How to understand compression and power systems in small engines

Content

Although engines have evolved over the years, all gasoline engines operate on the same principles. The four strokes that occur in an engine allow it to create power and torque, and that power is what drives your car.

Understanding the basic principles of how a four-stroke engine works will help you diagnose engine problems and also make you a well-informed buyer.

Part 1 of 5: Understanding the Four-Stroke Engine

From the first gasoline engines to the modern engines built today, the principles of the four-stroke engine have remained the same. Much of the engine's external operation has changed over the years with the addition of fuel injection, computer control, turbochargers and superchargers. Many of these components have been modified and changed over the years to make engines more efficient and powerful. These changes have allowed manufacturers to keep pace with the desires of consumers, while achieving environmentally friendly results.

A gasoline engine has four strokes:

- Intake stroke

- Compression cycle

- power stroke

- Release cycle

Depending on the type of engine, these knocks can occur several times per second while the engine is running.

Part 2 of 5: Intake Stroke

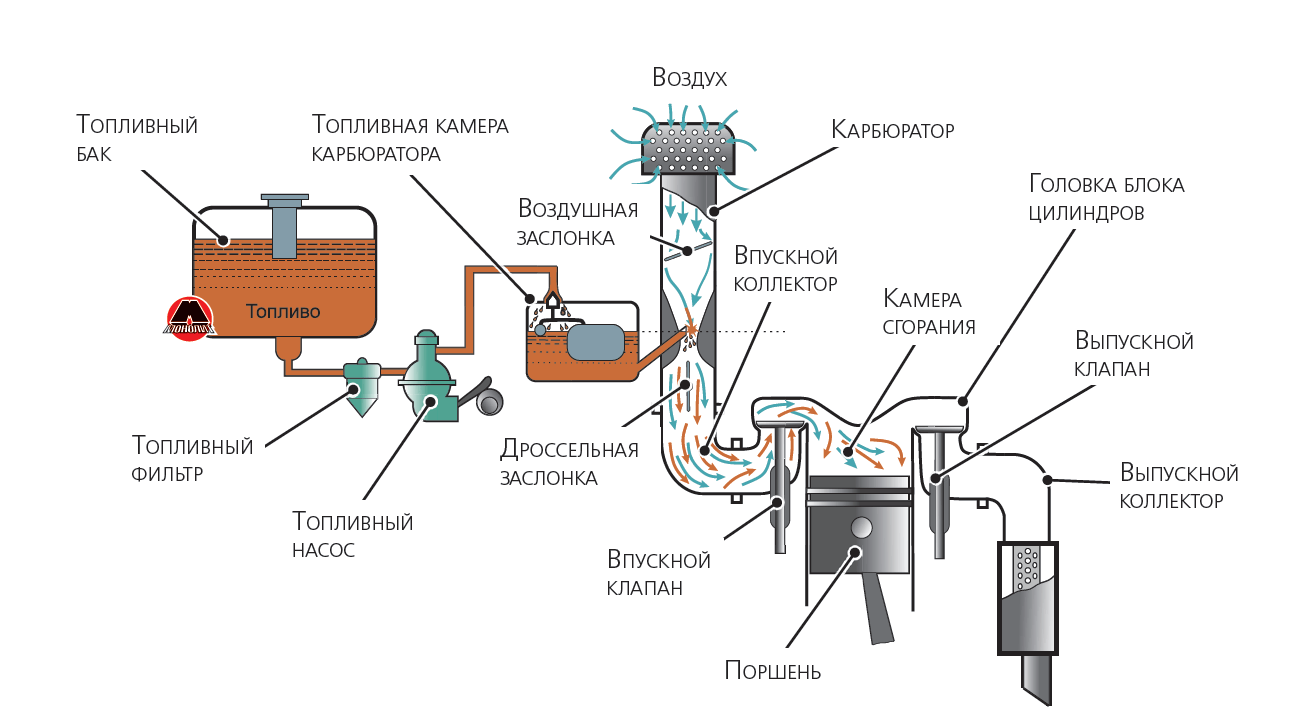

The first stroke that occurs in the engine is called the intake stroke. This happens when the piston moves down in the cylinder. When this happens, the intake valve opens, allowing the mixture of air and fuel to be drawn into the cylinder. Air is drawn into the engine from the air filter, through the throttle body, down through the intake manifold, until it reaches the cylinder.

Depending on the engine, fuel is added to this air mixture at some point. In a carbureted engine, fuel is added as air passes through the carburetor. In a fuel injected engine, fuel is added at the location of the injector, which can be anywhere between the throttle body and cylinder.

As the piston pulls down on the crankshaft, it creates suction which allows the mixture of air and fuel to be drawn in. The amount of air and fuel sucked into the engine depends on the design of the engine.

- Attention: Turbocharged and supercharged engines work in the same way, but they tend to produce more power as the mixture of air and fuel is forced into the engine.

Part 3 of 5: Compression stroke

The second stroke of the engine is the compression stroke. Once the air/fuel mixture is inside the cylinder, it must be compressed so that the engine can produce more power.

- Attention: During the compression stroke, the valves in the engine are closed to prevent the air/fuel mixture from escaping.

After the crankshaft has lowered the piston to the bottom of the cylinder during the intake stroke, it now begins to move back up. The piston continues to move towards the top of the cylinder where it reaches what is known as top dead center (TDC), which is the highest point it can reach in the engine. When top dead center is reached, the air-fuel mixture is fully compressed.

This fully compressed mixture resides in an area known as the combustion chamber. This is where the air/fuel mixture is ignited to create the next stroke in the cycle.

The compression stroke is one of the most important factors in engine building when you are trying to generate more power and torque. When calculating engine compression, use the difference between the amount of space in the cylinder when the piston is at the bottom and the amount of space in the combustion chamber when the piston reaches top dead center. The greater the compression ratio of this mixture, the greater the power generated by the engine.

Part 4 of 5: Power move

The third stroke of the engine is the working stroke. This is the stroke that creates power in the engine.

After the piston reaches top dead center on the compression stroke, the air-fuel mixture is forced into the combustion chamber. The air-fuel mixture is then ignited by a spark plug. The spark from the spark plug ignites the fuel, causing a violent, controlled explosion in the combustion chamber. When this explosion occurs, the force generated presses on the piston and moves the crankshaft, allowing the engine's cylinders to continue working through all four strokes.

Keep in mind that when this explosion or power strike occurs, it must occur at a certain time. The air-fuel mixture must ignite at a certain point depending on the design of the engine. In some engines, the mixture must ignite near top dead center (TDC), while in others the mixture must ignite a few degrees after this point.

- Attention: If the spark does not occur at the right time, engine noise or serious damage may occur, resulting in engine failure.

Part 5 of 5: Release stroke

The release stroke is the fourth and final stroke. After the completion of the working stroke, the cylinder is filled with exhaust gases remaining after the ignition of the air-fuel mixture. These gases must be purged from the engine before restarting the entire cycle.

During this stroke, the crankshaft pushes the piston back into the cylinder with the exhaust valve open. As the piston moves up, it pushes the gases out through the exhaust valve, which leads into the exhaust system. This will remove most of the exhaust gases from the engine and allow the engine to start again on the intake stroke.

It is important to understand how each of these strokes work on a four-stroke engine. Knowing these basic steps can help you understand how an engine generates power, as well as how it can be modified to make it more powerful.

It is also important to know these steps when trying to identify an internal engine problem. Keep in mind that each of these strokes performs a specific task that must be synchronized with the engine. If any part of the engine fails, the engine will not run correctly, if at all.