How often should the alternator belt be changed?

In any car, except for the internal combustion engine itself, there is additional, so-called attachments. These are independent devices that ensure the correct functioning of the internal combustion engine or are used for other purposes not directly related to the internal combustion engine. These attachments include a water pump, a power steering pump, an air conditioning compressor and a generator, from which the battery is charged and power is supplied to all systems and devices while the vehicle is moving.

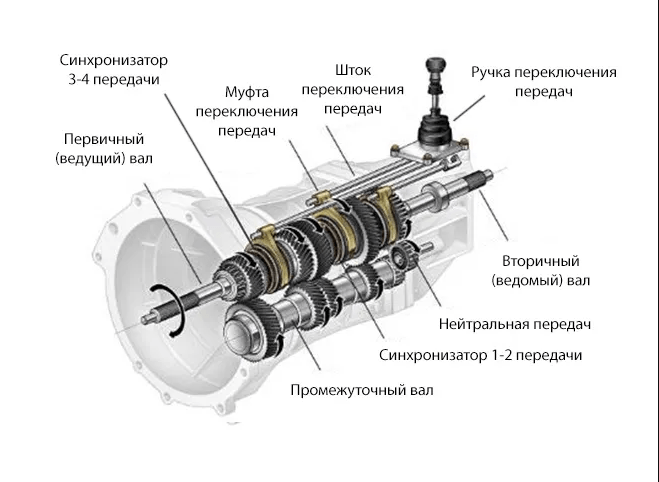

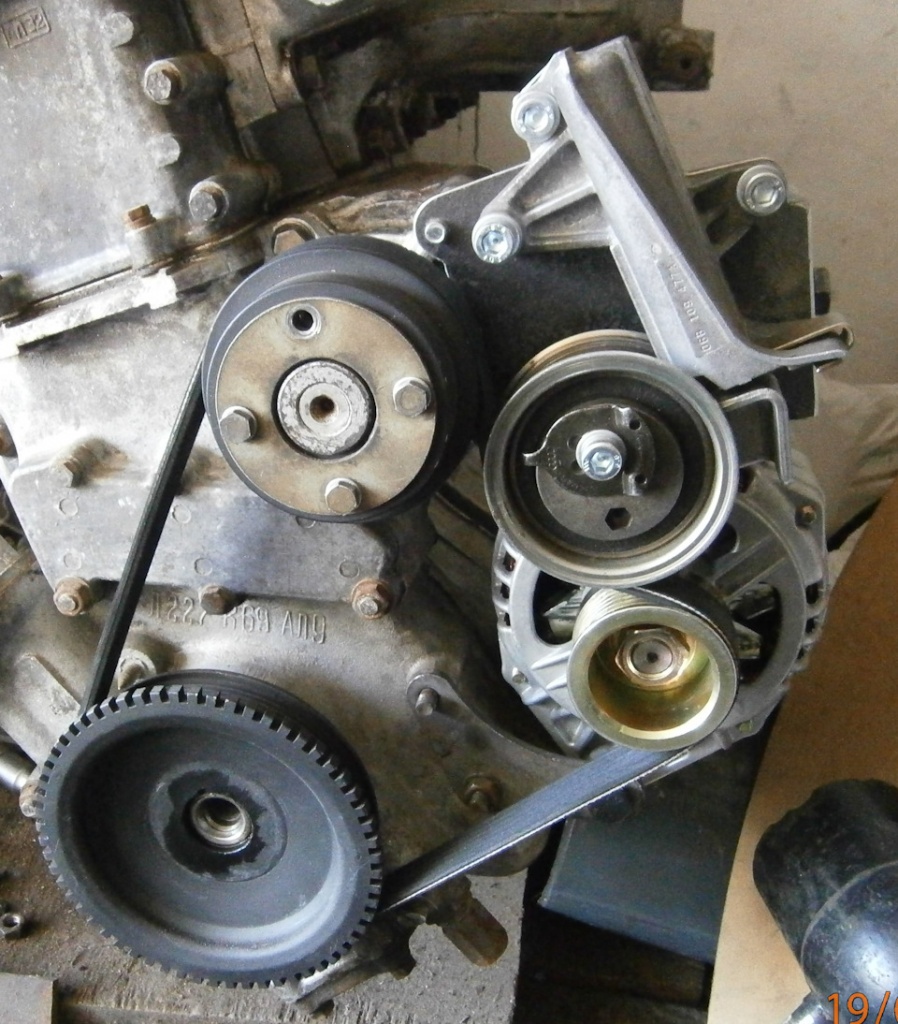

The generator and other attachments are driven by a drive belt from the crankshaft. It is put on pulleys, which are fixed at the end of the crankshaft and the generator shaft, and tensioned using a tensioner.

Most often, car owners have to deal with the stretching of the drive belt. In most cases, this happens over time as a result of normal wear and tear. Stretching can also contribute to the impact on the rubber of fuels and lubricants. In addition, premature stretching may occur due to the initial poor quality of the product. A sagging strap can be tightened, and perhaps it will last a long time.

General wear usually appears after the drive has been in operation for a long time. Rubber wear due to friction on the pulleys gradually leads to a decrease in the profile and slipping of the belt. This is usually accompanied by a characteristic whistle coming from under the hood. Because the drive belt slips, the generator cannot produce enough power to provide adequate electrical power, especially at full load. Charging is also slower.

Rubber delamination is possible in case of violation of the parallelism of the axes and the generator, or due to deformation of the pulleys, when intense uneven abrasion of the edge occurs. It happens that the cause of this phenomenon is a banal defect of the product.

A break is an extreme manifestation of problems with the generator drive. Either the owner of the car did not monitor its condition, or a low-quality product came across. In addition, a break can occur if one of the devices to which this drive transmits rotation is jammed. So that such a situation does not take you by surprise far from civilization, you should always have a spare drive belt with you, even if it was in use.

1. Workmanship. The drive installed at the factory usually works out the prescribed period without problems. Universal products that are sold in stores can last a long time if made from quality materials in compliance with proper technological standards. But it's not worth chasing cheapness. A cheap belt has a low price for a reason, such products are torn at the most unexpected moment.

2. Operating conditions. If dirt and aggressive substances get on the generator drive, the strap will become unusable ahead of schedule. Severe frost and sudden changes in temperature also do not benefit rubber.

3. Driving style. Aggressive driving style creates the maximum load on almost all units and systems of the car. Naturally, the alternator belt is also under increased load, which means that it will have to be changed more often.

4. Faulty tensioner or incorrectly adjusted tension. If the drive is overtightened, the risk of breakage increases. A slack belt experiences increased friction against the pulleys as it slips.

5. Violation of the parallelism of the axes of the crankshaft, generator or other devices that are driven by this drive, as well as a defect in the pulleys of these devices.

There is usually no strict regulation of the timing of changing the drive belts of mounted units. The working life of the alternator belt is usually approximately 50 ... 60 thousand kilometers. Automakers recommend checking its condition every 10 thousand kilometers or every six months, and changing it as needed.

The need to change the drive may be indicated by a decrease in the performance of the generator (if there is an appropriate sensor) and specific sounds under the hood, especially during the start of the internal combustion engine or when the speed increases. However, sounds can occur not only due to a worn belt.

If the drive emits a high frequency whine, the cause may be incorrect installation or deformation of one of the pulleys.

Drive grinding can also be caused by an incorrectly installed or damaged pulley. In addition, in this case, it is necessary to diagnose the bearings and the tensioner.

For low frequency noise, try cleaning the pulleys first.

If a hum is heard, the bearing is most likely the culprit.

Drive vibrations can occur due to a damaged pulley or a faulty tensioner.

Before changing the alternator belt, diagnose all other drive elements and repair the damage, if any. If this is not done, the new strap may fail much earlier.

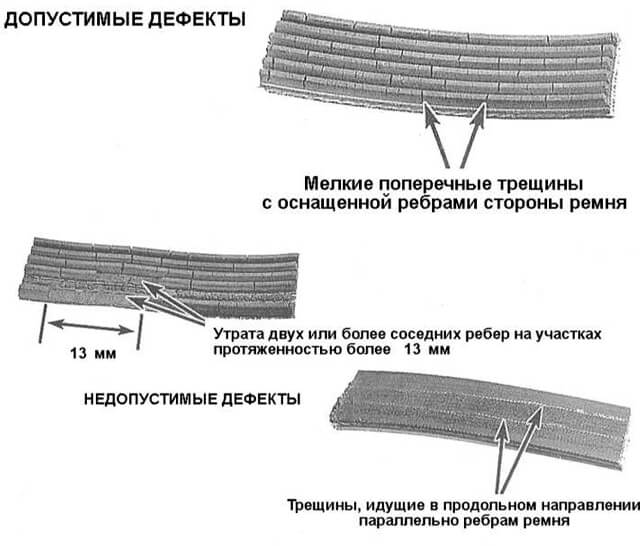

The condition of the belt itself is determined by visual inspection. Scrolling the crankshaft by hand, carefully inspect the strap along its entire length. It should not have deep cracks or delaminations. Serious defects even in a small area are the basis for a change.

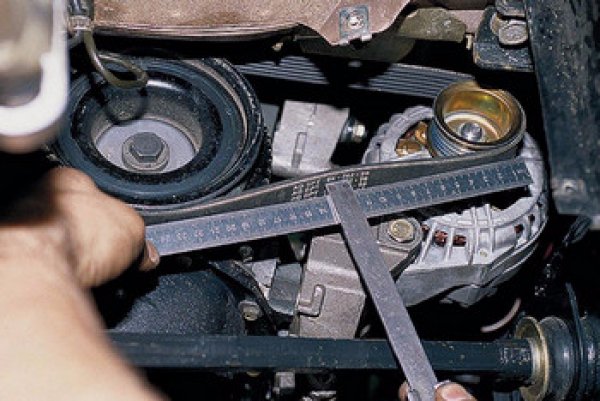

If the belt is in satisfactory condition, diagnose its tension. When exposed to a load of 10 kgf, it should bend by about 6 mm. If the length between the axes of the pulleys is more than 300 mm, a deflection of about 10 mm is allowed.

Adjust tension if necessary. Just do not pull too hard, this can create an excessive load on the alternator bearing, and the belt itself will wear out faster. If the tightening does not work, then the belt is too stretched and needs to be replaced.

You can purchase generator drives and other attachments for Chinese cars in the online store.

As a rule, the change process is not complicated and is quite accessible to most drivers.

Before starting work, you need to turn off the internal combustion engine, turn off the ignition and remove the wire from the negative terminal of the battery.

If more than two units are powered by one drive, draw a diagram of its location before disassembly. This will prevent confusion when installing a new belt.

The change algorithm may be different for different internal combustion engines and different attachments.

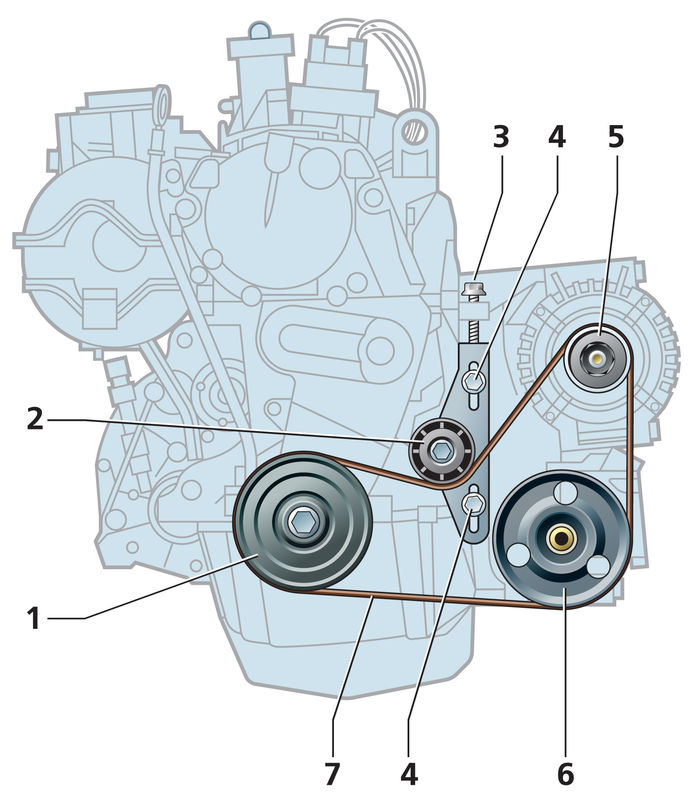

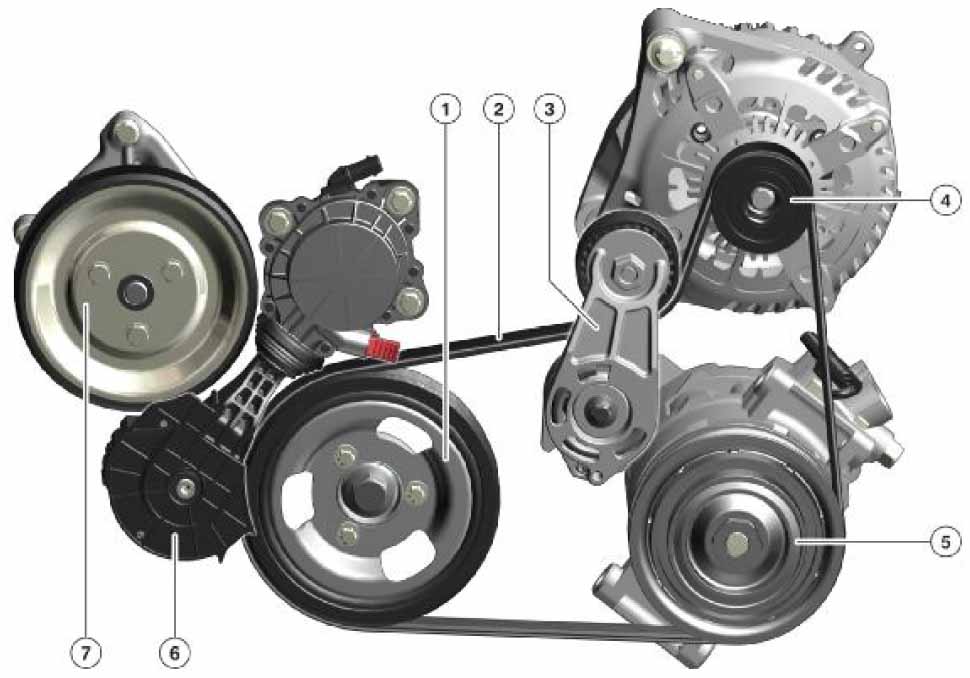

If the drive uses a mechanical tensioner with an adjusting bolt (3), then use it to loosen the belt tension. In this case, it is not necessary to completely unscrew the bolt. In many cases, you will additionally need to loosen the alternator housing (5) and move it so that the strap can be removed from the pulleys without much effort.

In some models, the tension is carried out directly by the generator without an additional tensioner.

If the drive is equipped with an automatic tensioner (3), first loosen the pressure roller and move (turn) it so that the belt (2) can be removed. then the roller must be fixed in the depressed position. After installing the belt on the pulleys of the crankshaft (1), generator (4) and other devices (5), the roller carefully returns to its working position. Tension adjustment is automatic and does not require human intervention.

After completing the work, diagnose if everything is in order. Connect the previously removed wire to the battery, start the internal combustion engine and give the generator maximum load by turning on the heater or air conditioner, headlights, audio system. then give the load on the internal combustion engine. If the drive whistles, tighten it up.