How to Replace a Leaking Brake Line

Content

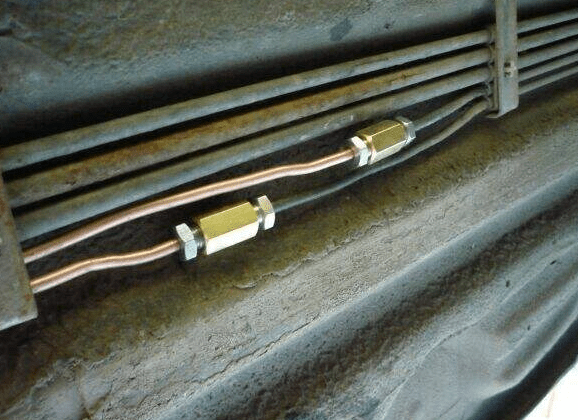

Metal brake lines can rust and should be replaced if they start to leak. Upgrade your line to copper nickel for corrosion protection.

Your brakes are the most important system in your vehicle for your safety. Being able to stop your car quickly and safely will help you avoid collisions. Unfortunately, the environment we live in can wreak havoc on your brake lines and cause them to fail and leak.

Typically, your car's metal brake lines are made from steel to keep costs down, but steel is susceptible to corrosion, especially in winter when salt is often on the ground. If you need to replace your brake line, you should consider replacing it with a copper-nickel one, which is much more resistant to rust and corrosion.

Part 1 of 3: Removing the old row

Necessary materials

- flat screwdriver

- Gloves

- socket

- Jack stands

- Line key

- Pliers

rags

AttentionA: If you're only replacing one line, it may be cheaper and easier to buy a pre-formed line than buying all the DIY tools. Do some evaluation and see which option makes the most sense.

Step 1: Walk on the brake line you are replacing.. Inspect each part of the replacement line to see how and where it is attached.

Remove any panels that are in the way. Be sure to loosen the nuts before jacking up the car if you need to remove the wheel.

Step 2: Jack up the car. On a flat, level surface, jack up the vehicle and lower it on jack stands to work under it.

Block all wheels that are still on the ground so the car cannot roll.

Step 3: Unscrew the brake line from both ends.. If the fittings are rusty, you should spray some penetrating oil on them to make them easier to remove.

Always use a wrench on these fittings to avoid rounding them. Have rags ready to clean up spilled liquid.

Step 4: Plug the end that goes to the master cylinder.. You don't want all the fluid coming out of the master cylinder while we're making a new brake line.

If it runs out of fluid, you will have to bleed the entire system, not just one or two wheels. Make your own end cap from a short piece of tubing and an extra fitting.

Squeeze one end of the tube with pliers and fold it over to form a seam. Put on the fitting and straighten the other end. Now you can screw it to any part of the brake line to keep fluid from leaking out. More about pipe flaring in the next section.

Step 5: Pull the brake line out of the mounting brackets.. You can use a flathead screwdriver to pry the lines out of the clips.

Be careful not to damage any other pipes installed near the brake line.

Brake fluid will flow from the ends of the line. Be sure to remove paint drips as brake fluid is corrosive.

Part 2 of 3: Making a New Brake Line

Necessary materials

- Brake line

- brake line fittings

- Flare Tool Set

- Flat metal file

- Gloves

- Safety glasses

- pipe bender

- Tube cutter

- Deputy

Step 1: Measure the length of the brake line. There will probably be a few bends, so use the string to determine the length and then measure the string.

Step 2: Cut the tube to the correct length.. Give yourself an extra inch or so, as it's hard to bend lines as tight as they come from the factory.

Step 3: Insert the tube into the flaring tool.. We want to file the end of the tube to make it smooth, so lift it up slightly in the mount.

Step 4: File the end of the tube. Preparing the pipe before flaring will ensure a good and durable seal.

Remove any burrs left inside with a razor blade.

Step 5: File the outer edge of the tube for installation.. Now the end should be smooth and without burrs, put on the fitting.

Step 6: Expand the end of the brake line. Place the tube back into the flare tool and follow the instructions for your kit to create the flare.

For brake lines, you will need a double flare or bubble flare depending on the vehicle model. Do not use brake line flares as they cannot withstand the higher pressure of the brake system.

- Functions: Use some brake fluid as a lubricant when forming the end of the pipe into a flare. So you don't have to worry about any contaminants getting into your braking system.

Step 7: Repeat steps 3 to 6 on the other side of the tube.. Don't forget to try on or you'll have to start all over again.

Step 8: Use a pipe bender to form the correct line.. It doesn't have to be exactly the same as the original, but it should be as close as possible.

This means that you can still secure the line with any clips. The tube is flexible so you can make small adjustments while it's on the machine. Now our brake line is ready for installation.

Part 3 of 3: New Line Installation

Step 1: Install the new brake line in place. Make sure it reaches both ends and still fits into any clips or fasteners.

If the line is not secured to any of the mounts, it may be bent while the vehicle is moving. A kink in the line will eventually lead to a new leak and you will have to replace it again. You can use your hands to bend the line to make small adjustments.

Step 2: Screw Both Sides. Start them by hand so you don't mix anything up, then use an adjustable wrench to tighten them.

Press them down with one hand so you don't overtighten them.

Step 3: Secure the brake line with fasteners.. As mentioned earlier, these bindings keep the line from bending and flexing, so use them all.

Step 4: Bleeding the Brakes. You only need to bleed one or more of the tubes you replaced, but if the brakes are still soft, bleed all 4 tires just to be sure.

Never let the master cylinder run dry or you'll have to start over. Check the connections you made for leaks while bleeding the brakes.

- Attention: having someone pump the brakes while you open and close the exhaust valve makes the job much easier.

Step 5: Put everything back together and put the car on the ground.. Make sure everything is properly installed and the vehicle is securely on the ground.

Step 6: Test drive the car. Before driving, perform a final leak check with the engine running.

Apply the brake sharply several times and check for puddles under the car. If all looks good, test the brakes at low speed in an empty spot before driving into traffic.

With a brake line replacement, you won't have to worry about any leaks for a while. Doing this at home can save you money, but if you need help, ask your mechanic for some helpful advice on the process, and if you notice your brakes aren't working well, one of AvtoTachki's certified technicians will perform an inspection.