How to test the throttle position sensor with a multimeter

Content

When an electrical component in your fuel injection system fails, you certainly expect your engine to perform poorly.

In the long run, if these problems are not addressed, your engine will suffer, gradually fail, and may stop working altogether.

The throttle position sensor is one such component.

However, the symptoms of a faulty TPS are usually the same as those of other faulty electrical components, and not many people know how to diagnose problems with it.

This guide explains everything you need to know about checking the throttle position sensor, including what it does to the engine and how to do a quick test with a multimeter.

Let's get started.

What is a throttle position sensor?

The Throttle Position Sensor (TPS) is an electrical component in your vehicle's fuel management system that controls air flow to the engine.

It is mounted on the throttle body and directly monitors the throttle position and sends signals to the fuel injection system to ensure that the correct mixture of air and fuel is supplied to the engine.

If the TPS is faulty, you will experience certain symptoms such as ignition timing problems, increased fuel consumption, and uneven engine idling, among many others.

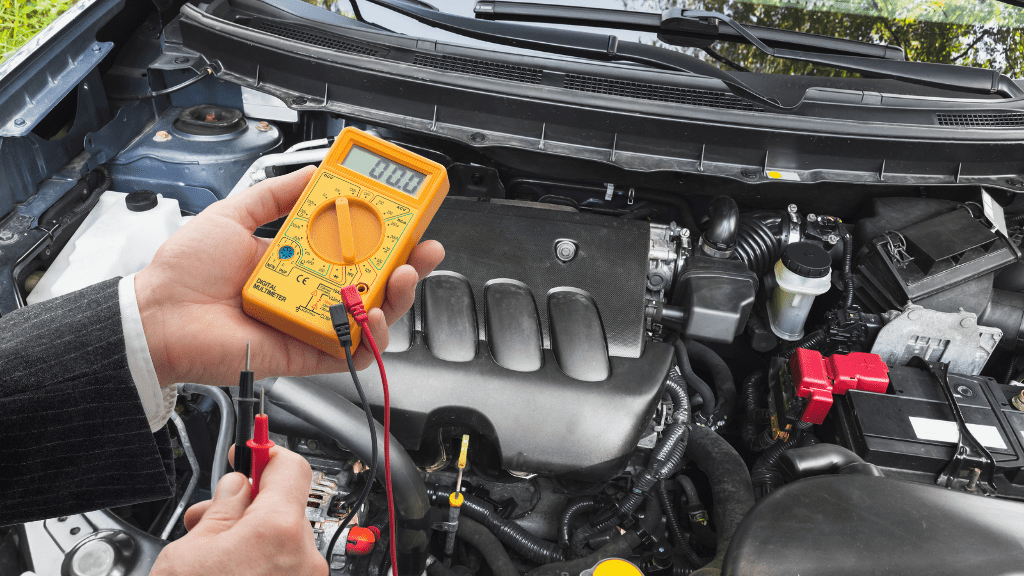

A multimeter is a great tool you need to check your car's electrical components and will come in handy if you run into any of them.

Now let's see how to diagnose the throttle position sensor?

How to test the throttle position sensor with a multimeter

Set the multimeter to the 10 VDC voltage range, place the black negative lead on the TPS ground terminal and the red positive lead on the TPS reference voltage terminal. If the meter does not show 5 volts, the TPS is faulty.

This is just one test in a series of tests you run on the throttle position sensor, and we're going to dive into the details now.

- Clean the throttle

Before diving into the throttle position sensor with a multimeter, there are a few preliminary steps you should take.

One of these is cleaning the throttle body, as debris on it can prevent it from opening or closing properly.

Disconnect the air cleaner assembly from the throttle position sensor and check the throttle body and walls for carbon deposits.

Dampen a rag with carburetor cleaner and wipe off any debris where you see it.

After doing this, make sure the throttle valve opens and closes fully and properly.

It's time to move on to the throttle position sensor.

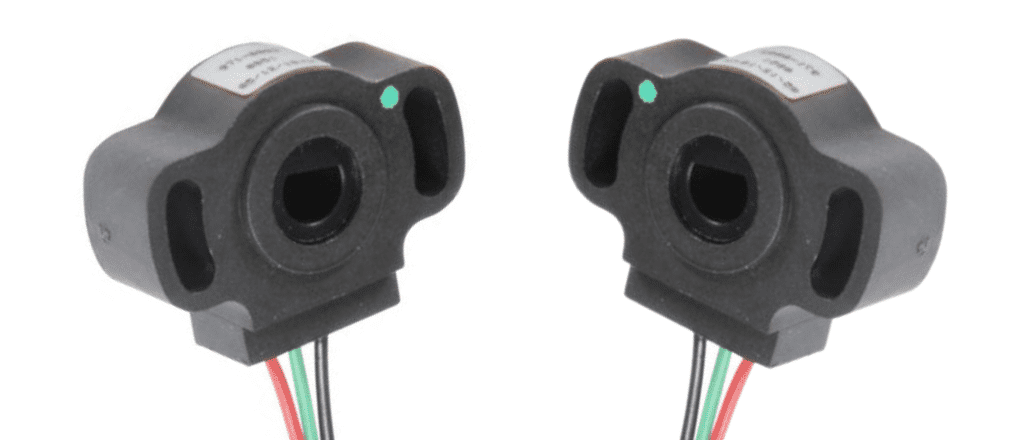

This is a small plastic device located on the side of the throttle body that has three different wires connected to it.

These wires or connector tabs are important for our tests.

If you're having trouble finding wires, check out our wire tracing guide.

Check the TPS wires and terminals for damage and buildup of dirt. Take care of any impurities and move on to the next step.

- Locate throttle position sensor ground

Throttle position ground detection determines if there is a problem and also helps with subsequent checks.

Set the multimeter to the 20 VDC voltage range, turn on the ignition without starting the engine, and then place the red positive test lead on the positive post of the car battery (marked "+").

Now place a black negative test lead on each of the TPS wire leads or terminals.

You do this until one shows you a reading of 12 volts. This is your ground terminal and your TPS has passed this test.

If none of the tabs show a 12-volt reading, then your TPS is not properly grounded and may need to be repaired or completely replaced.

If it is grounded, check the grounding tab and proceed to the next step.

- Locate the reference voltage terminal

With your vehicle's ignition still in the on position and the multimeter set to the 10VDC voltage range, place the black wire on the TPS ground terminal and place the red wire on each of the other two terminals.

The terminal that gives you about 5 volts is the reference voltage terminal.

If you don't get any 5 volt reading, it means there is a problem in your TPS circuit and you can check if the wiring is loose or corroded.

On the other hand, if the multimeter reads appropriately, then the appropriate reference voltage is being applied to the TPS signal terminal.

The signaling terminal is the third terminal that has not been tested.

Connect the wires back to the throttle position sensors and proceed to the next step.

- Check TPS signal voltage

The signal voltage test is the final test that determines if your throttle position sensor is working properly.

This helps diagnose if the TPS is accurately reading the throttle when it is fully open, half open, or closed.

Set the multimeter to the 10 VDC voltage range, place the black test lead on the TPS ground terminal and the red test lead on the signal voltage terminal.

It may be difficult to place the multimeter leads on the terminals since the TPS is already reconnected to the throttle.

In this case, you use pins to reverse-probe the wires (pierce each TPS wire with the pin) and attach the multimeter leads to these pins (preferably with alligator clips).

At wide throttle, the multimeter should read between 0.2 and 1.5 volts if the throttle position sensor is in good condition.

The displayed value depends on the model of your TPS.

If the multimeter reads zero (0), you can still proceed to the next steps.

Gradually open the throttle and watch the multimeter reading change.

Your multimeter is expected to display an ever-increasing value as you open the throttle.

When the plate is fully open, the multimeter should also display 5 volts (or 3.5 volts on some TPS models).

The TPS is in poor condition and needs to be replaced in the following cases:

- If the value skips massively when you open the tablet.

- If the value gets stuck on a number for a long period.

- If the value does not reach 5 volts when the throttle is fully open

- If the value is inappropriately skipped or changed by lightly tapping the sensor with a screwdriver

All these are ideas about the TPS, which needs to be replaced.

However, if your throttle position sensor is an adjustable model, like the ones used in older cars, then there is more to do before deciding to replace the sensor.

Directions for Variable Throttle Position Sensor

Adjustable throttle position sensors are the types that you can loosen and adjust by turning them left or right.

If your adjustable TPS is showing any of the symptoms mentioned above, you may want to readjust it before deciding to replace it.

The first step in this is to loosen the mounting bolts that secure it to the throttle body.

Once this is done you will feel the terminals again as the TPS is still connected to the throttle.

Connect the multimeter's negative lead to the TPS ground terminal and the positive lead to the signal terminal.

With the ignition on and throttle closed, turn the TPS left or right until you get the correct reading for your TPS model.

When you get the correct readings, simply hold the TPS in this position and tighten the mounting bolts on it.

If the TPS is still not reading properly, it is bad and you need to replace it.

Here is a video on how you can adjust the throttle position sensor.

This process depends on the adjustable TPS model you are using, and some may additionally require a dipstick or gauge to make adjustments.

OBD Scanner Codes for Throttle Position Sensor

Getting OBD scanner codes from your engine is one of the easiest ways to find throttle position sensor problems.

Here are three Diagnostic Trouble Codes (DTCs) to look out for.

- PO121: Indicates when the TPS signal is not consistent with the Manifold Absolute Pressure (MAP) sensor and may be caused by a malfunctioning TPS sensor.

- PO122: This is a low TPS voltage and can be caused by your TPS sensor terminal being open or shorted to ground.

- PO123: This is a high voltage and can be caused by a bad sensor ground or by shorting the sensor terminal to the reference voltage terminal.

Conclusion

That's all you need to know about checking the throttle position sensor.

As you can see from the steps, the model or type of TPS you use determines what to check and how these processes are performed.

While the tests are simple, see a professional mechanic if you run into problems.

F.A.Q.

How many volts should be in TPS?

The throttle position sensor is expected to read 5V when the throttle is closed and read 0.2 to 1.5V when the throttle is open.

What does a bad throttle position sensor do?

Some symptoms of bad TPS include limited vehicle speed, bad computer signals, ignition timing problems, shifting problems, rough idle, and increased fuel consumption, among others.

What are the 3 wires in the throttle position sensor?

The three wires in the throttle position sensor are the ground wire, the voltage reference wire, and the sensor wire. The sensor wire is the main component that sends the appropriate signal to the fuel injection system.