What is a scraper blade made of?

Content

Wolfram carbide

Tungsten carbide is a compound composed of 50% tungsten and 50% carbon. There are several methods used to form the compound, the most common of which is the interaction of metallic tungsten with carbon at temperatures from 1400 to 2000°C. degrees Celsius.High speed steels

High speed steel (HSS) is an alloy that combines steel (iron and carbon) with other elements such as chromium, molybdenum, tungsten, vanadium or cobalt. Elements other than steel can make up to 20% of the HSS composition, but always exceed 7%.

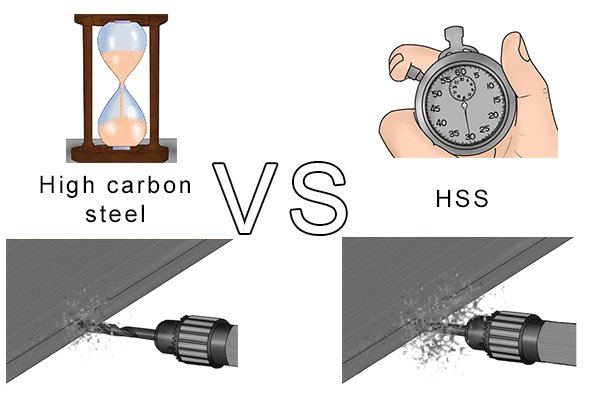

High speed steel (HSS) is an alloy that combines steel (iron and carbon) with other elements such as chromium, molybdenum, tungsten, vanadium or cobalt. Elements other than steel can make up to 20% of the HSS composition, but always exceed 7%.Adding these elements to steel does not in itself create HSS, the material must also be heat treated and tempered.

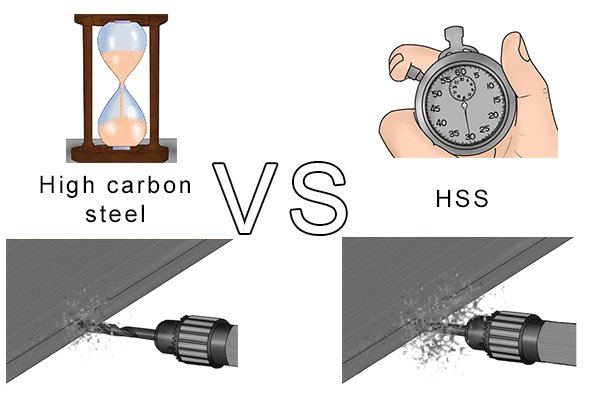

High speed steel (HSS) is able to cut material faster than high carbon steel, hence the name "high speed". This is due to its greater hardness and abrasion resistance compared to high carbon and other tool steels.

High speed steel (HSS) is able to cut material faster than high carbon steel, hence the name "high speed". This is due to its greater hardness and abrasion resistance compared to high carbon and other tool steels.

Why are high speed steel and carbide used for scraper blades?

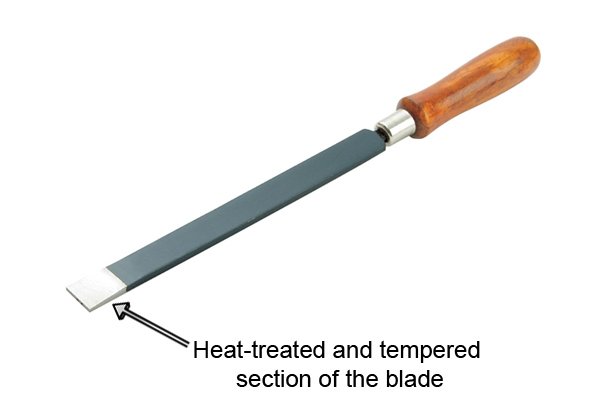

The scraper blade must be made of a harder material than the object it is scraping to be effective. Additional alloying elements and manufacturing processes, such as the heat treatment that high speed steel is subjected to, give it the hardness needed for scraping.

Carbide scrapers are harder than HSS. This allows them to be used on an even wider range of materials.

Non-replaceable scraper blades

Non-replaceable scraper blades are almost always made of high speed steel, since the cost of making the entire blade and shaft out of carbide would be too high.

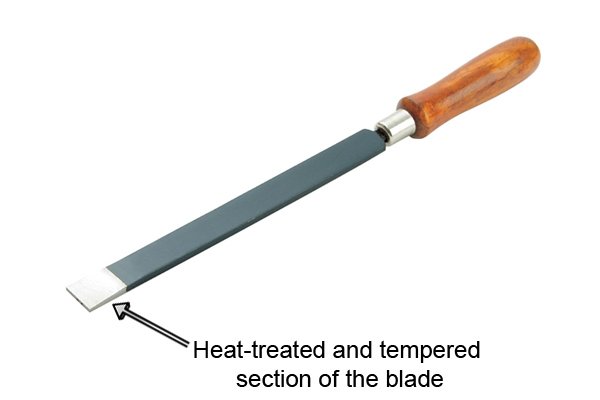

Non-replaceable scraper blades are almost always made of high speed steel, since the cost of making the entire blade and shaft out of carbide would be too high.While the non-replaceable scraper blades are made of high speed steel, only a small portion at the end of the scraper is heat treated and tempered. The heat treated and tempered area often differs in color from the rest of the shaft.

What materials can scraper blades be used on?