How does an electric car battery work?

Content

A lithium-ion battery powers any type of electric vehicle. From the outset, it has established itself as a reference technology in the electric vehicle market. How it works? The specialists of the IZI by EDF network will provide you with updated information on the operation, characteristics, advantages and disadvantages of an electric vehicle battery.

Summary

How does an electric vehicle battery work?

If a diesel locomotive uses gasoline or diesel as energy, then this does not apply to electric vehicles. They are equipped with a battery with different autonomy, which must be charged at the charging station.

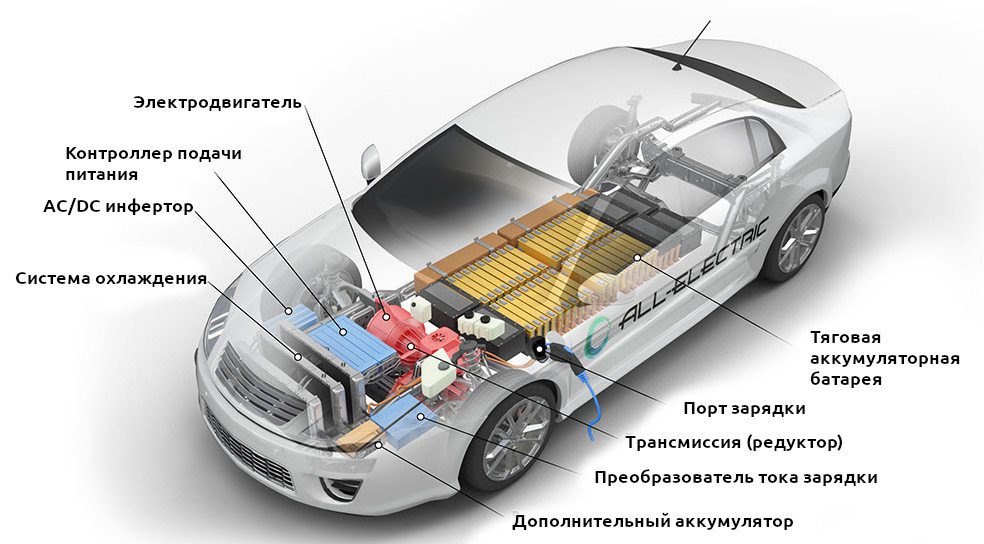

Any electric vehicle is actually equipped with several batteries:

- Additional battery;

- And a traction battery.

What is their role and how they work?

Additional battery

Like a thermal imager, an electric vehicle has an additional battery. This 12V battery is used to power car accessories.

This battery ensures the correct operation of various electrical equipment, such as:

- Electric windows;

- Radio ;

- Various sensors of an electric vehicle.

Thus, a malfunction of the auxiliary battery of an electric vehicle can cause certain breakdowns.

Traction battery

The central element of an electric vehicle, the traction battery, plays an essential role. Indeed, it stores charged energy in the charging station and provides power to the electric motor while traveling.

The operation of a traction battery is quite complex, so this element is one of the most expensive components of an electric vehicle. This cost is also currently hampering the development of electromobility around the world. Some dealers offer a traction battery rental agreement when purchasing an electric vehicle.

The lithium-ion battery is by far the most widely used type of battery in electric vehicles. Due to its durability, performance and safety level, it is truly the reference technology for most manufacturers.

However, there are different types of batteries for electric vehicles:

- Nickel cadmium battery;

- Nickel-metal hydride battery;

- Lithium battery;

- Li-ion battery.

Summary table of the benefits of different batteries for electric vehicles

| Different types of batteries | Advantages |

| Cadmium nickel | Lightweight battery with excellent service life. |

| Nickel metal hydride | Lightweight battery with low pollution and high energy storage capacity. |

| Lithium | Stable charging and discharging. High rated voltage. Significant mass and volumetric energy density. |

| Lithium ion | High specific and volumetric energy. |

Summary table of the disadvantages of various batteries for electric vehicles

| Different types of batteries | Disadvantages |

| Cadmium nickel | Since the toxicity level of cadmium is very high, this material is no longer used. |

| Nickel metal hydride | The material is expensive. The cooling system is needed to compensate for the temperature rise in proportion to the load. |

| Lithium | Lithium recycling is not yet fully mastered. There should be automated power management. |

| Lithium ion | Flammability problem. |

Battery performance

The power of the electric motor is expressed in kilowatt (kW). On the other hand, a kilowatt hour (kWh) measures the energy that an electric vehicle's battery can deliver.

You can compare the power of a heat engine (expressed in horsepower) with the power of an electric motor expressed in kW.

However, if you want to invest in an electric vehicle with the longest battery life, you will need to turn to kWh metering.

Battery life

Depending on the model of your electric vehicle, its range can be on average from 100 to 500 km. Indeed, a low battery is sufficient for simple day-to-day use of an electric vehicle to drive children to school or to work nearby. This type of transport is cheaper.

Apart from the entry-level or mid-range models, there are also high-end models that are much more expensive. The price of these cars is largely influenced by the performance of the battery.

However, this type of electric vehicle can travel up to 500 km depending on your driving style, type of road, weather conditions, etc.

In order to preserve the autonomy of your battery on a long journey, the professionals of the IZI by EDF network advise you, in particular, to choose flexible driving and avoid too fast acceleration.

Battery recharge time

The professionals of the IZI by EDF network will take care, in particular, of installation of charging stations for electric vehicles ... Discover all the existing battery charging solutions for your electric vehicle with:

- Household socket 220 V;

- Wallbox fast charging socket;

- And a fast charging station.

Household socket 220 V

At home, you can install a household outlet for 220 V. Charging time is from 10 to 13 hours. You can then charge your car overnight to use it throughout the day.

Wallbox fast charging socket

If you choose the fast charging socket, also called the Wallbox, the charging time will be shortened:

- For 4 hours in version 32A;

- For 8 or 10 hours in the 16A version.

Fast charging station

In condominium parking lots or in supermarket and business parking, you can also charge your car at the fast charging station. The cost of this device is, of course, the highest.

However, the battery charging time is very fast: it takes 30 minutes.

Summary table of prices for equipment for charging batteries of electric vehicles

| Battery charging equipment type | Price (excluding installation) |

| Fast charging connector | About 600 euros |

| Fast charging station | About 900 € |

How does a lithium-ion battery work?

The principle of operation of this type of battery is complex. Electrons circulate inside the battery, creating a potential difference between the two electrodes. One electrode is negative, the other is positive. They are immersed in an electrolyte: a liquid with ionic conduction.

Discharge phase

When the battery powers the vehicle, the negative electrode releases the stored electrons. They are then connected to the positive electrode via an external circuit. This is the discharge phase.

Charging phase

The opposite effect occurs when the battery is charged in a charging station or a compatible reinforced electrical outlet. Thus, the energy transferred by the charger transfers the electrons present in the positive electrode to the negative electrode.

BMS batteries: definition and operation

The BMS (Battery Management System) software controls the modules and elements that make up the traction battery. This management system allows you to monitor the battery and optimize battery life.

When the battery fails, the same happens with the BMS. However, some EV manufacturers offer a BMS reprogramming service. Thus, a soft reset can take into account the state of the battery at time T.

How reliable is an electric car battery?

The lithium-ion battery is renowned for its reliability. However, be careful, the charging mode, in particular, may affect its durability. In addition, battery life and performance are degraded over time in all cases.

When an electric car breaks down, the cause is very rarely the battery. Indeed, in winter, you will quickly realize that your electric car has no problems starting, despite the cold, unlike a diesel locomotive.

Why do lithium-ion batteries deteriorate over time?

When an electric vehicle travels for many kilometers, the performance of the battery slowly degrades. Then two factors are visible:

- Reduced battery life;

- Longer battery charging time.

How quickly does an electric vehicle battery age?

Various factors can affect the aging rate of a battery:

- Storage conditions for an electric vehicle (in a garage, on the street, etc.);

- Driving style (with an electric car, green driving is preferable);

- Charging frequency at fast charging stations;

- Weather conditions in the area you drive most often.

How to optimize the battery life of an electric vehicle?

By taking into account the factors mentioned above, the service life of the traction battery can be optimized. At any time, the manufacturer or a trusted third party can diagnose and measure the SOH (health status) of the battery. This measurement is used to assess the condition of the battery.

SOH compares the maximum battery capacity at the time of the test with the maximum battery capacity when it was new.

Recycling: second life of an electric vehicle battery

In the electric vehicle sector lithium-ion battery disposal issue in electric vehicles remains a major problem. Indeed, if an EV is cleaner than a diesel locomotive (a hydrocarbon production problem) because it uses renewable energy sources, electricity, lithium recovery and recycling is a problem.

Ecological problems

An electric vehicle battery can contain several kilograms of lithium. Other materials are used such as cobalt and manganese. These three different types of metals are mined and processed for use in battery construction.

Lithium

Two-thirds of the lithium resources used in the development of electric vehicle batteries come from the salt deserts of South America (Bolivia, Chile and Argentina).

The extraction and processing of lithium requires a large amount of water, resulting in:

- Drying of groundwater and rivers;

- Soil pollution;

- And environmental disruptions, such as an increase in poisoning and serious diseases of the local population.

Cobalt

More than half of the world's cobalt production comes from Congolese mines. The latter stand out especially in relation to:

- Safety conditions for mining operations;

- Exploitation of children for the extraction of cobalt.

Delay in the recycling sector: explanations

If the lithium-ion battery has been sold since 1991 in the consumer electronics sector, recycling channels for this material began to develop much later.

If lithium was not initially recycled, then this was mainly due to:

- About its great availability;

- Low cost of its extraction;

- Collection rates remained fairly low.

However, with the rise of electromobility, supply needs change at a rapid pace, hence the need for an efficient recirculation channel. Today, on average, 65% of lithium batteries are recycled.

Lithium Recycling Solutions

Today, there are few obsolete electric vehicles compared to diesel locomotives. This enables almost complete disassembly of vehicles and used battery components.

Thus, lithium as well as aluminum, cobalt and copper can be collected and recycled.

Undamaged batteries follow a different circuit. Indeed, just because they sometimes no longer generate enough power to provide proper performance and range for drivers, that doesn't mean they are no longer working. Thus, they are given a second life. They are then used for stationary use:

- For storage of renewable energy sources (solar, wind, etc.) in buildings;

- For powering fast charging stations.

The power sector has yet to innovate to find alternatives to these materials or to obtain them in other ways.

Installing an electric car charging station