How to make a do-it-yourself reverse hammer for removing injectors

Content

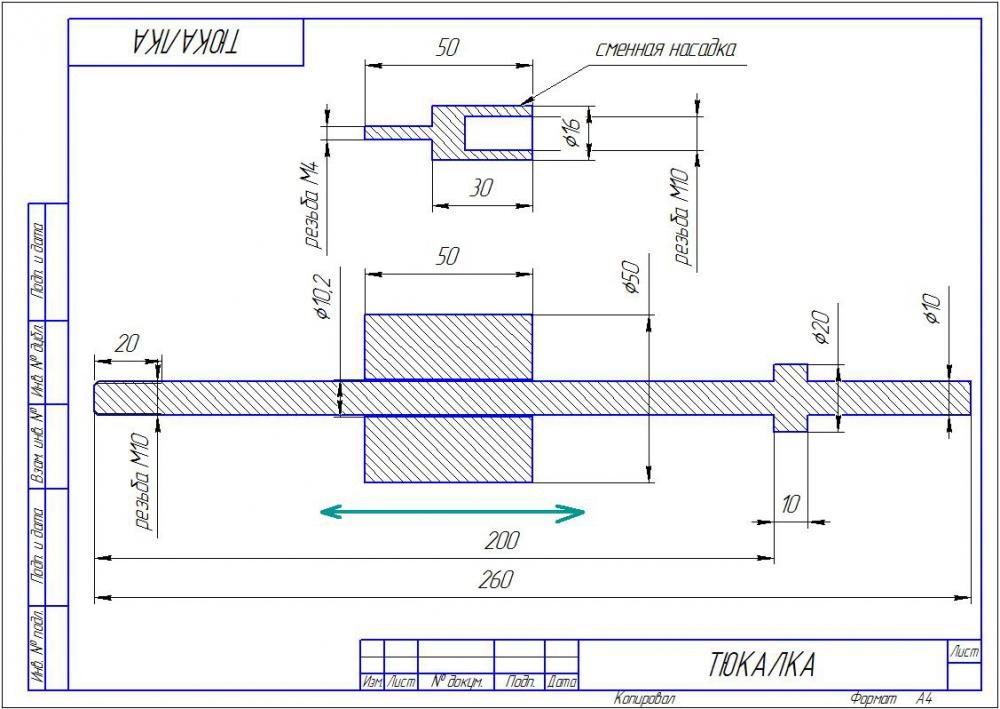

Before designing, decide on the dimensions - usually a length of 50 cm is enough to crawl under the hood and remove the burnt nozzle. The drawing can be found and downloaded on the Internet.

Diesel engine injectors need to be replaced and repaired. It is not difficult to restore the parts, the question may arise with how to dismantle them. Auto repair shops use a special tool, the price of which starts from 30 thousand rubles. Therefore, to remove injectors with their own hands, drivers often make a reverse hammer. To do this, you need to have locksmith and turning skills, experience with a welding machine, cutting tools.

Do-it-yourself pneumatic diesel injector puller

The nozzles are located in a hard-to-reach place - the well of the cylinder head (cylinder head). From exposure to dirt, moisture, these elements rust and stick firmly to the seat. Screw and hydraulic pullers cope with dismantling, but the parts immediately fall apart in two, become unrepairable.

Pneumatic diesel injector extractor

Drawing hammer for removing nozzles

It's not worth getting started without a drawing. It is necessary to represent the design, structure of the pneumatic hammer, the number of components of the future tool, the sequence of connecting them into a single whole.

Drawing hammer for removing nozzles

Before designing, decide on the dimensions - usually a length of 50 cm is enough to crawl under the hood and remove the burnt nozzle. The drawing can be found and downloaded on the Internet. Having collected the necessary components, knowing the principle of operation, you will independently make a drawing for your exclusive reverse hammer and remove the nozzles without dismantling the cylinder head.

Materials and Tools

From power tools, you will need a powerful auto-compressor with a capacity of 250-300 l / min, a grinder, a pneumatic chisel. From the latter, already at the preparatory stage, remove the anther, retaining ring and bushing with a spring: they will no longer be needed.

To make a do-it-yourself reverse hammer for removing injectors, you will also need:

- hose fitting;

- hacksaw for metal;

- gas wrenches and wrenches;

- calipers.

Don't forget the air hoses for the compressor.

Instruction for manufacturing

You have already removed unnecessary parts from the pneumatic chisel.

Instruction for manufacturing

Then you can make a reverse hammer for injectors with your own hands in the steps:

- Clamp the chisel in a vice, unscrew the cylinder from the body.

- Remove the piston from the removed part, followed by the air valve.

- Outside the cylinder from the front cut, cut the thread for the plug.

- Unscrew the sleeve for the fitting from the chisel handle, cut the body into 2 parts.

- Measure all the details of the inside of the case: thread, air hole location, other parameters.

- Turn another cylindrical body on a lathe. It is necessary that its inner surface matches the sawn part.

- Next, on the machine, make a shank outside the back wall - a rod of 5 cm and a diameter of 1,5 cm.

- Turn the plug so that the internal threads match the external threads on the cylinder.

- Harden the body and plug for strength.

- Weld a sleeve over the air valve.

- In the end of the cylinder, place the tail cut off from the chisel for pneumatic tools.

- Install the piston inside the cylinder.

- Screw the wide end of the cylinder into the new body.

- Insert the already prepared shank of the chisel into the other part, tighten the plug (insure the part from unwinding with the fixing bolt).

- Screw the fitting over the air hole through the adapter, fasten the air duct from the compressor to it.

Do-it-yourself reverse hammer for injectors is ready to go. The tool will also come in handy for removing the bearings.