How to install aftermarket springs

Content

Swapping stock springs for aftermarket springs can have a huge impact on your vehicle. Whether you're aiming for a sporty feel or even just a different look by lowering your car, new springs can make your car look more attractive and…

Swapping stock springs for aftermarket springs can have a huge impact on your vehicle. Whether you're after a sporty feel or even just a different look by lowering your car, new springs can make your car unique.

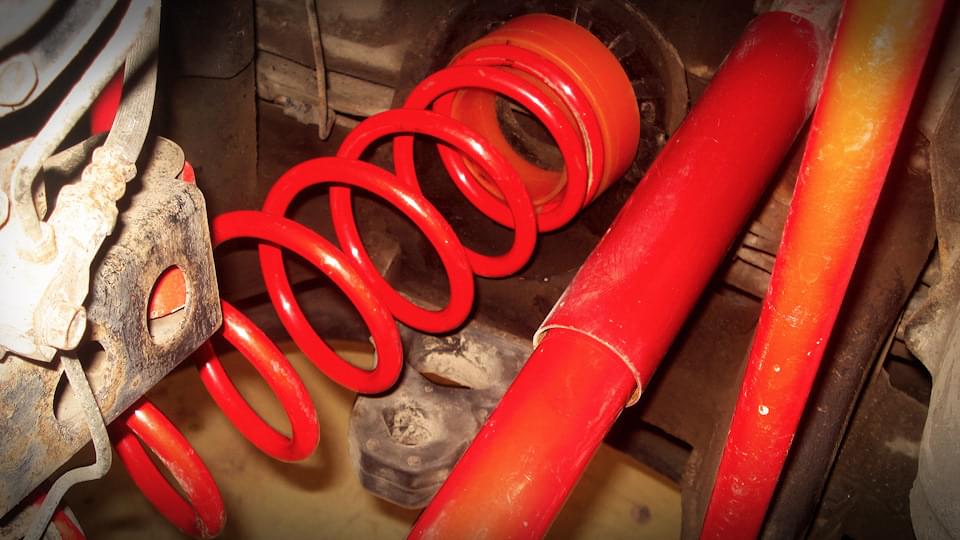

The only fancy tool you'll need for this job is spring compressors. These are special clamps that compress the spring and allow you to remove and install them. Generally, if you don't want to buy them, you can rent them from your local auto parts store. Do not use other types of clips on the springs or you may damage them. Even small scratches and dents in a spring can seriously reduce its overall strength, so use only spring compressors.

Make sure you buy the correct style springs for your make and model. Also, keep in mind that lowering the car too much can cause the tires to rub against the wheel arches, so it's worth taking a few measurements.

Part 1 of 4: Removing the Front Springs

Necessary materials

- Hex wrench

- Switch

- Hammer

- percussion pistol

- socket

- Jack stands

- New springs, usually as a kit

- ratchet

- Ceiling rosette

- Spring compressors

- Wrench

screwdrivers

Functions: It is highly recommended to use an impact gun for this job as you will have to remove quite a few bolts. Using an impact gun is faster and won't tire you out twisting wrenches all day long. Also, if you're using an impact gun, you won't need a hex wrench.

FunctionsA: Look in your vehicle repair manual or online to find the dimensions of all nuts and bolts as they vary by make and model.

Step 1: Jack up the car. To remove the wheels and access the spring and damper, you will need to raise the car.

On a flat, level surface, jack up the vehicle and lower it onto several stands.

- Functions: Be sure to loosen the lug nuts with a jackhammer or impact gun before lifting the wheels off the ground. Otherwise the wheels will just spin in place when you try to loosen the nuts later.

Step 2: remove the wheels. Most spring compression kits come with four springs, so remove all four wheels.

If there are only two springs in the kit or you don't have enough jacks, you can make two wheels at the same time.

Step 3: Place a jack under the lower control arm.. Starting at one of the front wheels, use a jack to slightly raise the entire wheel hub.

This will help support the lower control arm so it doesn't fall off later when you remove a few nuts and bolts.

Step 4: Remove the bottom bolts that secure the shock to the wheel hub.. Use a wrench to hold one side while you unscrew the other with a ratchet or impact gun.

The bolt can sometimes be difficult to remove once the nut has been removed, but you can use a hammer to tap it lightly.

Step 5: Remove the fixing nuts at the top of the rack.. Remove the nuts that secure the top of the strut to the car body.

If you don't have an impact gun, you may need a hex and hex wrench to loosen the top mount.

Step 6: Remove the Stand. By removing the bottom and top mounting bolts, you can remove the entire rack assembly.

You can lower the jack a little to make the control lever drop. It should come out of the top of the wheel hub without too much trouble, but you may need to tap the hub with a hammer to dislodge the joint.

Step 7: Compress the Springs. With the entire strut assembly removed, you will need to compress the springs to relieve pressure so you can remove the top lock nut.

Use two spring compressors, each on opposite sides of the spring, and progressively tighten each until you can freely rotate the top mount. Having an impact gun for this part greatly simplifies and speeds up the work.

- A warning: If you do not compress the springs before loosening the lock nut, the pressure of the springs will cause the top part to come off and may injure you or those around you. Always compress the springs before removing the lock nut.

Step 8: Remove the lock nut. With compressed springs, you can safely remove the lock nut.

Step 9: Remove all mounting hardware. This is usually a rubber damper, a bearing that allows the post to rotate, and an upper seat for the spring. Remove each of these parts.

Be sure to save all the parts and lay them out so you can put them on the new springs the same way.

Step 10: Remove the Spring from the Post. After removing the spring from the strut, decompress the spring compressors so that they can be used to install new springs later.

Step 11: Inspect All Mounting Parts. Check that none of the mounting elements show signs of damage.

Check that the rubber damper has not cracked or become brittle and that the bearing is still free to rotate.

Part 2 of 4: Installing the front springs

Step 1: Compress New Springs. You will not be able to tighten the lock nut without first compressing the springs.

As before, use two spring compressors, each on opposite sides of the spring, and alternate sides to compress the spring evenly.

Step 2: Install the new spring on the strut.. Make sure the bottom of the spring fits into the groove in the base of the strut when you install the spring onto it.

This helps prevent the spring from rotating.

- Functions: Use the label on the spring to make sure you installed it correctly. You should be able to read the letters on the spring once it's installed, so use those to make sure it's oriented correctly.

Step 3: Reinstall Mounting Parts. Be sure to replace the mounting parts in the same way you removed them. Otherwise, the node may have problems with rotation.

Step 4: Replace the lock nut. Start tightening the lock nut by hand.

If you can no longer turn it by hand, use a wrench or impact gun to tighten it further.

Remove the compression springs to fully tighten the lock nut to the correct torque.

Step 5: Install the stand back into the mounts.. You are now ready to put the strut back into the car with the new spring.

- Functions: Use a jack to support the weight of the suspension and lift the entire assembly to line up the holes.

Step 6: Replace the top mounting nut. Align the top of the stand with its mount. Once the screws are aligned, begin installing the mounting nut or nuts by hand to support the weight of the rack while you level the bottom.

Step 7: Replace the bottom mounting bolts. Align the bottom mounting holes and insert the bottom mounting bolts.

Tighten them to the required torque.

Step 8: Tighten the top nuts. Go back to the top mount and tighten the nuts to the correct torque.

Step 9: Repeat with the other side. Replacing the spring on the other side will be the same process, so just repeat steps 1 and 2 on the other front spring.

Part 3 of 4: Removing the rear springs

Step 1: Support the rear wheel hub. As with the front end, you will need to support the wheel hubs so they don't fall off as we remove the bolts on the shock.

- Functions: Since we have already finished with the front suspension, you can put the front wheels back and use the jacks to support the rear.

Step 2: Loosen the nuts on the shock absorber.. You can remove the nuts at the top that secure the shock to the body, or the bolt at the bottom of the shock that connects it to the control arm.

Step 3: Pull out the spring and all fasteners.. Remove the spring and remove its fasteners.

There should be a rubber damper and maybe another piece to help seat the spring underneath.

Be sure to set them aside to transfer to a new spring later. Inspect these parts also for damage.

Part 4 of 4: Installing the rear springs

Step 1: Install the rubber damper on the new spring.. Make sure you place the rubber damper on the correct side of the spring.

Also install any other fasteners in the order they were on the old spring.

- Functions: As with the front springs, if you can read the lettering on the spring, it is oriented correctly.

Step 2: Place the spring in the lower seat. Install the spring so that it is in place when you lift the hub and reattach the shock.

Step 3: Jack up the wheel hub. To align the shock absorber with the mount, you can jack up the rear wheel hub.

The jack will hold the hub while you tighten the nuts by hand.

When lifting the hub and leveling the shock, make sure the spring is properly seated at the top. There is usually a notch on the frame that prevents the spring from moving. Make sure the rubber damper fits around the notch.

Step 4: Tighten the nuts to the correct torque.. Once everything is aligned and properly positioned, tighten the rear shock nuts to specification.

- A warning: Never overtighten nuts or bolts, as this puts stress on the metal, making it weaker, especially with suspension components that are subjected to heavy impact on a daily basis.

Step 5: Repeat with the other side. Replacing the spring on the other side will be the same process, so just repeat steps 3 and 4 on the other rear spring.

Step 6: Reinstall the wheels. Now that the new springs are in place, you can reattach the wheels.

Make sure they are tightened to the correct torque.

By returning the suspension and wheels, you can also lower the car to the ground.

Step 7: Take a Short Trip. Take the car for a drive to test out the new suspension.

Start with residential streets and take your time. You want the springs and other components to settle before moving faster. If everything seems fine after a few miles, the suspension is set correctly.

Now that the new springs are installed, your car is ready to go to the track or car show. Keep in mind that if you feel abnormal during a test drive, you should stop and have a professional, such as one of AvtoTachki certified technicians, check the components to make sure everything is installed correctly. If you don't feel confident installing new springs yourself, you can also have one of AvtoTachki's technicians replace it.