a dealer;

- 80 - declared productivity, l / min;

- 3 - pressure (nominal - 16 MPa, limit - 20 MPa);

- 4 – destination code;

- 222 - the number of turns and their type, in this case - three turns of type 2;

- G - with water seals (if absent - without them). Devices with and without a water seal are completely interchangeable.

The principle of operation of all hydraulic valves P 80 is identical, the price in the price list depends on the type of product (before buying, see the brand).