Engine oil quality

Engine oil quality affects the normal operation of the internal combustion engine, its resource, fuel consumption, the dynamic characteristics of the car, as well as the amount of lubricating fluid leaving for waste. All indicators of the quality of engine oil can only be determined with the help of complex chemical analysis. However, the most important of them, indicating that the lubricant needs to be changed urgently, can be checked independently.

How to check the quality of the oil

There are a number of simple recommendations by which you can determine a new good quality oil.

The appearance of the canister and the labels on it

Currently, in stores, along with licensed oils, there are many fakes. And this applies to almost all lubricants belonging to the middle and higher price range (for example, Mobile, Rosneft, Shell, Castrol, Gazpromneft, Total, Liquid Moli, Lukoil and others). Their manufacturers are trying to protect their products as much as possible. The latest trend is online verification using codes, a QR code, or post-acquisition of the manufacturer's website. There is no universal recommendation in this case, since any manufacturer solves this problem in its own way.

However, for sure, when buying, you need to check the quality of the canister and the labels on it. Naturally, it should contain operational information about the oil poured into the canister (viscosity, API and ACEA standards, auto manufacturer approvals, and so on).

Engine oil marking

a detailed explanation of all markings on a canister of motor oil. Find out what the markings of engine oils API, SAE, ACEA, ILSAC and GOST mean in order to choose the required oil for the internal combustion engine of a car Read more

If the font on the label is of low quality, it is pasted at an angle, it is easily peeled off, then most likely you have a counterfeit, and accordingly. it is better to refrain from buying.

Determination of mechanical impurities

Engine oil quality control can be done with a magnet and/or two glass plates. To do this, you need to take a small amount (about 20 ... 30 grams) of the tested oil, and place an ordinary small magnet in it, and let it stand for several minutes. If the oil contains a lot of ferromagnetic particles, then most of them will stick to the magnet. They can be seen visually or touch the magnet to the touch. If there is a lot of such garbage, then such oil is of poor quality and it is better not to use it.

Another test method in this case is with glass plates. To check, you need to place 2 ... 3 drops of oil on one glass, and then grind it over the surface with the help of the second. If during the grinding process a metallic creak or crunch is heard, and even more so, mechanical impurities are felt, then also refuse to use it.

Oil quality control on paper

Also, one of the simplest tests is to place a sheet of clean paper at an angle of 30 ... 45 ° and drop a couple of drops of the test oil on it. Part of it will be absorbed into the paper, and the rest of the volume will spread over the paper surface. This trail needs to be looked at closely.

The oil should not be very thick and extremely dark (like tar or tar). The trace should not show small black dots, which are metal domes. there should also be no separate dark spots, the oil trace should be uniform.

If the oil has a dark color, but at the same time it is quite liquid and clean, then most likely it can also be used, and it is of quite good quality. The fact is that any oil, when it enters the internal combustion engine, literally starts to darken after a run of several tens of kilometers, and this is normal.

Tests at home

it is also possible to carry out tests with a small amount of purchased oil, especially if for some reason you doubt its quality. For example, a small amount (100 ... 150 grams) is placed in a glass beaker or flask and left for a couple of days. If the oil is of poor quality, then it is likely that it will delaminate into fractions. That is, at the bottom there will be its heavy parts, and on top - light ones. Naturally, you should not use such oil for internal combustion engines.

also a small amount of butter can be frozen in the freezer or outside, provided that there is a very low temperature. This will give a rough idea of the low temperature performance. This is especially true for cheap (or fake) oils.

All-weather oils are sometimes heated in a crucible on an electric stove or in an oven at a constant temperature close to 100 degrees Celsius. Such experiments make it possible to judge how quickly the oil burns out, and also whether it separates into the fractions mentioned above.

Viscosity at home can be checked using a funnel with a thin neck (about 1-2 mm). To do this, you need to take the same amount of new (with the same declared viscosity) oil and lubricant from the crankcase. And pour each oil in turn into a DRY funnel. With the help of a clock (stopwatch), you can easily calculate how many drops of one and the second oil will drip in the same period of time. If these values \uXNUMXb\uXNUMXbare very different, then it is advisable to replace the oil in the crankcase. However, this decision needs to be made on the basis of other analytical data.

An indirect confirmation of the failure of the oil is its burnt smell. Especially if it contains a lot of impurities. When such an aspect is identified, then additional checks must be carried out, and if necessary, replace the lubricant. also, an unpleasant burning smell may appear in the event of a low oil level in the crankcase, so check this indicator in parallel.

also one "home" test. The algorithm for its implementation is as follows:

- warm up the internal combustion engine to operating temperature (or skip this step if it has already been done);

- turn off the engine and open the hood;

- take a rag, take out the dipstick and gently wipe it dry;

- re-insert the probe into its mounting hole and remove it from there;

- visually assess how an oil drop is formed on the dipstick and whether it is formed at all.

If the drop has an average density (and not very liquid and not thick), then such an oil can also be used and not changed. In the event that instead of forming a drop, the oil simply flows down over the surface of the dipstick (and even more so it is very dark), then such oil must be replaced as soon as possible.

Value for money

The ratio of low price and high-quality oil can also become an indirect sign that sellers are trying to sell counterfeit goods. No self-respecting oil manufacturer will significantly reduce the price of their products, so do not succumb to the persuasion of unscrupulous sellers.

Try to buy engine oils in trusted stores that have agreements with official representatives (dealers) of lubricant manufacturers.

Oil drop test

However, the most common method by which the quality of an oil can be determined is the drop test method. It was invented by SHELL in 1948 in the USA, and with it you can quickly check the condition of the oil with just one drop of it. And even a novice driver can do it. True, this test sample is most often used not for fresh, but for already used oil.

With the help of a drop test, you can not only determine the quality of engine oil, but also check the following parameters:

- the condition of rubber gaskets and seals in the internal combustion engine;

- engine oil properties;

- the state of the internal combustion engine as a whole (namely, whether it needs a major overhaul);

- determine when to change the oil in the car engine.

Algorithm for performing an oil test sample

How to make a drip test? To do this, you need to act according to the following algorithm:

- Warm up the internal combustion engine to operating temperature (it can be up to approximately +50 ... + 60 ° С, in order not to burn yourself when taking a sample).

- Prepare a blank white sheet of paper in advance (its size does not really matter, a standard A4 sheet folded in two or four layers will do).

- Open the crankcase filler cap, and use a dipstick to put one or two drops on a sheet of paper (at the same time you can check the engine oil level in the internal combustion engine).

- Wait 15…20 minutes so that the oil is well absorbed into the paper.

The quality of engine oil is judged by the shape and appearance of the resulting oil stain.

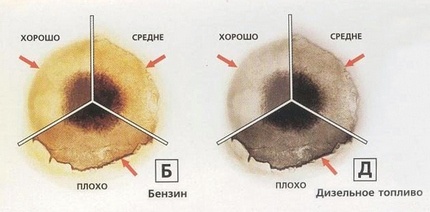

How to determine the quality of the oil by the type of stain

First of all, you need to pay attention to the color of the individual four zones formed within the boundaries of the spot.

- The central part of the spot is the most important! If the oil is of poor quality, then soot particles and mechanical impurities usually occur in it. For natural reasons, they cannot be absorbed into the paper. usually, the central part of the spot is darker than the rest.

- The second part is exactly the oil stain. That is, the oil that has been absorbed into the paper and does not have additional mechanical impurities. The darker the oil, the older it is. However, additional parameters are needed for the final solution. Diesel engines will have darker oil. also, if the diesel engine smokes heavily, then in the drop sample there is often no boundary between the first and second zones, that is, the color changes smoothly.

- The third zone, remote from the center, is represented by water. Its presence in the oil is undesirable, but not critical. If there is no water, the edges of the zone will be smooth, close to a circle. If there is water, the edges will be more zigzag. Water in oil can have two origins - condensation and coolant. The first case is not so terrible. If glycol-based antifreeze gets into the oil, then a yellow ring, the so-called crown, will appear on top of the zigzag border. If there are a lot of mechanical deposits in the oil, then soot, dirt and impurities can be not only in the first, but also in the second and even third circular zone.

- The fourth zone is represented by the presence of fuel in the oil. Therefore, in serviceable internal combustion engines, this zone should not be present or it will be minimal. If the fourth zone takes place, then it is necessary to revise the internal combustion engine. The larger the diameter of the fourth zone, the more fuel in the oil, which means that the car owner should be more worried.

Sometimes an additional test is performed to assess the presence of water in the oil. So, for this paper is burned. When the third zone burns, a characteristic crackling sound is heard, similar to a similar crackling when burning damp firewood. The presence of even a small amount of water in the oil can lead to the following unpleasant consequences:

- The protective properties of the oil deteriorate. This is due to the rapid wear of detergents and dispersants in contact with water, and this, in turn, leads to increased wear of the piston group parts and accelerates the contamination of the internal combustion engine.

- Contaminant particles increase in size, thereby clogging the oil passages. And this negatively affects the lubrication of the internal combustion engine.

- The hydrodynamics of bearing lubrication increases, and this negatively affects them.

- The freezing point (solidification) of the oil in the engine rises.

- The viscosity of the oil in the internal combustion engine changes, it becomes thinner, albeit slightly.

Using the drip method, you can also find out how good the dispersing properties of the oil are. This indicator is expressed in arbitrary units and is calculated by the following formula: Ds = 1 - (d2/d3)², where d2 is the diameter of the second oil spot zone, and d3 is the third one. It is better to measure in millimeters for convenience.

It is considered that the oil has satisfactory dispersing properties if the value of Ds is not lower than 0,3. Otherwise, the oil needs an urgent replacement with a better (fresh) lubricating fluid. Experts recommend carry out a drip test of engine oil every one and a half to two thousand kilometers a car.

The drop test result is tabulated

| Value | transcript | Recommendations for use |

|---|---|---|

| 1, 2, 3 | The oil does not contain dust, dirt and metal particles, or they are contained, but in small quantities | ICE operation is allowed |

| 4, 5, 6 | The oil contains a moderate amount of dust, dirt and metal particles. | It is allowed to operate internal combustion engines with periodic checks of oil quality |

| 7, 8, 9 | The content of insoluble mechanical impurities in the oil exceeds the norm | ICE operation is not recommended. |

Remember that color changes in one direction and the other do not always indicate changes in the characteristics of the oil. We have already mentioned fast blackening. However, if your car is equipped with LPG equipment, then on the contrary, the oil may not turn black for a long time and even have a more or less light shade even with a significant vehicle mileage. But that doesn't mean it can be used forever. The fact is that in combustible gases (methane, propane, butane) there are naturally fewer additional mechanical impurities that pollute the oil. Therefore, even if the oil in a car with LPG does not darken significantly, it still needs to be changed according to the schedule.

Advanced drop method

The classical method of performing a drop test has been described above. However, more and more motorists are now using the improved method developed by MOTORcheckUP AG based in Luxembourg. In general, it represents the same procedure, however, instead of the usual blank sheet of paper, the company offers a special paper "filter", in the center of which is a special filter paper, where you need to drop a small amount of oil. As in the classic test, the oil will spread into four zones, by which it will be possible to judge the state of the lubricating fluid.

In some modern ICEs (for example, the TFSI series from VAG), mechanical probes have been replaced with electronic ones. Accordingly, a car enthusiast is deprived of the opportunity to independently take an oil sample. In such cars there is both an electronic level and a special sensor for the quality and condition of the oil in the car.

The principle of operation of the oil quality sensor is based on monitoring the change in the dielectric constant of the oil, which changes depending on the oxidation and the amount of impurities in the oil. In this case, it remains to rely on “smart” electronics or seek help from a service center so that their employees check the oil in the engine crankcase of your car.

Some manufacturers of motor oils, for example, Liqui Moly (Molygen series) and Castrol (Edge, Professional series), add pigments that glow in ultraviolet rays to the composition of lubricating fluids. Therefore, in this case, originality can be checked with an appropriate flashlight or lamp. Such a pigment is preserved for several thousand kilometers.

Portable pocket oil analyzer

Modern technical capabilities make it possible to determine the quality of the oil not only “by eye” or using the drop test described above, but also with the help of additional hardware. namely, we are talking about portable (pocket) oil analyzers.

In general, the procedure for working with them is to place a small amount of lubricating fluid on the working sensor of the device, and the analyzer itself, using the software embedded in it, will determine how good or bad its composition is. Of course, he will not be able to make a full-fledged chemical analysis and give detailed information about certain characteristics, however, the information provided is quite enough to get a general picture of the condition of the engine oil for the driver.

In reality, there are a large number of such devices, and, accordingly, their capabilities and features of work may differ. However, most often, like the popular Lubrichek, they are an interferometer (devices operating on the physical principle of interference), with which the following (or some of the listed) indicators can be determined for oils:

- the amount of soot;

- oxidation states;

- degree of nitriding;

- degree of sulfation;

- phosphorus anti-seize additives;

- water content;

- glycol (antifreeze) content;

- diesel fuel content;

- gasoline content;

- total acid number;

- total base number;

- viscosity (viscosity index).

Characteristics of engine oils

The physical and chemical analysis of motor oil includes: viscosity index, ash content, alkaline numbers and other indicators. What does this mean? Let's consider the influence of basic technical characteristics on the quality and properties of internal combustion engine lubricants Read more

The size of the device, its technical characteristics, etc. can vary greatly. The most advanced models display test results on the screen in just a few seconds. They can transmit and receive data via the USB standard. Such devices can even be used in quite serious chemical laboratories.

However, the most simple and cheap samples simply show in points (for example, on a 10-point scale) the quality of the engine oil being tested. Therefore, it is easier for an ordinary motorist to use just such devices, especially considering the difference in their price.