How Generator / Components Works

Content

Everyone knows, or almost knows, that a generator is used to provide electricity to the needs of a car.

However, how is electricity produced? How can a heat engine generate current?

In fact, it is a physical principle, as old as the world, or rather as old as physics, since man discovered that by rotating a magnet in a coil of copper wire, he produces electricity. We may get the impression that we are living in a very technological era, but we have yet to find anything better than this stupid system, like everyone else ...

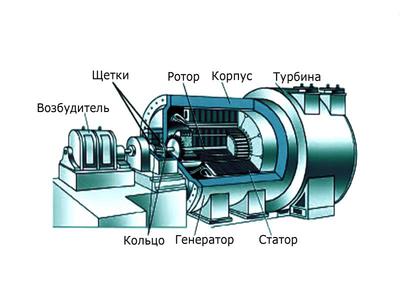

Simplified diagram

conceptual

The engine is off, the magnet does not move and absolutely nothing happens ...

The engine is on,

magnet starts to turn, which moves electrons present at copper atoms (electrons are like skin covering atoms). it a magnetic field magnet that animates them. Then we have a closed circuit in which electrons walk in circles, then we have electricity. This principle is the same for nuclear power plants, thermal power plants, or even hydroelectric power plants.

A heat engine spins an (electro)magnet in a coil, which then produces electricity. The battery receives it and simply stores it in chemical form. When the alternator is no longer running (for various reasons) it no longer charges the battery and the only way to notice this is to see the battery warning light come on when the engine is running (stopped with the ignition on). This is fine) .

Components

Rotor

The latter (rotor for rotation), therefore, can be a permanent magnet or modular (electromagnet "dosed", sending more or less excitation current, design of modern versions). It rotates and is connected to the crankshaft by an accessory drive belt. Therefore, it is associated with bearings that can wear out quickly if the belt is too tight (with the noise of a key).

Brooms / Carbon

In the case of an electrically powered rotor (no permanent magnet), it is necessary to be able to power the rotor while it spins on its own ... A simple electrical connection is not enough (the wire will eventually wind around itself). myself!). As a result, as in the starter, there are coals whose role is to provide contact between two rotating moving elements. As it wears out, contact may be lost and the generator will stop working.

stator

The stator, as the name suggests, is static. In the case of a three-phase alternator, we will have a stator made up of three coils. Each of them will generate an alternating current when the magnet passes through the rotor because its electrons will move due to the magnetic force induced by the magnet.

Voltage regulator

Since modern alternators have an electromagnet in their center, we can modulate the current, making it more or less active (the more we supply it, the more it becomes a powerful magnet). Therefore, it is sufficient to control the current supplied to the stator by the computer in order to limit the power coming from the stator coils.

The voltage obtained after regulation should normally not exceed 14.4 V.

Diode bridge

It rectifies current and therefore converts alternating current (coming from the alternator) to direct current (for the battery). We use an ingenious assembly of several diodes here, knowing that the latter can only be crossed in one direction (hence, according to jargon, there is a direction of passage and a direction of blocking). The diode only allows current to flow from + to -, but not vice versa.

Therefore, when we apply alternating current to the input, there is always direct current at the output.

Battery indicator = generator out of order?

This means that the electrical energy required by the vehicle is currently generated primarily by the battery and not by the alternator. Usually we are aware of the problem when it is necessary to restart the car as the starter, which is electric, has nothing to work with. To learn how to test a generator in 3 minutes, go here.

Load modulation?

The installation of modern alternators is based on an electromagnet, namely at the level of a rotating rotor (thanks to a belt). By modulating the juice injected into the electromagnet, we then modulate its electromagnetic force (more or less intense magnetization), and thanks to this, we can also change the amount of electricity generated by the alternator.

When a lead acid battery is cold, we send more voltage to it because it charges better when it is at a low temperature, and we do the opposite when it is hot.

In addition, modern cars tend to collect milliliters of fuel here and there through various tricks, and turning off the alternator is one of them. In this case, it is enough to cut off the power supply to the magnet if you do not want to have resistive torque at the level of the alternator (which is in direct contact with the engine through the belt), and vice versa, it is fully activated when you want to restore energy when decelerating (when engine braking, we don't care about the loss of torque or kinetic energy). Therefore, it is at this moment that the emergency recovery lamp lights up on the dashboard (of course, all this is controlled by a computer). As a result, the alternators are somewhat intelligent, only activating at the best time and when needed, in order to limit the resistive moment at the level of the accessory belt as often as possible.

Self-priming?

If the rotor is not powered by a battery, then no current will be generated ... However, if everything is spinning at high speeds, a current will still be generated: a kind of magnetic remanence will induce a current in the rotor, which will therefore become a magnet. The rotor should then rotate at about 5000 rpm knowing that the engine speed will be lower (there is a reduction gear due to the different pulley size at the alternator level compared to the pulley. Damper).

This effect is called self-priming and therefore allows the generator to generate current even without energizing it.

Obviously, this problem is irrelevant if we are talking about a permanent magnet generator.

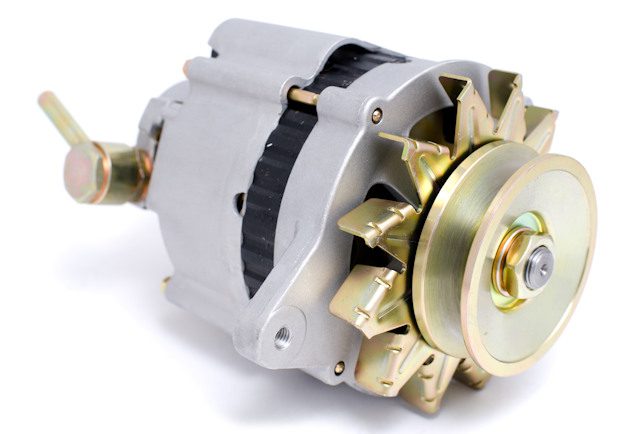

Here is an isolated alternator. The arrow points to the pulley that will be used for its operation.

Here it is in the engine block, we see the belt that drives it.

The belt drives a generator which converts motion into electricity through the assembly described above. Here's the last one in two cars taken at random.

The propeller allows cool generator

In the picture, you can see the copper wire through the slots.

All comments and reactions

Dernier comment posted:

area BEST PARTICIPANT (Date: 2021, 08:26:06)

Today, and for nearly a decade, alternators have been “under control”, meaning that their current production will depend on the use of the vehicle rather than the battery.

Example: During acceleration, the regulated voltage drops to 12,8 V, this is called an energy-saving ballast on the drive wheels.

In the future, it will be the other way around, and we will be able to recover "free" energy.

Then each situation requiring more electricity (air conditioning, steering assistance, anti-lock braking system action) is likely to determine its own value for the control voltage (sometimes more than 15 volts).

To ensure this work, the "optimum charge level" of the battery is set at 80 to 85% and no longer 100% with the regulators pre-calibrated to 14.5 volts.

In order to be able to "recover" the braking energy, the battery does not have to be full ...

These operations require batteries that take it (EFB or AGM), and in any case they will last not 8-10 years, but about 3-5 years, because they eventually sulfate.

A great example of APV is the 2014 Scenic, with frequent battery failures with the need to perform a repair desulfate recharge at least once a month after being used at risk of downtime on the road.

Frequent breakdowns: short city trips and roundabouts, low engine rpm at a roundabout, electric power steering turned on, which drastically lowers the battery level, Christmas tree at the table, in the worst case, engine stalling due to insufficient injection computer power, this is a party !

We've gotten nowhere with this technology other than a few grams of CO2, which will cost the buyer dearly in terms of batteries and all sorts of annoyances.

This reminds me of my 2 volt 6Cv where frequent recharges had to be done.

And I'm not even talking about this grand stop-and-go scam. How many batteries, starters and alternators need to be replaced by 1 liter less than 100 in city driving?

Good luck and good day.

Joël.

Il I. 4 reaction (s) to this comment:

- Ray Kurgaru BEST PARTICIPANT (2021-08-27 14:39:19): Thank you, today I learned a thing or two from you about batteries. 😎

As for stopping and starting, I totally agree with you.

Note: The current battery in my 200 Mercedes C2001 CDI is over 10 years old and still alive.

- Administrator SITE ADMINISTRATOR (2021-08-30 11:09:57): When I see Internet users of this level participating on the site, I tell myself that I have not missed everything ...

Thanks again for sharing all these niceties, it's nice to see some people still have gray matter 😉

- Patrick 17240 (2021-09-02 18:14:14): Hello I have a motor home based on Ducato 160cv euro 6 with start and stop and adblue and while driving my generator only charges at 12,2V, it reaches more than 14 V. deceleration, but it is not obvious that there is always a big deceleration in front of the stage and I get the battery charged at about 12,3 V (voltmeter on the cigarette lighter socket) and Fiat says that is normal ... unplugging the box near the negative terminal of the battery, we get a charge of about a minimum of 12,7, which would be better, but it no longer starts and stops (frivolously), but parasitizes in the radio .. my batteries charge well thanks to the DC-DC installed by the manufacturer .. do you have any solution and do you know about this problem

- jgodard BEST PARTICIPANT (2021-09-03 05:27:22): Привет,

After all, today all cars work in this way. Disabling the battery level sensor is part of the solution and it prohibits stopping and starting, which in my opinion is better for a passenger car (starter, battery or generator malfunction in the middle of the Balkans, not a rag!).

The manufacturer will not provide you with a solution because it is not available in the service department. The computer needs to be reprogrammed so that it detects a battery level closer to 100%, you should currently have 80%.

Only a technician who can change the display will be able to do this, there is a whole community that is very active and recognized professionals who can look at this, but it will of course be offline.

Look around you for "engine reprogramming" and find a "well proven" professional who knows how to modify ECU parameters. If you are on the island of France, I have an address, otherwise they exist throughout the territory. The cost of this type of intervention depends on the ease of access to the cartography, if removing the computer is not necessary, it is ridiculous, otherwise it is about 150 euros.

Now long enough for technicians to be concerned about this problem, you should be able to find a solution. You consume a little more fuel because keeping the battery at an optimal level is low cost, but ridiculous for a vehicle (a few grams of CO2).

Good luck.

Joël.

(Your post will be visible under the comment after verification)

Comments continued (51 Ã 78) >> нажмите здесь

Write a comment

What do you think about inexpensive cars