So, war! Tesla: cylindrical elements only, 4680. Volkswagen: uniform rectangular elements

Content

During Battery Day in October 2020, Tesla announced the creation of a new cylindrical cell format, the 4680, which will soon appear in the vehicle lineup. Six months later, Volkswagen announced the standard cuboid links that would become the basis for almost the entire group, including trucks.

Volkswagen is catching up, creating a slip of only 2-3 years compared to Tesla

Table of contents

- Volkswagen is catching up, creating a slip of only 2-3 years compared to Tesla

- What does all this mean for the average audience?

There are three types of cells currently used in electric vehicles:

- cylindrical (cylindrical shape) mainly used by Tesla,

- rectangular (English prismatic), probably the most common among traditional manufacturers, he decided to do it Concern Volkswagen inside the "single cell",

- bag (pouch), which appear where the most important thing is to “squeeze out” as much battery capacity as possible from a given capacity.

Each of these types has advantages and disadvantages: cylindrical were once the most popular (used in cameras and laptops), so Tesla and Panasonic specialized in them. They also guarantee a high level of security. Sachet they allow high energy densities to be achieved, but designers must remember that they can significantly increase the volume as they do not have openings to release any possible gases. Cuboids these are the contents of bags in a hard case, the easiest way to assemble them (for example, from blocks) is a ready-made battery, moreover, they are mechanically stronger.

Volkswagen already uses rectangular cells, but it seems that their format is at least partially adapted to the design of the car. Unified cells should appear for the first time in 2023, and in 2030 they should account for up to 80 percent of all used cells:

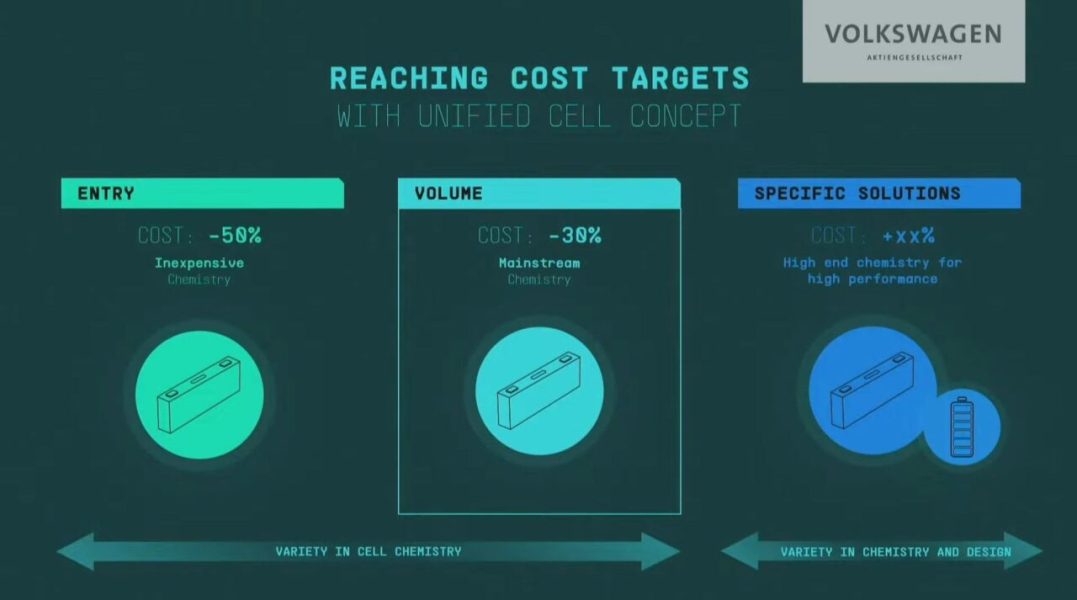

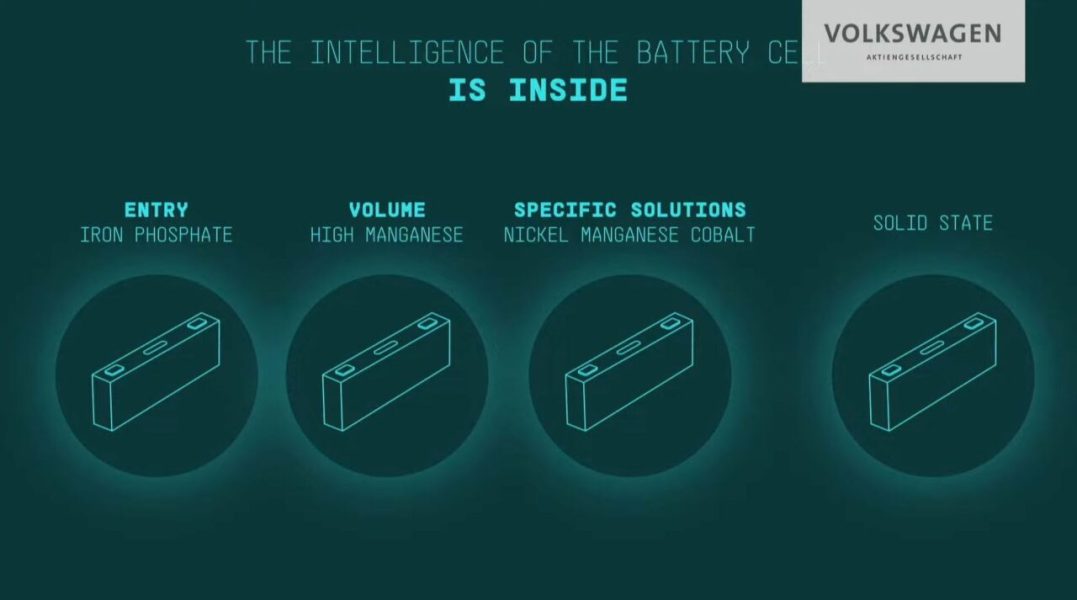

New cells will not be organized into modules (from cell to packaging), and the same format (form) must contain different types of chemistry inside:

- in the cheapest cars they will it LFP cells (lithium iron phosphate)

- with bulk products will apply cells high in manganese (and some nickel)

- on selected models появляется NMC cells (nickel-manganese-cobalt cathodes),

- ... and in addition to them, Volkswagen also remembers solid electrolyte cells, as it owns 25% of the shares of QuantumScape. Solid-state cells already allow a 30% increase in range and a charge in 12 minutes instead of 20 (data based on prototypes):

As for the anode, the company does not make any preconceptions, but today it is testing graphite with silicon. Now curiosity: Porsche Taycan and Audi e-tron GT have silicon anodesthanks to which they can be charged with such a high power (currently: up to 270 kW).

Ultimately Volkswagen wants to use links as structural elements of a car (cell to machine) and it looks like standardized cells will be adapted for that. However, before the Group reaches this stage, it must go through this stage. battery without modules (cell-to-pack) - the first machine built in this way will be model created by the Artemis Audi project... It is possible that we will see a conceptual version of this car already in 2021.

Modular battery. His skeleton is links. The next step is links that are not ballast, but a structural element of the car - Volkswagen cell-to-car (c)

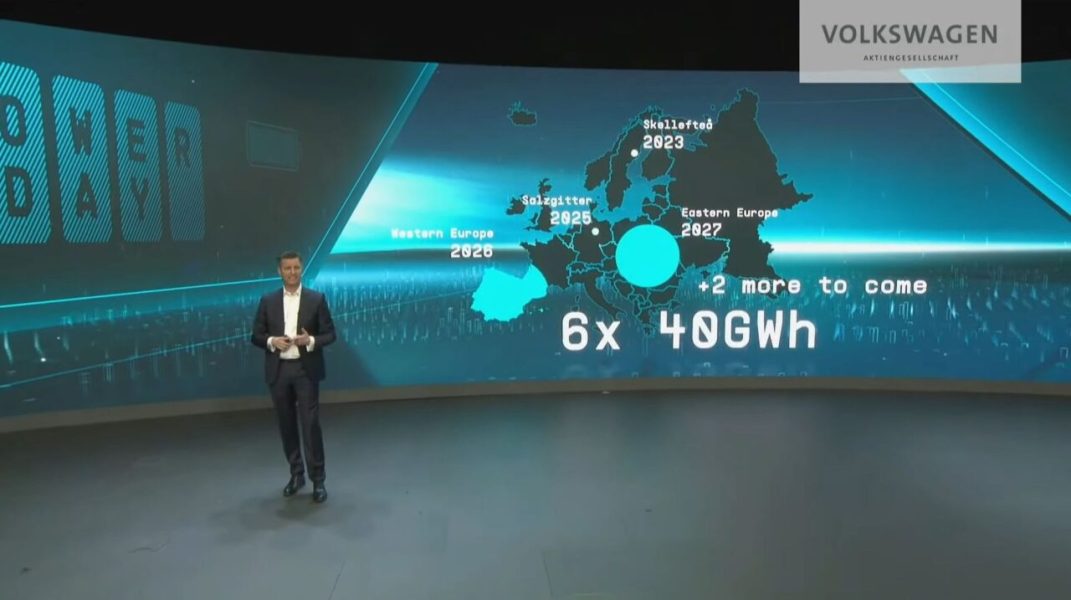

The new elements are likely to be produced in all 6 factories that Volkswagen wants to launch by 2030. (some with partners). The first one built by Northvolt will be built in Skelleftea, Sweden. The second one is in Salzgitter (Germany, since 2025). The third will be in Spain, Portugal or France (from 2026). In 2027, a plant in Eastern Europe should be launched, including Poland., Czech Republic and Slovakia accepted – no decision yet. It is also unknown where the last two plants will be built.

What does all this mean for the average audience?

From our point of view the key advantage of unified cells is the reduction in production costs... Since they will be universal, the automatics configured in the same way will be able to work at all plants of the concern. One research laboratory is enough for one type of chemistry. It's all maybe transfer to lower prices for electric vehicles.

And even if that doesn't happen, Tesla, Volkswagen, Audi and Skoda could put price pressure on the rest of the market. Because using external suppliers (see Hyundai, BMW, Daimler,…) always means less flexibility and higher costs.

Opening photo: unified link of Volkswagen prototype (c) Volkswagen

This may interest you: