How to make the VAZ 2107 radiator fan work

Content

Forced airflow of the cooling radiator is used in all automotive internal combustion engines without exception. This is the only way to avoid overheating of the power plant. That is why it is necessary to periodically check the health of the electrical circuit for turning on the radiator fan.

Cooling fan VAZ 2107

In the power plants of the first "sevens", the radiator fan was installed directly on the water pump shaft. Like the pump, it was driven by a belt drive from the crankshaft pulley. This design was also used on other vehicles at that time. It almost never failed, and it was impossible to overheat the engine with it. However, she had one drawback. The constantly cooled power unit warmed up very slowly. That is why AvtoVAZ designers changed the principle of forced airflow, replacing a mechanical fan with an electric one, moreover, with automatic switching on.

Why do you need an electric fan

The fan is designed for forced airflow of the cooling radiator. During the operation of the power plant, the liquid refrigerant through the opened thermostat enters the radiator. Passing through its tubes, equipped with thin plates (lamellas), the refrigerant cools down due to the heat exchange process.

When the car is moving at speed, the oncoming air flow contributes to heat transfer, but if the car is stationary for a long time, or drives slowly, the coolant does not have time to cool down. At such moments, it is the electric fan that saves the engine from overheating.

Device design

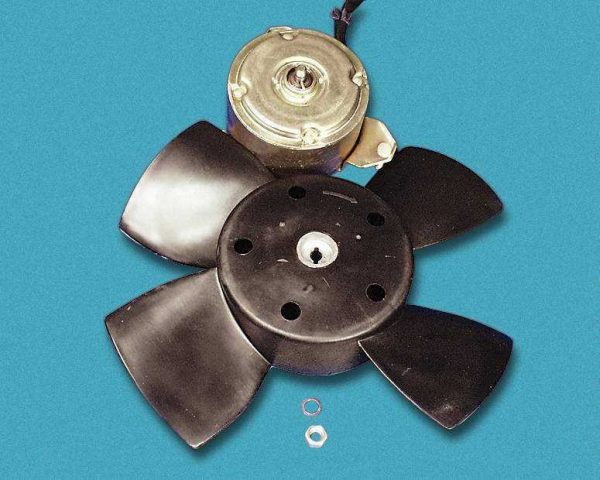

The radiator fan consists of three main elements:

- DC motor;

- impellers;

- framework.

The fan consists of an electric motor, an impeller and a frame

The fan consists of an electric motor, an impeller and a frame

The motor rotor is equipped with a plastic impeller. It is she who, rotating, creates a directed air flow. The engine of the device is installed in a metal frame, with which it is attached to the radiator housing.

How an electric fan turns on and works

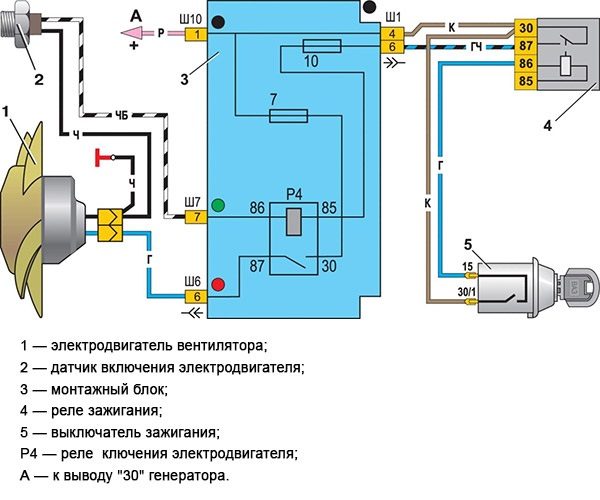

The process of turning on the fan for carburetor and injection "sevens" is different. For the first, a mechanical temperature sensor mounted in the lower part of the right tank of the cooling radiator is responsible for its inclusion. When the engine is cold, the sensor contacts are open. When the temperature of the refrigerant rises to a certain level, its contacts close, and voltage begins to be applied to the brushes of the electric motor. The fan will continue to operate until the coolant cools down and the sensor contacts open.

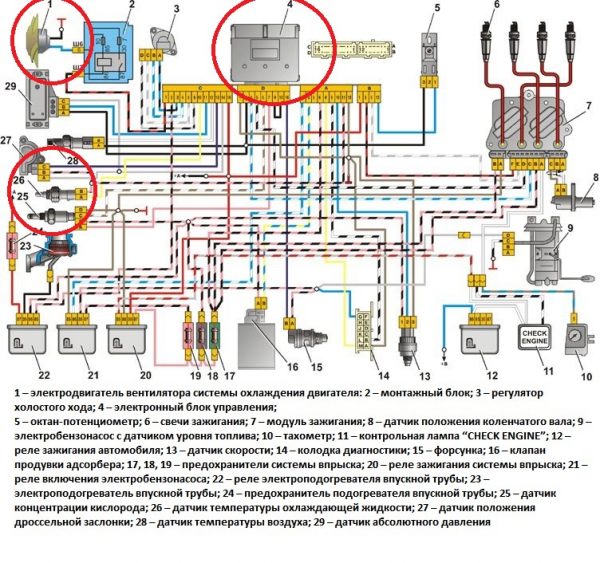

In the injector "sevens" the electric fan switching circuit is different. Here everything is controlled by an electronic control unit. The initial signal for the ECU is information coming from a sensor installed in the pipe leaving the engine (near the thermostat). Having received such a signal, the electronic unit processes it and sends a command to the relay responsible for turning on the fan motor. It closes the circuit and supplies electricity to the electric motor. The unit will continue to operate until the temperature of the refrigerant drops.

In both carburetor and injection "sevens", the electric fan circuit is protected by a separate fuse.

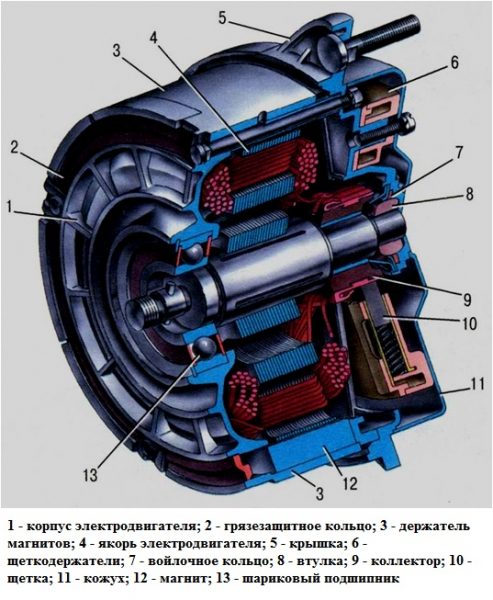

Fan motor

The electric motor is the main unit of the device. The VAZ 2107 used two types of engines: ME-271 and ME-272. According to the characteristics, they are almost identical, but as for the design, it is somewhat different. In the ME-271 engine, the body is stamped, i.e., non-separable. It does not need periodic maintenance, however, in the event of a malfunction, it can only be replaced.

The device and characteristics of the fan motor

Structurally, the motor consists of:

- housing;

- four permanent magnets glued around the circumference inside the case;

- anchors with winding and collector;

- brush holder with brushes;

- ball bearing;

- support sleeve;

- back cover.

The ME-272 electric motor also does not need maintenance, but unlike the previous model, if necessary, it can be partially disassembled and attempted to be restored. Disassembly is carried out by unscrewing the coupling bolts and removing the rear cover.

In practice, repair of the electric fan is impractical. Firstly, you can only buy used spare parts for it, and secondly, a new device assembled with an impeller costs no more than 1500 rubles.

Table: main technical characteristics of the electric motor ME-272

| Features | Indicators |

| Rated voltage, V | 12 |

| Rated speed, rpm | 2500 |

| Maximum current, A | 14 |

Cooling fan malfunctions and their symptoms

Given that the fan is an electromechanical unit, the operation of which is provided by a separate circuit, its malfunctions can manifest themselves in different ways:

- the device does not turn on at all;

- the electric motor starts, but runs constantly;

- the fan starts running too early or too late;

- during operation of the unit, extraneous noise and vibration occur.

The fan does not turn on at all

The main danger posed by the breakdown of the cooling fan is overheating of the power plant. It is important to control the position of the arrow of the temperature indicator sensor and feel the moment the device is turned on. If the electric motor does not turn on when the arrow reaches the red sector, most likely there is a malfunction of either the device itself or its circuit elements. These breakdowns include:

- failure of the armature winding, wear of the brushes or motor collector;

- sensor malfunction;

- break in the electrical circuit;

- blown fuse;

- breakdown of the relay.

Continuous fan operation

It also happens that the motor of the device turns on regardless of the temperature of the power plant and works constantly. In this case, there may be:

- short circuit in the electric circuit of the fan;

- sensor failure;

- jamming of the relay in the on position.

The fan turns on early, or, conversely, late

Untimely turning on of the fan indicates that the characteristics of the sensor have changed for some reason, and its working element reacts incorrectly to temperature changes. Similar symptoms are typical for both carburetor and injection "sevens".

Extraneous noise and vibration

The operation of the cooling fan of any car is accompanied by a characteristic noise. It is created by an impeller, cutting through the air with its blades. Even merging with the sound of the car engine, in the "seven" this noise is clearly audible even from the passenger compartment. For our cars, it is the norm.

If the rotation of the fan blades is accompanied by a hum, creak or whistle, the front bearing or the support sleeve in the cover may have become unusable. A crack or knock indicates the contact of the impeller with the inner edge of the frame in which the electric motor is installed. Such a malfunction is possible due to deformation or misalignment of the fan blades. For the same reasons, vibration occurs.

Diagnostics and repair

It is recommended to check the fan and its electrical circuit elements in the following order:

- Fuse.

- Relay.

- Electric motor

- Temperature sensor.

Checking the fuse is working

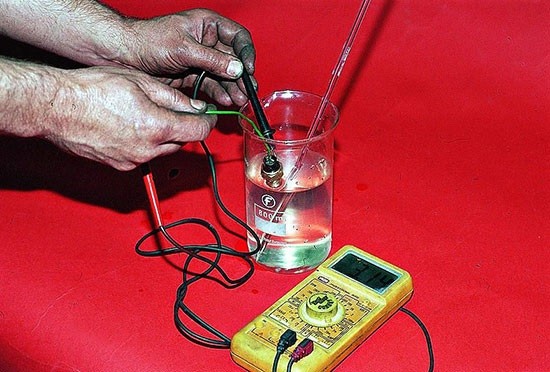

The fuse is usually checked first, as this process is the easiest and does not take much time. For its implementation, only an autotester or a test lamp is required. The essence of diagnostics is to determine whether it passes an electric current.

The fan circuit fuse is installed in the vehicle's mounting block, which is located in the engine compartment. In the diagram, it is designated as F-7 with a rating of 16 A. To check and replace it, you must perform the following work:

- Disconnect the negative terminal from the battery.

- Remove the mounting block cover.

- Find fuse F-7 and remove it from its seat.

F-7 fuse is responsible for the safety of the fan circuit

F-7 fuse is responsible for the safety of the fan circuit - Connect the tester probes to the fuse terminals and determine its serviceability.

- Replace the fuse if the device wire is blown.

A good fuse should carry current.

A good fuse should carry current.

Relay diagnostics

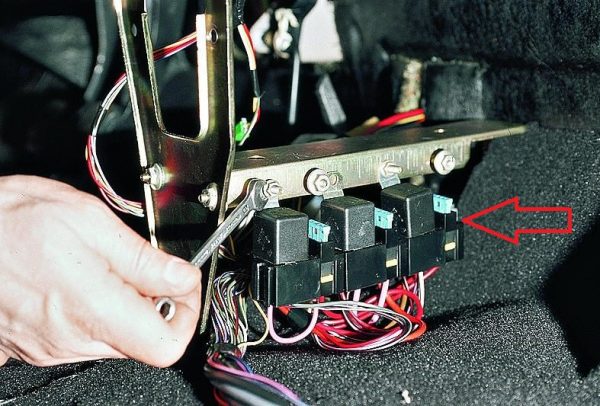

As we have already said, in the injection "sevens" a relay is provided to unload the electrical circuit of the radiator fan. It is installed in an additional mounting block located under the glove box in the passenger compartment and is designated as R-3.

Checking the relay yourself is quite problematic. It is much easier to take a new device and install it in the place of the diagnosed one. If the electric fan turns on when the refrigerant is heated to the desired temperature, then the problem was precisely in it.

Checking and replacing the electric motor

Required Tools:

- voltmeter or multifunctional autotester;

- two pieces of wire;

- socket wrenches on "8", "10" and on "13";

- passatizhi.

The order of work is as follows:

- Disconnect the fan power connector.

- We connect two wires to the contacts of the half of the connector that comes from the electric motor, the length of which should be enough to connect them to the battery terminals.

To test the electric motor, it must be connected directly to the battery.

To test the electric motor, it must be connected directly to the battery. - Connect the ends of the wires to the battery terminals. If the fan does not turn on, you can prepare to replace it.

- If it has worked properly, it is worth checking whether voltage is applied to it.

- We connect the voltmeter probes to the contacts of the other half of the connector (to which voltage is applied).

- We start the engine, close the sensor contacts with a screwdriver (for carburetor cars) and look at the readings of the device. The voltage at the contacts should be equal to what the generator produces (11,7–14,5 V). For injection machines, nothing needs to be closed. It is necessary to wait until the engine temperature reaches the value at which the electronic control unit sends a signal to the relay (85–95 °C) and read the instrument readings. If there is no voltage, or it does not correspond to the set values \uXNUMXb\uXNUMXb(for both types of motors), the cause should be sought in the device circuit.

The voltage at the connector contacts must be equal to the voltage of the on-board network

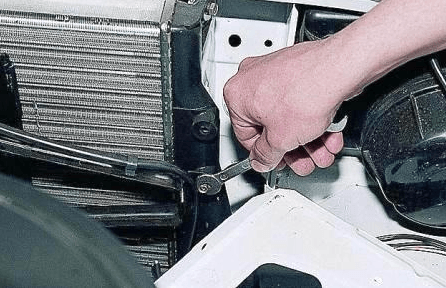

The voltage at the connector contacts must be equal to the voltage of the on-board network - If a malfunction of the electric motor is detected, using the “8” socket wrench, unscrew 2 bolts fixing the fan shroud to the radiator (left and right).

The frame is attached with two screws.

The frame is attached with two screws. - Carefully pull the casing towards you, at the same time releasing the sensor wires from the retainer.

The electric motor is removed together with the frame

The electric motor is removed together with the frame - Using pliers, we compress the petals of the wire sheath. We push the clamps out of the casing.

- Dismantle the fan assembly.

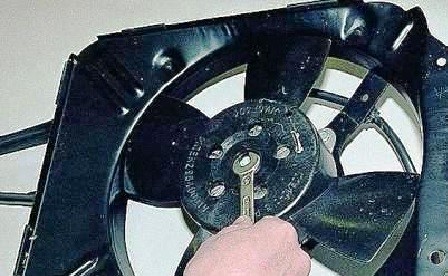

- Holding the impeller blades with your hand, unscrew the nut of its fastening with a socket wrench to “13”.

When unscrewing the nut, the impeller blades must be held by hand

When unscrewing the nut, the impeller blades must be held by hand - Disconnect the impeller from the shaft.

After unscrewing the nut, the impeller can be easily removed from the shaft

After unscrewing the nut, the impeller can be easily removed from the shaft - Using the key to "10", unscrew all three nuts that secure the motor housing to the frame.

The engine is attached with three nuts

The engine is attached with three nuts - We remove the faulty electric motor.

- We install a new device in its place. We assemble in the reverse order.

Diagnostics and replacement of the temperature sensor

The temperature sensors of carburetor and injection "sevens" differ not only in design, but also in the principle of operation. For the former, the sensor simply closes and opens the contacts, while for the latter, it changes the value of its electrical resistance. Let's consider both options.

Carburetor engine

From the tools and means you will need:

- open-end wrench on "30";

- spanner or head on "13";

- ohmmeter or autotester;

- liquid thermometer with a measurement range of up to 100 °C;

- clean container for collecting refrigerant;

- a container with water;

- gas (electric) stove or household boiler;

- dry clean cloth.

The check and replace algorithm is as follows:

- We substitute the container under the plug on the cylinder block of the power plant.

The cork is unscrewed with a key to "13"

The cork is unscrewed with a key to "13" - We unscrew the plug, drain the refrigerant.

Drained fluid can be reused

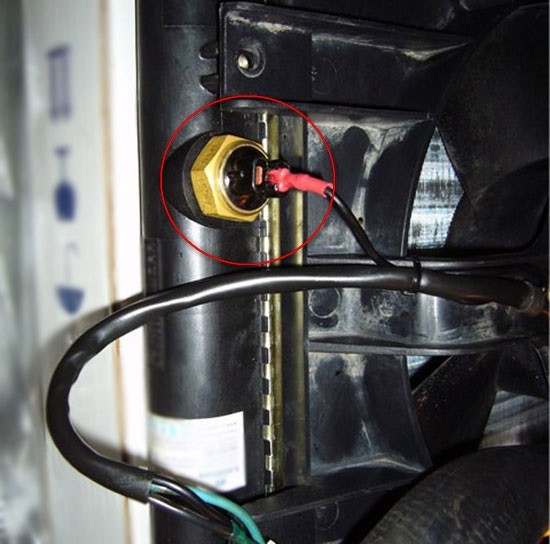

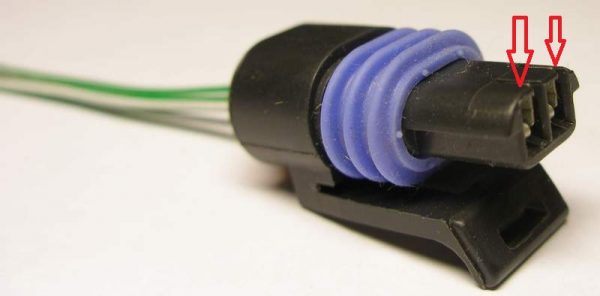

Drained fluid can be reused - Disconnect the connector from the sensor contacts.

Connector can be easily removed by hand

Connector can be easily removed by hand - Using the key to "30" unscrew the sensor.

The sensor is unscrewed with a key to "30"

The sensor is unscrewed with a key to "30" - We connect the ohmmeter probes to the sensor contacts. The resistance between them in a serviceable device should tend to infinity. This means that the contacts are open.

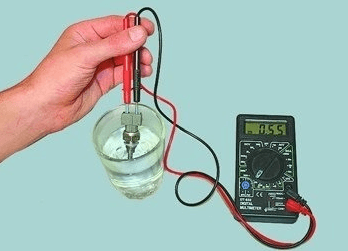

- We place the sensor with the threaded part in a container with water. We do not turn off the probes of the device. We heat water in a container using a stove or boiler.

When water is heated to 85–95 °C, the sensor must pass current

When water is heated to 85–95 °C, the sensor must pass current - We observe the readings of the thermometer. When the water reaches a temperature of 85–95 °C, the sensor contacts should close, and the ohmmeter should show zero resistance. If this does not happen, we change the sensor by screwing a new device in place of the old one.

Video: how to prevent the engine from overheating with a faulty sensor

Injection engine

The injector "seven" has two temperature sensors. One of them works in tandem with a device that shows the temperature of the refrigerant to the driver, the other with the computer. We need a second sensor. As already mentioned, it is installed on the pipe next to the thermostat. To check and replace it, we need:

- autotester or multimeter with the ability to measure voltage and resistance;

- open-end or box wrench to "19";

- liquid thermometer with temperature measurement amplitude up to 100 °C;

- heat-resistant container with water;

- boiler or stove (for heating a container of water);

- clean dry cloth.

The order of work is as follows:

- We find the sensor. Disconnect the connector from its contacts.

The sensor is installed on the pipe next to the thermostat

The sensor is installed on the pipe next to the thermostat - We turn on the ignition.

- We turn on the multimeter or tester in the voltage measurement mode. We connect the probes of the device to the connector contacts. Let's look at the evidence. The device should show approximately 12 V (battery voltage). If there is no voltage, the problem must be sought in the power supply circuit of the device.

Voltage is measured between the connector pins with the ignition on

Voltage is measured between the connector pins with the ignition on - If the device shows a nominal voltage, turn off the ignition and remove the terminal from the battery.

- Using the key on "19", we unscrew the sensor. This may result in a small amount of coolant escaping. Wipe spills with a dry cloth.

The sensor is unscrewed with a key to "19"

The sensor is unscrewed with a key to "19" - We switch our device to the resistance measurement mode. We connect its probes to the sensor contacts.

- We place the sensor with the working part in a container with water.

- We heat the water, observing the change in temperature and resistance. If the readings of both devices do not correspond to those given below, we replace the sensor.

Sensor resistance should change with temperature

Sensor resistance should change with temperature

Table: dependence of the resistance value DTOZH VAZ 2107 on temperature

| Liquid temperature, OS | Resistance, Ohm |

| 20 | 3300 – 3700 Feet |

| 30 | 2200 – 2400 Feet |

| 40 | 2000 – 1500 Feet |

| 60 | 800 – 600 Feet |

| 80 | 500 – 300 Feet |

| 90 | 200 – 250 Feet |

Fan forced on

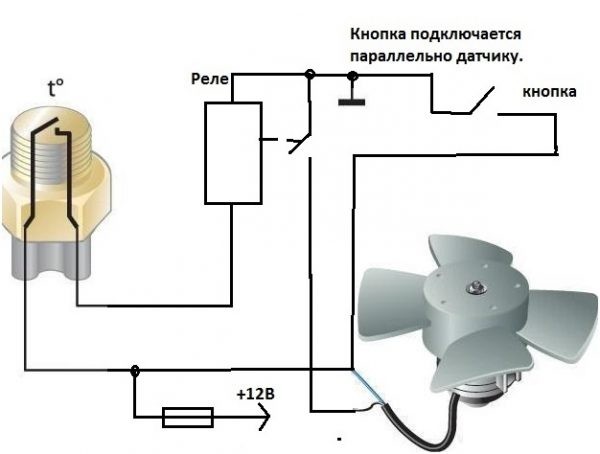

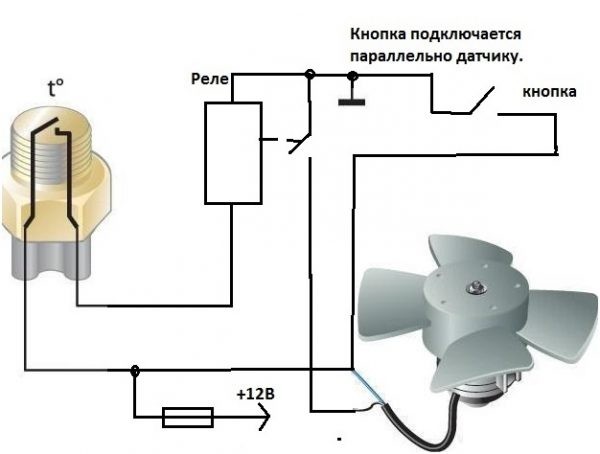

Some owners of the "classics", including the VAZ 2107, install a forced fan button in their cars. It allows you to start the electric motor of the device regardless of the temperature of the refrigerant. Given the fact that the design of the "seven" cooling system is far from ideal, this option can someday help out a lot. It will also come in handy for those drivers who often move along country roads or are forced to stand in traffic jams.

Forced turning on of the fan is appropriate only on carbureted cars. In machines with injection engines, it is better to rely on the electronic control unit and not make any changes to its operation.

Video: forced fan on

Watch this video on YouTube

The easiest way to make the fan turn on at the request of the driver is to bring two wires from the temperature sensor contacts into the passenger compartment and connect them to a regular two-position button. To implement this idea, you only need wires, a button and electrical tape or heat shrink insulation.

If you want to “unload” the button from unnecessary loads, you can install a relay in the circuit according to the diagram below.

In principle, there is nothing complicated either in the design of the fan itself or in its connection circuit. So in the event of any breakdown, you can safely proceed to self-repair.