Wear of brake pads, discs and drums (reasons for rapid wear of parts of the brake system)

Content

Wear parts in the brake system of a car, and these are discs, drums and pads that are not subject to scheduled replacement due to their unpredictable resource. It all depends on the traffic situation, the habits of the driver and the quality of the materials. Therefore, it is vital to evaluate the condition of parts with strict periodicity in order to fix a critical change in control dimensions in time.

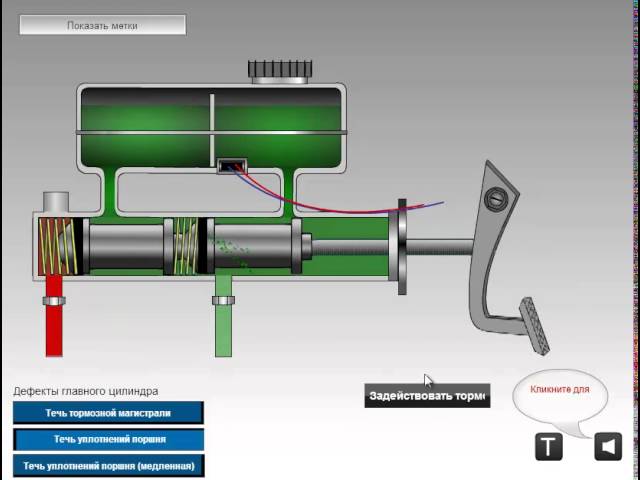

The principle of operation of the braking system in the car

The general principle of the brakes is the organization of friction between parts rigidly connected to the suspension elements and parts that rotate with the wheels.

The occurrence of this force extinguishes the energy of a moving car, reducing speed.

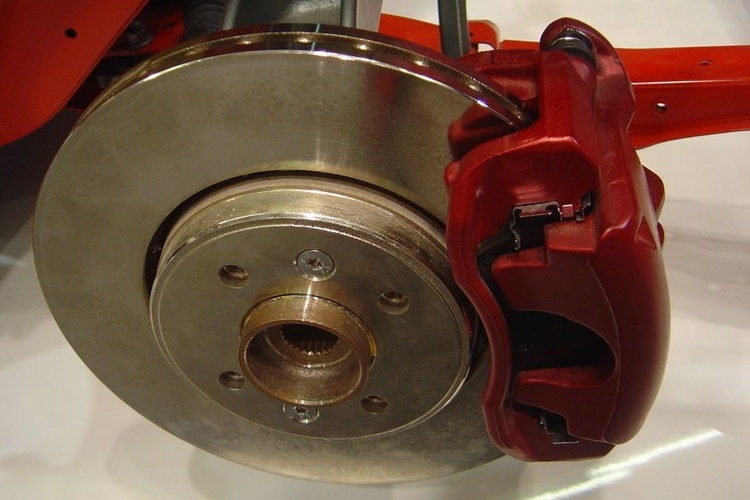

Disc Brakes

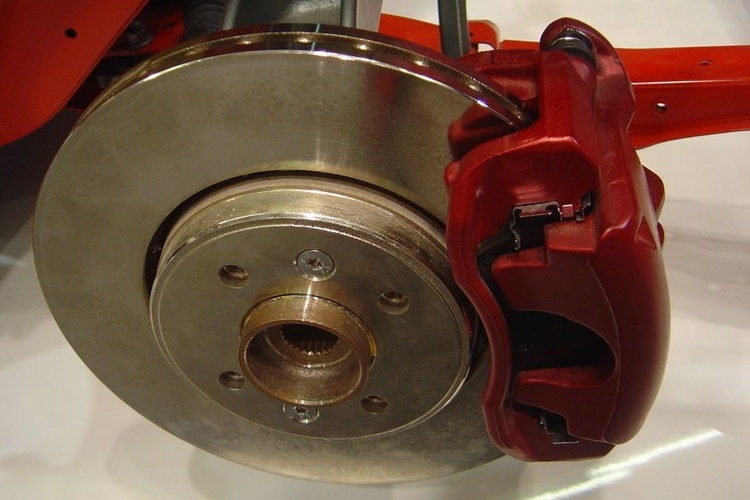

The disc-type brake mechanism consists of a caliper attached to the suspension arms through other parts, rotating coaxially with the disc wheel hub and brake pads.

With an increase in pressure in the hydraulic brake cylinders that make up the caliper, their pistons begin to move, shifting the pads that cover the disc on both sides. The pad area is several times smaller than the lateral area of the disc, that is, they capture only a small sector of it.

The number of cylinders in the caliper may vary, depending on the required brake efficiency and other reasons, but there are always two pads moving towards each other.

Their preload is provided either by counter-operating cylinders, or by the so-called floating type bracket, when there is no need for a second cylinder.

Scheme of operation of a caliper with a floating structure:

- 1 - bracket.

- 2 - guide.

- 3 - sealing ring.

- 4 - caliper with a cylinder.

- 5 - piston.

- 6 - cuff.

- 7 - pads.

- 8 - brake disc.

- 9 - brake fluid.

- 10 - fitting.

Caliper with fixed design:

- 2 - mounting bolts.

- 4 - caliper with cylinders.

- 5 - pistons.

- 6 - sealing cuffs.

- 7 - pads.

- 8 - brake disc.

- 9 - brake fluid.

- 10 - fitting.

The disc brake has several advantages that have ensured its use in the vast majority of cars:

- High thermal efficiency, as the disk is almost completely open and available for cooling by outside air.

- Simplicity and compact design.

- Ease of monitoring the condition of the wear surfaces of pads and discs.

- Possibility of using additional ventilation with the help of the internal structure of the disc and its perforation.

- Low sensitivity to dirt and ingress of moisture due to good conditions for self-cleaning.

The material for discs is usually cast iron, which has satisfactory frictional properties and their stability, less often steel, and for sports applications, composite materials are used that allow operation at high temperatures without loss of strength and geometry.

Watch this video on YouTube

The pads consist of a steel substrate, on which friction linings made of a material selected by many years of research are fixed with special glue and molded spikes.

The difficulty here lies in the compromise between numerous conflicting properties, high coefficient of friction on cast iron and steel, wear resistance, the ability to protect discs from wear, temperature stability and a minimum level of acoustic noise.

Drum brakes

They include brake drums in the form of cylinders closed on one side and brake pads working on their inner surface.

The working hydraulic cylinders are also inside; when you press the pedal, they push the pads apart, pressing them against the drums. The pad area is only slightly smaller than the inner cylindrical surface.

The use of such mechanisms is limited, due to some fundamental shortcomings:

- cooling imperfections, pads work in a closed cavity;

- poor resistance of the linings when water gets inside the brake;

- significant dimensions and weight of the entire structure.

At the same time, the drums have their own advantages, in particular resistance to contamination, long service life and technological ease of manufacture.

Why brake pads, discs and drums wear out

Friction, acting as the main working factor in the efficiency of brakes, has a well-defined physical essence. This is a collision between the slightest irregularities, roughness of rubbing surfaces, which does not always remain without consequences for them.

And these consequences are the sadder, the higher the coefficient of friction, that is, the faster the machine stops. We have to choose a compromise between the quality of braking and the durability of parts.

Based on many years of experience, the lining and disc materials are selected in such a way that the average disc can survive three or four sets of pads. This is the optimum in terms of the ratio of the price of a massive and expensive disc to the cost of relatively inexpensive pads, which are considered consumables.

Watch this video on YouTube

Causes of rapid wear

Reduced service life of brake friction elements is caused by several factors.

- Riding style. It is natural that with frequent use of the pedal, wear will go faster, especially if the brakes do not have time to cool.

- Deviations in the properties of materials. Not always with current replacements, discs (drums) and pads are installed exactly the same as they were at the factory. Discs can be made from cast iron of varying hardness and carbon content, and pads are made using different technologies, using traditional materials without asbestos, inclusion of metals or organic fibers. As a result, it is possible, with equal efficiency in various combinations, to change pads or discs more often.

- Dirt on work surfaces. Dust and sand work as abrasives, which accelerates wear.

- Disc corrosion and lining material degradation. They can occur both due to the rare use of the brakes, and vice versa, constant overheating.

- Malfunctions of the guide apparatus of the brake. The pads will not press evenly, causing abnormal one-sided wear.

- Wheel bearing problemswhen the backlash wheel causes constant rubbing of the pads on the disc.

- Violations in maintaining gaps. Neglect of drum brake adjustments or souring of pistons in disc brakes.

As you can see, accelerated wear can occur both for natural reasons and from the driver's inattention.

Why does uneven wear of parts appear

This is most often due to internal corrosion of the pistons and cylinders in the hydraulic drive. Especially in multi-piston mechanisms. There are also souring in the guide apparatus of the caliper.

The bracket warps, causing the pads to be pressed harder on one edge than the other. The caliper has to be disassembled, cleaned and lubricated, preventing grease from getting on the friction surfaces. But it is better to resort to replacing parts.

Watch this video on YouTube

What is the danger of wear of parts of the brake system

When the parts reach critical dimensions, the braking efficiency drops, which is not always noticeable due to the reserves built into the braking system. This is a certain deceit, the brakes can fail suddenly with irreparable consequences.

At the maximum stroke of the pads, with unacceptable wear, the pistons extend too far out of the cylinders, falling into corroded, previously unused areas. There is a high probability of jamming with an avalanche-like increase in wear and complete failure.

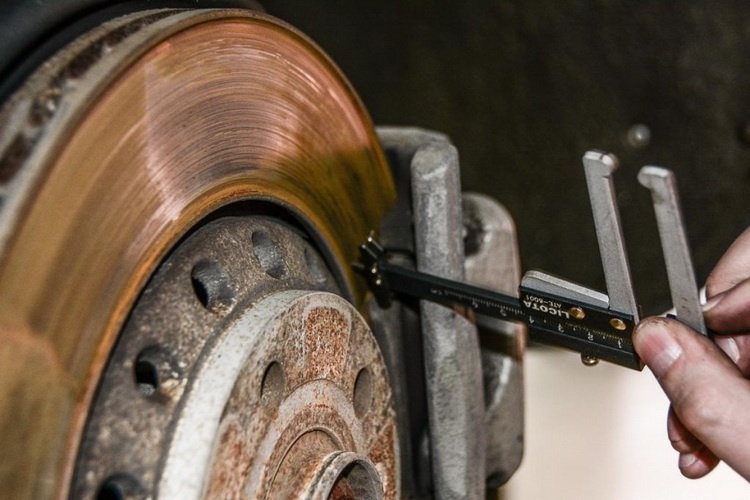

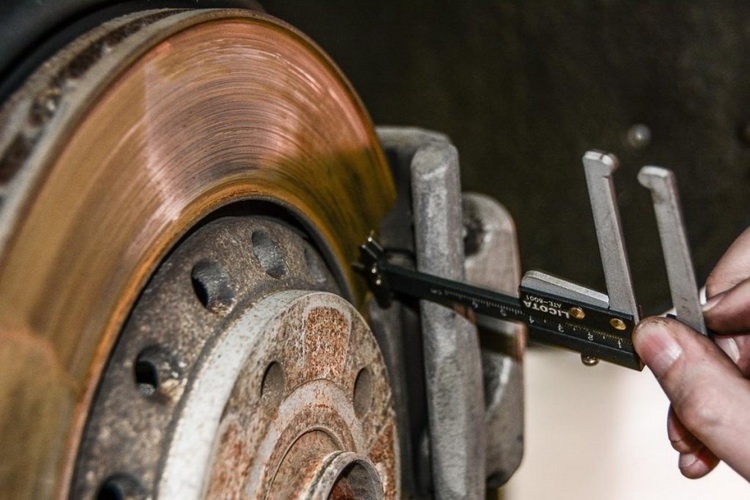

This is exacerbated by a decrease in the thickness of the disk below the allowable limit. Each car has its own minimum size standard, which must be controlled at each scheduled maintenance.

Checking the pads without removing the wheel

It is not always possible to do this without removing the wheel. The disc must have a sufficiently large distance between the spokes to provide visual control. Sometimes you need to use a mirror and a flashlight.

If we consider the zone of contact between the pad and the disc, then in good light you can see the size of the friction lining remaining on the substrate of the pad.

Usually the limit value is 2-3 mm. It's dangerous to drive any further. And it’s better not to bring it up to this value, after the remaining 4 mm it’s time to change the pads.

The issue is further complicated by the almost complete unreality of assessing the internal pad hidden under the caliper.

Even if it can be seen from the end of the disk, this will give little information, this zone wears out unevenly, and is also hidden by the edge formed during wear on the circumference of the disk. That is, with uneven wear of the pads, studying only the outer one will not give anything.

Watch this video on YouTube

Fortunately, designers usually provide an electronic or acoustic wear limit indicator. The block begins to creak characteristically or lights up the indicator on the dashboard.

Recommendations for replacing brake pads

The design of the brakes on all machines is similar, so the following features of the maintenance of the units can be distinguished.

- The pads are always changed in sets on the same axle. It is unacceptable to change them one at a time with uneven wear.

- When replacing the pads, it is necessary to lubricate their entire guide apparatus with a special high-temperature composition.

- A mandatory check is subject to the freedom of movement of the pistons in the hydraulic cylinders.

- In case of uneven wear of the disc or exceeding the limits of its geometry, the disc must be replaced unconditionally.

- When pushing the pistons under the new pads, measures must be taken to freely increase the fluid level in the master cylinder reservoir, and then bring the level to normal.

- The first time you press the pedal after installing the pads, it falls through, so you can not start moving without pressing the brake several times.

- At first, the pads will run in, so the effectiveness of the brakes will not be restored immediately.

- Rear axle drum mechanisms will require handbrake adjustment.

Watch this video on YouTube

There can be no trifles in the maintenance of the brake system. Don't hope that replacing the pads will solve all the problems.

In especially severe cases, you will have to significantly upgrade all the elements of the system, hoses, working fluid, up to replacing the calipers, no matter how expensive it is. In any case, the consequences will be more expensive.