What is the undercarriage of a car

The undercarriage of a motor vehicle includes a number of components and mechanisms that together ensure the movement of the vehicle relative to the road and reduce phenomena such as shaking, vibrations and rocking to the desired level. It is from the chassis that the level of comfort during the ride for the driver and passengers largely depends.

Three major components of a running car can be distinguished:

- bearing base (skeleton);

- mover (not to be confused with the engine!);

- suspension.

Let us consider in more detail the device and the functional purpose of each of these components.

A frame or a body can serve as a supporting element. In cargo vehicles, the role of the skeleton is usually performed by the frame. In passenger cars, the carrier is the body, the design of which can be frame or frameless. The use of the frame allows you to further reduce the level of vibrations in the cabin and increase comfort. On the other hand, the frameless body has a lower weight, which has a positive effect on the driving performance and economy of the car.

The body of a passenger car can have up to three functional compartments - the engine compartment, the passenger compartment and the trunk. In many models, the trunk as a separate compartment is missing. And It happens that all three departments are combined into one volume.

In the general case, a mover is a converter of a certain type of energy into work to move. The propeller can be a sail, oars, a propeller or propeller, jet engine nozzles, an electromagnetic field, and much more. In land transport, wheels or tracks are usually used as a mover, less often - other devices, for example, walking mechanisms.

Cars and most trucks use pneumatic wheels, which consist of a rim, disc and tire. Discless wheels are installed on buses and heavy vehicles.

Discs

For passenger cars, non-separable disks are usually used. In this design, the rim is spot welded to the disc. Disks with a removable rim are found in off-road vehicles. It happens that cutouts are made in the discs to reduce their weight and improve the cooling of the brake mechanisms.

Wheels are made from light alloys based on aluminum or magnesium or from steel. Most of the cars coming off the factory conveyors are completed with steel disks. They are distinguished by low cost and ductility - upon impact, they do not crack, but deform and at the same time play the role of a damper for suspension and steering parts, reducing the likelihood of their defects. In many cases, a deformed steel disc can be repaired. The disadvantages of steel discs include a significant mass and susceptibility to corrosion.

Alloy wheels are made by casting or forging. Alloy wheels reduce the weight of the wheels and generally reduce unsprung weight, which leads to a reduction in the load on the suspension and favorably affects the ride, stability and control of the car. However, alloy wheels are inferior in strength to steel wheels; with a strong impact, they can crack and collapse. This is especially true for magnesium discs, which, moreover, are not distinguished by high anti-corrosion properties.

Forged wheels made of light alloys have the smallest mass, they are distinguished by high strength and resistance to corrosion. Their widespread use is constrained by the complexity of manufacturing and high cost.

Seat for the tire - rim shelf. For tube tires, it has a slope of a set of degrees relative to the horizontal plane; in the design for tubeless tires, the shelf angle is approximately 15 degrees. The mounting diameter of the disc is determined by the level of the shelves.

On the sides of the rim there are stops for the tire beads - the so-called flanges, the distance between them corresponds to the width of the rim. This size should normally be 70 ... 75% of the width of the tire profile. Deviation to one side or the other will degrade the driving performance of the vehicle.

Another important parameter of the disc is the offset - the distance between its vertical plane of symmetry and the plane of contact with the hub. Departure must be within the limits recommended by the automaker, otherwise handling will deteriorate, especially when braking.

In addition to the rim width, diameter and offset, when choosing rims, you need to consider the size of the central hole, as well as the number, location and diameter of the mounting holes.

In the online store you can choose rims for cars of Chinese brands. You can also purchase it here.

Tires

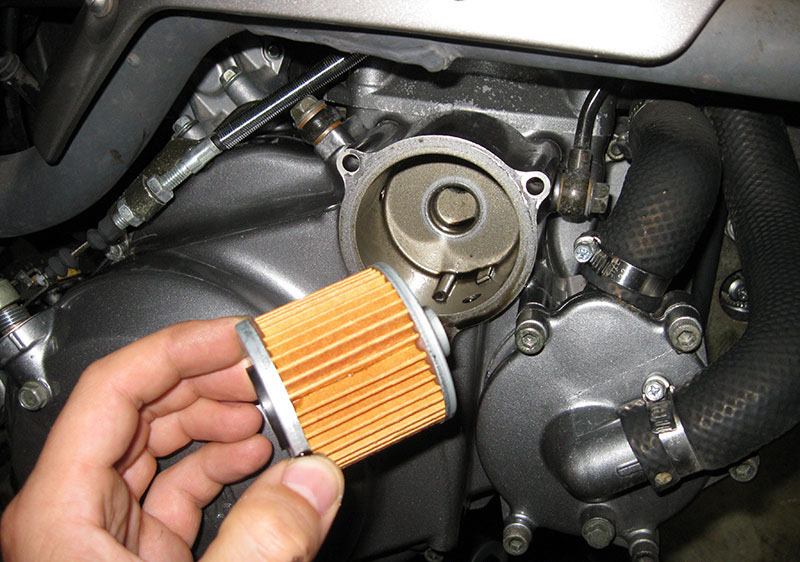

Tires provide the right grip on the road surface and minimize the effect of road bumps on the suspension and bodywork. Impact smoothing occurs due to the elasticity of rubber and the elastic properties of the compressed gas inside the tire. As a rule, ordinary air is pumped into the tire, it happens that nitrogen. You can read about whether it is worth inflating tires with nitrogen in the corresponding one.

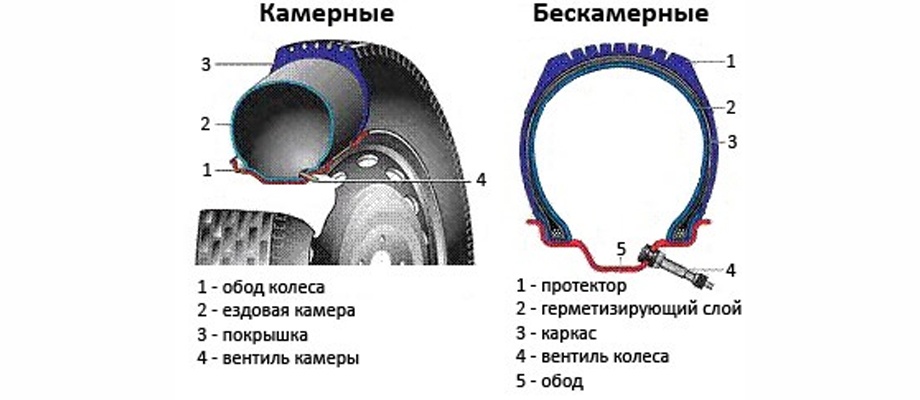

According to the method of sealing tires are divided into chamber and tubeless. The tube tire consists of an air-filled rubber chamber and a tire. The chamber has a valve that leads out through a hole in the rim. This design is still occasionally found, but is already outdated and doomed to complete disappearance in the foreseeable future.

Almost all cars produced in our time are equipped with tubeless tires that have a special layer on their inner surface that ensures tightness and prevents leakage of compressed air through the micropores of the tire. The beads of such tires have seals to seal in the seating area on the rim flanges. The valves are mounted in special holes in the rim.

Tubeless tires are lighter, more reliable and more durable than tube tires. However, they must be removed and installed carefully. If the sidewall of the rim is damaged, the sealing of the tire may be compromised. It is better to use the services of a tire shop, which has the appropriate equipment.

For the manufacture of tires, rubber and cord (metal, polymer or textile) are used. Depending on the location of the cord threads, there are tires with a diagonal and radial carcass. In passenger cars, radial tires are mainly used, which have a number of advantages compared to diagonal ones.

Tires also differ in weather conditions of use, profile, size, tread pattern, speed index, load capacity and a number of other parameters. You can read more about how to choose the right tires for your car. A separate one is devoted to the choice of winter tires.

Purpose and varieties

The suspension is an intermediate link between the wheels and the carrier frame. Its main functional purpose is to mitigate the negative impact of impacts on the unevenness of the roadway, dampen the resulting vibrations of the body and ensure the smooth movement of the vehicle. Thanks to the suspension, the connection between the body and the wheels becomes elastic, the internal combustion engine, gearbox and other components are less subject to shaking, and people in the cabin feel quite comfortable. A well-maintained and properly functioning suspension improves vehicle handling and improves driving stability.

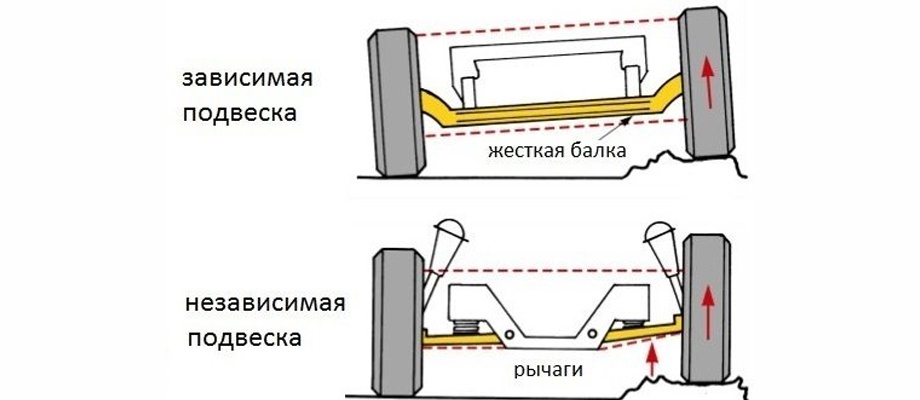

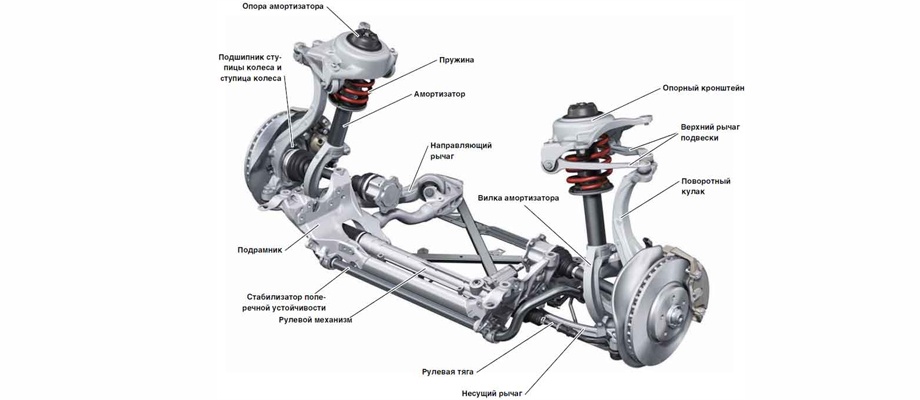

Usually there are two main types of suspensions - dependent and independent. In a dependent, two wheels of one axle are connected to each other and are displaced in space along with the axle. As a result, if one of the wheels hits, for example, a lift and tilts, the other wheel of the same axle will tilt by the same angle. An independent one does not have such a rigid connection, the wheels can tilt, rise and fall independently of one another.

You can read about the advantages and disadvantages of dependent and independent suspension and which one is better in this.

In passenger cars, dependent suspension is found only on the rear axle. On the front, only an independent suspension is installed. The MacPherson system is the most widely used, due to the relative simplicity of design and low cost with fairly good kinematic properties. MacPherson also has a small weight, which is very important, since the suspensions are unsprung masses, and the lower the ratio of the total unsprung and sprung mass of the car, the better its driving performance - handling, ride and partly dynamics.

In expensive models, a more efficient multi-link suspension is used.

There are other varieties of independent suspension - trailing arms, double wishbones, oblique arms, leaf springs, torsion bars - but for various reasons they are of limited use.

Design

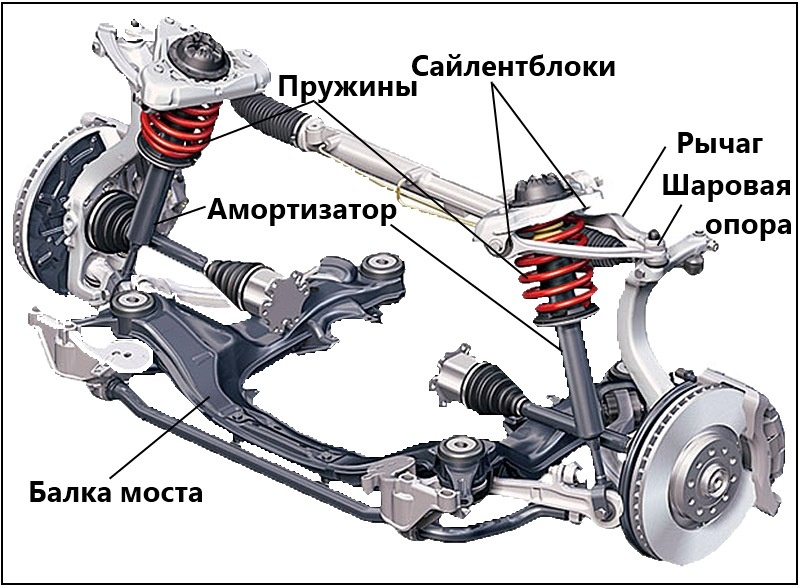

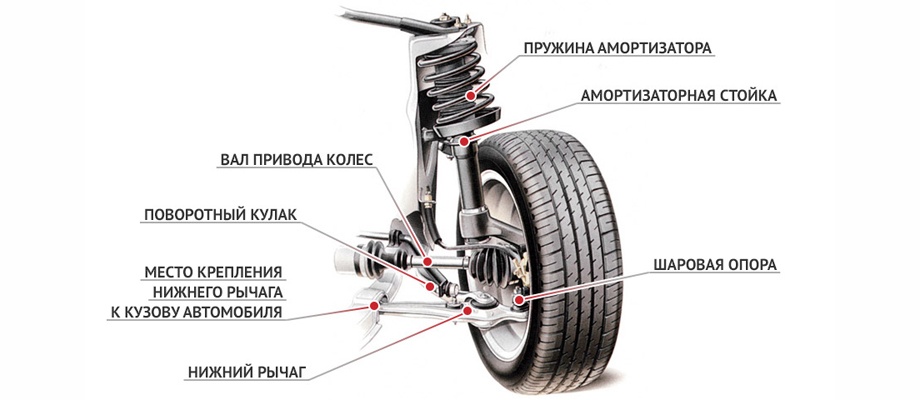

Any suspension includes three main types of components - guides, elastic and damping.

The guide elements are levers, rods, rods. The number of levers can be different, and they can be located along, across or at an angle to the longitudinal axis of the car. Read more about the device and types of suspension arms.

Thanks to elastic elements - springs, springs, torsion bars, air bags - driving a car is fundamentally different from driving a cart. Their use allows you to feel quite comfortable even while driving on the road of not the best quality.

At the same time, the elastic elements cause strong rocking in both the horizontal and vertical planes. Without effective damping of such vibrations, driving a car normally is almost impossible and even unsafe. Telescopic shock absorbers act as a damper. In the old days, lever shock absorbers were widely used, but now they can only be found in a museum.

The principle of operation of a telescopic hydraulic shock absorber is based on the resistance of a liquid (oil) when it is forced through holes of small diameter. The design of a two-tube shock absorber consists of a cylinder located inside a cylindrical body, a piston with a rod, a compression valve and a compensation valve. When the suspension is moved vertically down, the piston forces oil through a plate with holes from one tube to another. The viscosity of the oil determines the inertia of the flow, in other words, the compression will be slow. Fluid from the cavity below the piston will flow into the cavity above it. When the piston returns up, a similar process will take place in the opposite direction.

There are also single-tube shock absorbers that use gas pumped under high pressure. You can read about how to diagnose the health of shock absorbers.

All elements of the running gear work in a stressful mode, suspensions periodically experience especially heavy loads. Therefore, it happens that even very reliable parts can fail. About what signs indicate possible problems with the chassis, read this.

If there is a need to purchase spare parts, this can be done in the online store. There is a wide selection of different manufacturers, and other suspension parts. You can also select spare parts for other components and systems of your car.