How are engineering rulers made?

Content

Steel, cast iron and aluminum rulers | |

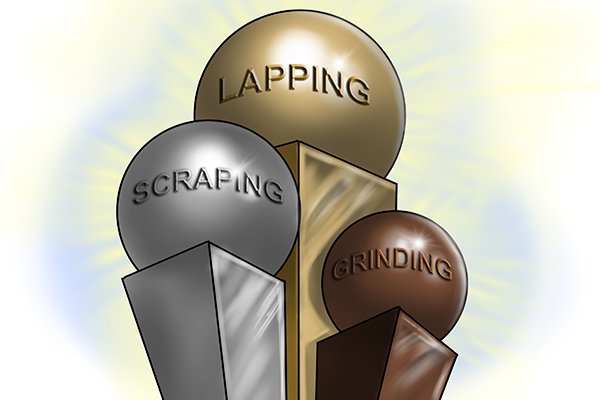

| The main processes that steel straight edges can go through to make them more suitable for their job are: heat treatment, tempering, scraping, grinding and lapping. Cast iron straight edges are often cast to the desired overall shape, and then their working surfaces are finished by scraping, grinding or lapping. | |

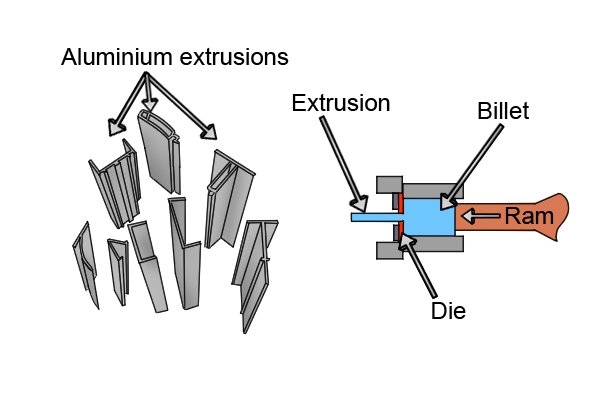

| Aluminum is often extruded as it can be a very fast and economical way to make items. However, an extruded aluminum ruler will require machining similar to a cast iron ruler in order to achieve the precision needed for the countertop. |

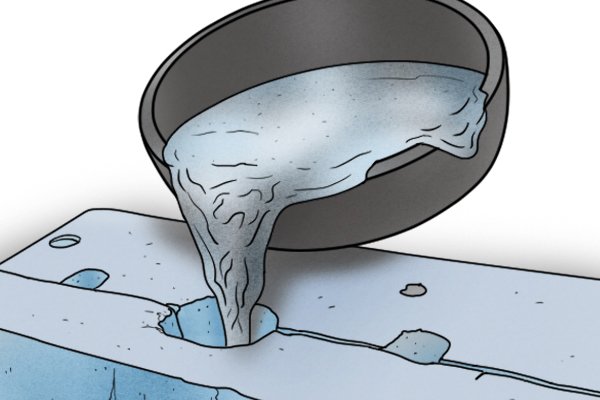

| CastingCasting is a manufacturing process that involves pouring molten metal into a mould, where it cools and takes the form of a mould. In this way, many complex shapes can be made. Casting can reduce or, in some cases, eliminate the amount of machining that a part requires. This is most often done in iron, although steel and aluminum can also be cast. |

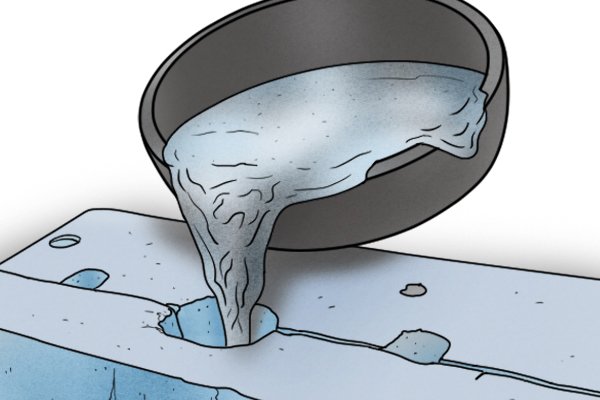

| Heat treatmentHeat treatment and tempering are manufacturing processes used to change the physical properties of metal and other materials. Heat treatment consists in heating the metal to a very high temperature and then hardening it (rapid cooling). This increases the hardness of the metal, but at the same time makes it more brittle. |

| temperTempering is carried out after heat treatment and also includes heating the metal, but to a lower temperature than required during heat treatment, followed by slow cooling. Hardening reduces the hardness and brittleness of the metal, increasing its toughness. By controlling the temperature to which the metal is heated during tempering, the final balance between hardness and toughness of the metal can be changed. |

| ExtrusionExtrusion is an injection molding manufacturing technique in which a material is formed by a punch that forces metal through a die. The matrix has a shape that provides the desired cross-sectional shape of the finished workpiece. Aluminum is by far the most common material used in extruded manufacturing. |

Granite smooth edges | |

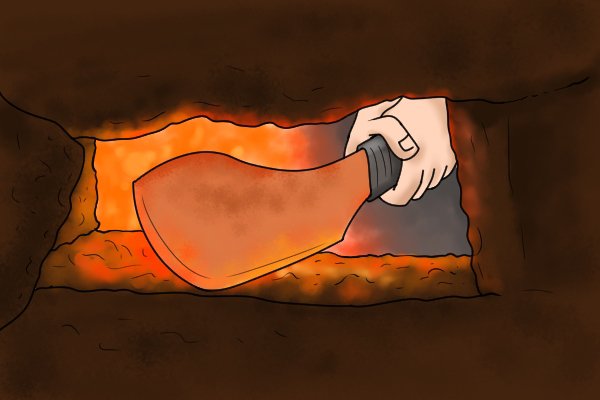

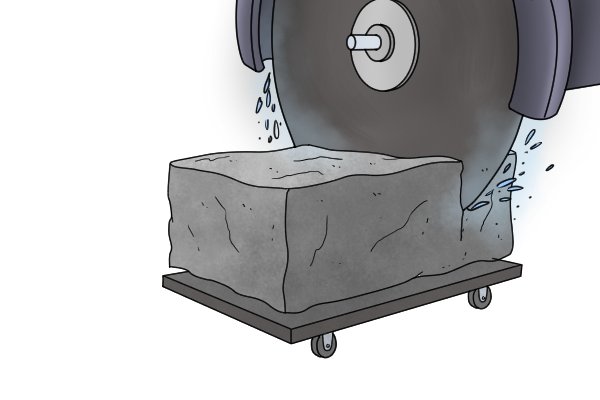

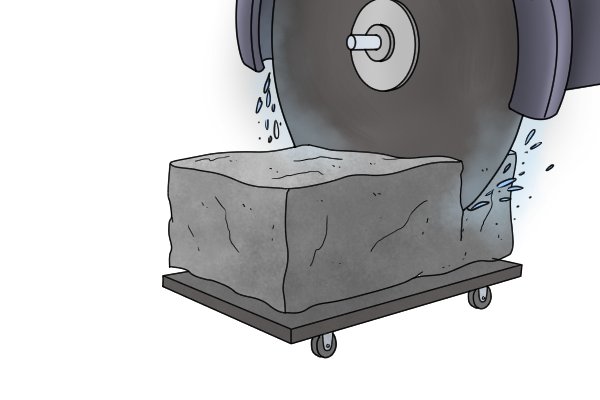

| The engineer's granite rulers are first roughly cut from a large block of granite. This is done with large water-cooled saws. Once the overall shape is achieved, the finish and precision required for use as an engineering ruler is achieved by grinding, scraping, or lapping. |

| GrindingGrinding is the process of using a bonded grinding wheel made up of abrasive particles to remove material from a workpiece. The grinding wheel is a disk that rotates at high speed and the workpiece passes along the side face or surface of the circle. Grinding can be done with discs with grit size from 8 (coarse) to 250 (very fine). The finer the grain size, the better the surface quality of the workpiece. |

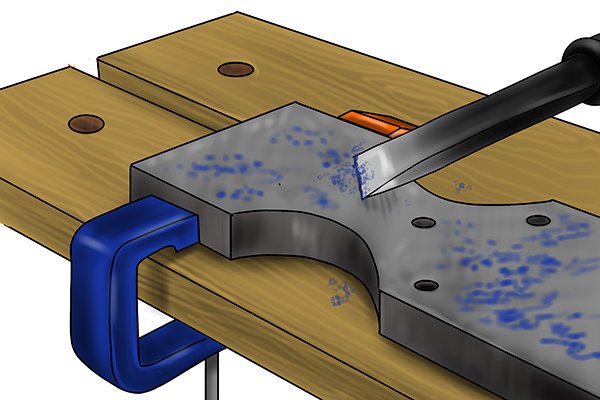

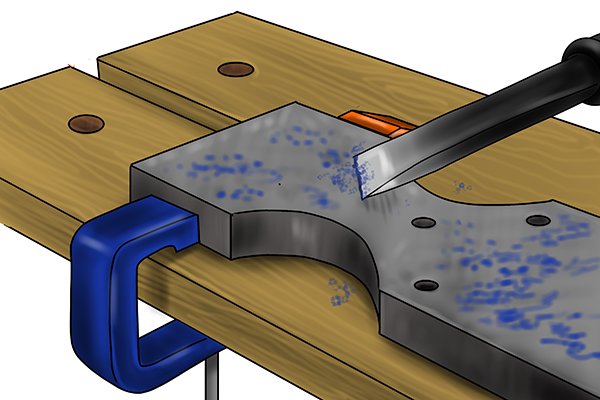

| TrimmingGrinding is a process in which the surface of a workpiece is skimmed off projections to obtain a flat finished surface. Grinding can be done on any metal part that requires a flat surface. |

| LappingLapping is a finishing process used in manufacturing to produce a smoother, more even surface on the finished product. Lapping involves a lapping compound consisting of abrasive particles and oils that are placed between the surface of the workpiece and the lapping tool. Then the lapping tool is moved over the surface of the workpiece. |

| The abrasive nature of the lapping paste erases imperfections in the surface of the workpiece and provides a precise and smooth finish. The most common types of abrasives used in lapping are aluminum oxide and silicon carbide, with grit sizes ranging from 300 to 600. |

Sanding, scraping or lapping? | |

| Grinding does not give such a smooth surface as lapping or sanding. Scouring can only be performed on metal blanks, so it cannot be used to produce granite straight edges. The size of the straight edge will determine whether scraping or lapping produces a better quality straight edge. As a general rule, scraping is more accurate than lapping long lengths, but the only way to tell for sure which ruler will be more accurate is to look at the tolerances of the engineering ruler manufacturers you plan to purchase. |