How to check evenness with an engineering ruler?

Content

Other equipment you will need: | ||

Thickness gaugeFeelers are thin strips of metal used to measure very small gaps between two objects. | ||

| LightA glare-free fluorescent light is used to check for gaps between the straight edge work surface and the workpiece. | |

| Spiritual LevelPlaced on top of an I-section or rectangular ruler, a spirit level can help check if the surface of the workpiece is flat and even. | |

Checking the cylinder block or cylinder head for flatness | ||

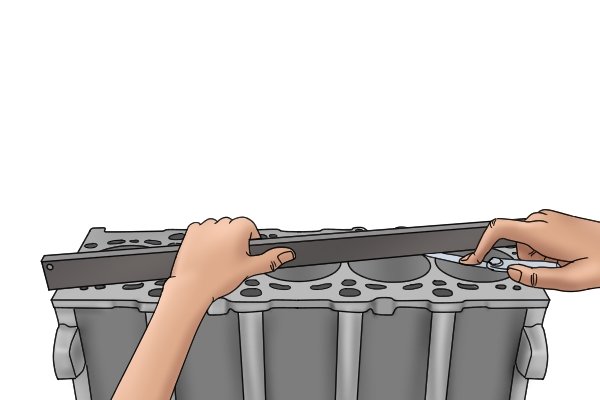

| An engineering ruler can be used to check the flatness of a cylinder block or cylinder head by placing them across their surface. | |

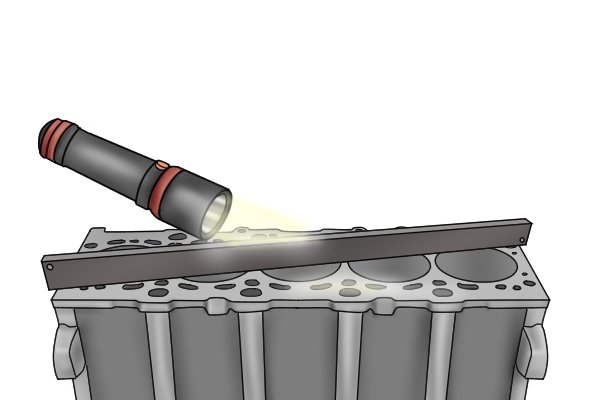

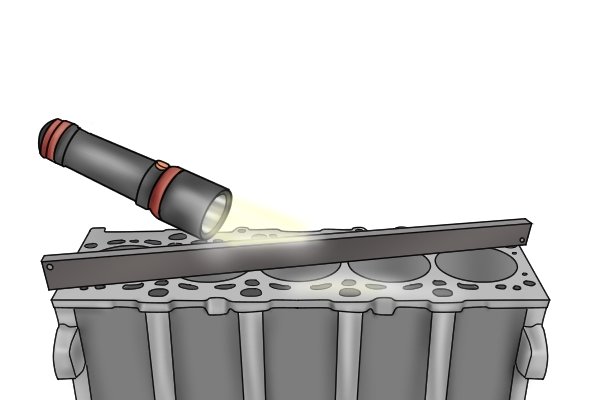

| By aiming the light behind the ruler, any gaps between the surface of the cylinder head and the ruler can be seen if their size exceeds 0.002 mm. Light is easier to see the thinner the ruler is, so sharp-edged rulers are the most accurate for this task, though you'll need to hold them as they won't stand up on their own. | |

| Any gaps should then be measured with a feeler gauge. | |

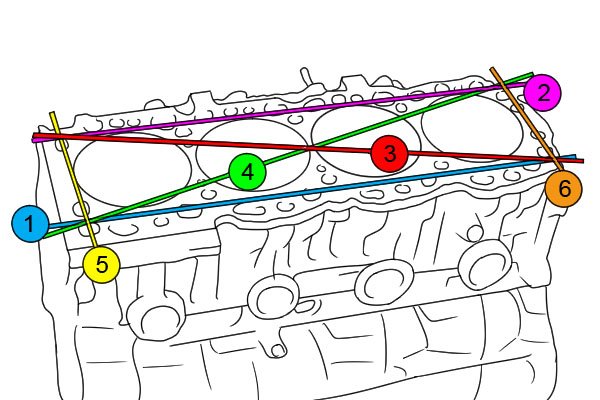

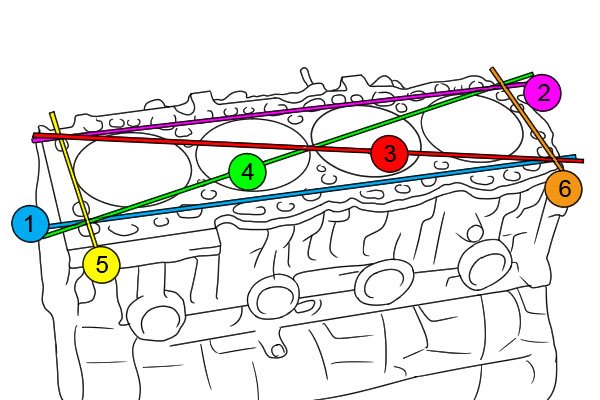

| This process must be repeated on six sections of the cylinder head. If the gaps in any area are outside the allowable limits for a given engine, then grinding of the cylinder head will be required. This process must then be repeated on the cylinder block to achieve a fit within the tolerances of the cylinder head and block combined. | |

| ||

Posted

in