How to change a brake caliper

Content

Car brake calipers last longer with regular brake bleeding. Replacing the brake calipers is necessary to keep the brake pads working properly.

The brake caliper contains a brake piston which is then used to apply pressure to the pads and rotor. The piston has a square seal inside which prevents brake fluid leakage and allows the piston to move back and forth. Over time, seals can fail and fluid will leak out. This is very dangerous as it will slow down the brakes and you will not be able to effectively stop the car.

The main thing that these seals do not fail is regular maintenance of the brakes, namely bleeding the brakes. Bleeding your brakes regularly will keep the fluid fresh and make sure there is no fluid or dirt in the brake lines. Dirt and rust caused by water ingress into the piping can corrode the seal until it fails completely.

It is possible to rebuild a caliper with a new seal and piston, but it is much easier to buy a new caliper. Rebuilding a caliper requires special tools to remove the piston, whereas if you have the tools to replace brake pads, you already have almost all the tools you need to do the job.

Part 1 of 4: Remove the old caliper

Necessary materials

- Brake cleaner

- Switch

- Elastic cord

- Gloves

- socket

- Jack stands

- rags

- ratchet

- Silicone based lubricant

- Socket set

- thread blocker

- Wrench

Wire brush

AttentionA: You will need several sizes of sockets and these will vary depending on the type of vehicle. The caliper slide pin bolts and mounting bolts are about 14mm or ⅝ inch. The most common lug nut sizes are 19mm or 20mm metric. ¾” and 13/16” are commonly used for older domestic cars.

Step 1: Raise the vehicle off the ground. On a hard, level surface, use a jack and raise the vehicle. Put the car on jack stands so it won't fall while we're under it. Block any wheels that are still on the ground so they cannot roll.

- Functions: If you are using a breaker, be sure to loosen the lug nuts before lifting the vehicle. Otherwise, you will just spin the wheel, trying to loosen them in the air.

Step 2: remove the wheel. This will expose the caliper and rotor so we can work.

- Functions: Watch your nuts! Put them in a tray so they can't roll away from you. If your car has hubcaps, you can turn them over and use them as a tray.

Step 3: Remove the Top Slider Pin Bolt. This will allow us to open the caliper to remove the brake pads. If we don't remove them now, they will likely fall out when the entire caliper assembly is removed.

Step 4: Rotate the caliper body. Like a clam shell, the body can pivot up and open, allowing you to remove the pads later.

- Functions: Use a flathead screwdriver or small pry bar to open the caliper if there is resistance.

Step 5: Close the caliper. With the pads removed, close the caliper and hand-tighten the slider bolt to hold the parts together.

Step 6: Loosen the banjo bolt. While the caliper is still attached to the hub, we will loosen the bolt to make it easier to remove later. Tighten it slightly to prevent liquid from escaping.

If you remove the caliper and try to loosen the bolt later, you will probably need a vise to hold the caliper in place.

- Attention: As soon as you loosen the bolt, the fluid will start to flow out. Get your cleaning rags ready.

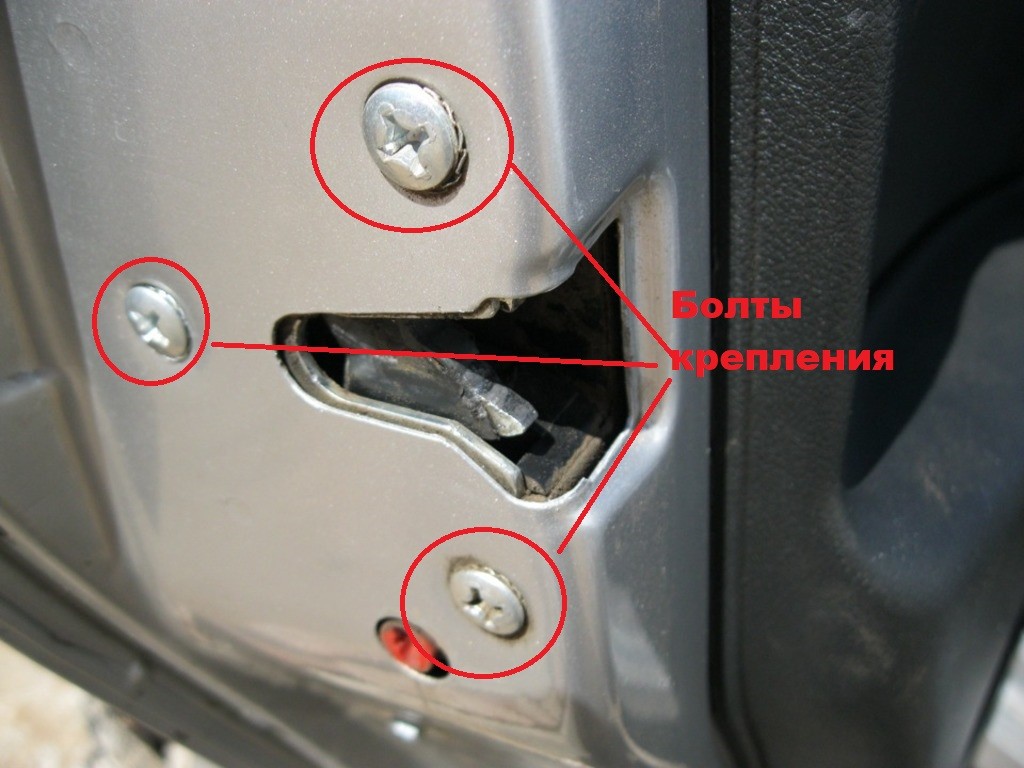

Step 7: Remove one of the caliper mounting bracket bolts.. They will be closer to the center of the wheel on the back side of the wheel hub. Unscrew one of them and set aside.

- Functions: The manufacturer usually uses a threadlocker on these bolts to prevent them from coming loose. Use a broken bar to help undo them.

Step 8: Get a firm grip on the caliper. Before removing the second bolt, make sure you have a hand supporting the weight of the caliper as it will fall. They tend to be heavy so be prepared for the weight. If it falls, the weight of the caliper pulling the lines could cause significant damage.

- Functions: Get as close as possible while supporting the caliper. The farther you are, the harder it will be to support the weight of the caliper.

Step 9: Remove the second caliper mounting bracket bolt.. Keeping one hand under the caliper, supporting it, with the other hand unscrew the bolt and remove the caliper.

Step 10: Tie the caliper down so it doesn't dangle. As mentioned earlier, we don't want the weight of the caliper to pull on the brake lines. Find a strong part of the pendant and tie the caliper to it with an elastic cord. Wrap around a few times to make sure it doesn't fall off.

- Functions: If you do not have an elastic cable or rope, you can install a caliper on a strong box. Make sure there is some slack in the line so that there is not too much tension on them.

Step 11: Use Clamp Nuts to Hold the Rotor in Place. Take two nuts and screw them back onto the studs. This will hold the rotor in place when we install the new caliper and make the job a little easier.

Part 2 of 4. Setting up a new caliper

Step 1: Clean mounting bolts and apply new threadlocker.. Before putting the bolts back in, we need to clean them up and apply new threadlocker. Spray some brake cleaner and use a wire brush to thoroughly clean the threads. Make sure they are completely dry before applying new threadlocker.

- Attention: Only use thread lock if it has been used before.

Step 2: Install the new caliper and mount. Start with the top bolt and tighten it a few turns. This will help line up the bottom bolt hole.

Step 3: Tighten the mounting bolts to the correct torque.. Specifications vary from car to car, but you can find them online or in a car repair manual.

- Attention: Torque specifications exist for a reason. Tightening the bolts too much stretches the metal and makes the connection weaker than before. Too loose fastening and vibrations can cause the bolt to start to unscrew.

Part 3 of 4: Transferring the brake line to a new caliper

Step 1: Remove the banjo fitting from the old caliper.. Unscrew the bolt and remove the banjo. The liquid will pour out again, so get some rags ready.

- Step 2: Remove the old washers from the fitting.. The new caliper will come with fresh washers that we will use. Also clean the banjo bolt with brake cleaner.

One will be between the fitting and the caliper.

The other will be on the bolt. It can be thin and it's hard to tell if there's a puck, but it's there. When you tighten the banjo fitting, it compresses the washer lightly, creating a tight seal so fluid doesn't leak out under pressure.

- Attention: If you don't remove the old washers, the new caliper won't seal properly and you'll have to take it all apart again to fix it.

Step 3: Install New Washers. Install new washers in the same places as before. One on the bolt and one between the fitting and the caliper.

Step 4: Tighten the banjo bolt. Use a torque wrench to get the correct torque value. The torque specification can be found online or in a car repair manual.

Part 4 of 4: Putting it all back together

Step 1: Reinstall the brake pads. Remove the slider top bolt and open the caliper to put the brake pads back in.

- Attention: A new caliper may use different sizes of bolts, so check the dimensions before you start to unscrew them with a ratchet.

Step 2: Install the new anti-vibration clamps into the new caliper.. The new caliper should have new clips. If not, you can reuse them from an old caliper. These clamps prevent the brake pads from rattling inside the caliper.

- Functions: Refer to the old caliper if you are not sure where they should go.

Step 3: Lubricate the back of the brakes. Without any kind of lubrication, disc brakes tend to squeak when metal rubs against each other. Apply a thin coat to the back of the brakes and to the inside of the caliper where they rub against each other.

You can also put some on the anti-vibration clamps where the pads slide back and forth.

- AttentionA: You don't need very much. It's much safer to apply too little and make the brakes make some noise than to apply too much and leak the brake pads.

Step 4: Close the caliper. Close the caliper and tighten the upper slider bolt to specification. A new caliper may have a different torque than the original, so check the instructions for the correct value.

Step 5: Open the outlet valve. This will help start the bleed process by allowing air to start escaping from the valve. Gravity will help push the fluid down, and when the fluid starts to come out of the valve, push it down firmly. Not too tight as we still need to open the valve to pump out the remaining air.

Loosen the master cylinder cover to speed up the process. Be prepared to close the valve as this really helps the fluid move through the lines.

- Functions: Place a rag right under the exhaust valve to soak up the brake fluid. It's much more important to make sure all the fluid is flushed out on your new calipers than on your old ones.

Step 6: Bleeding the Brakes. There will still be some air in the brake lines and we need to bleed it out so the pedal isn't spongy. You only need to bleed the lines of the calipers you have replaced.

A warning: Make sure the master cylinder never runs out of fluid or you'll have to start over. Check fluid level after each caliper bleeding.

Attention: All cars have a certain procedure for bleeding calipers. Make sure you bleed them in the correct order, otherwise you won't be able to completely bleed the lines. In most cars, you start with the caliper furthest away from the master cylinder and work your way up. So if the master cylinder is on the driver's side, the order would be right rear caliper, left rear caliper, right front caliper, and left front caliper would come last.

Functions: You can bleed the brakes yourself, but it's much easier with a friend. Have them bleed the brakes while you open and close the exhaust valves.

Step 7: Reinstall the wheel. After bleeding the brakes, make sure that the calipers and lines are completely free of brake fluid, and reinstall the wheel.

Make sure to tighten with the correct torque.

Step 8: Time for a Test Drive: Make sure there is enough room ahead in case the brakes do not work properly. Start at a very low speed to make sure the brakes can stop the car a little.

After a couple of starts and stops, check for leaks. Mostly on the banjo rebar we passed on. If you can't see it through the wheel, you may need to take it off to check. It's worth taking the time to make sure everything works as intended before driving out on the actual streets.

With brand new calipers and piping, your brakes should feel almost like new. As mentioned earlier, bleeding your brakes regularly can actually extend the life of your calipers as it keeps the fluid fresh, which keeps your seals intact. If you have any problems when replacing calipers, our certified AvtoTachki specialists will be able to help you with their replacement.