What should be the gap between the piston and the cylinder

Content

To ensure high compression in the engine, and this greatly affects its efficiency and other abilities in terms of output, ease of starting and specific consumption, the pistons must be in the cylinders with a minimum clearance. But it is impossible to reduce it to zero, because of the different temperatures of the parts, the engine will jam.

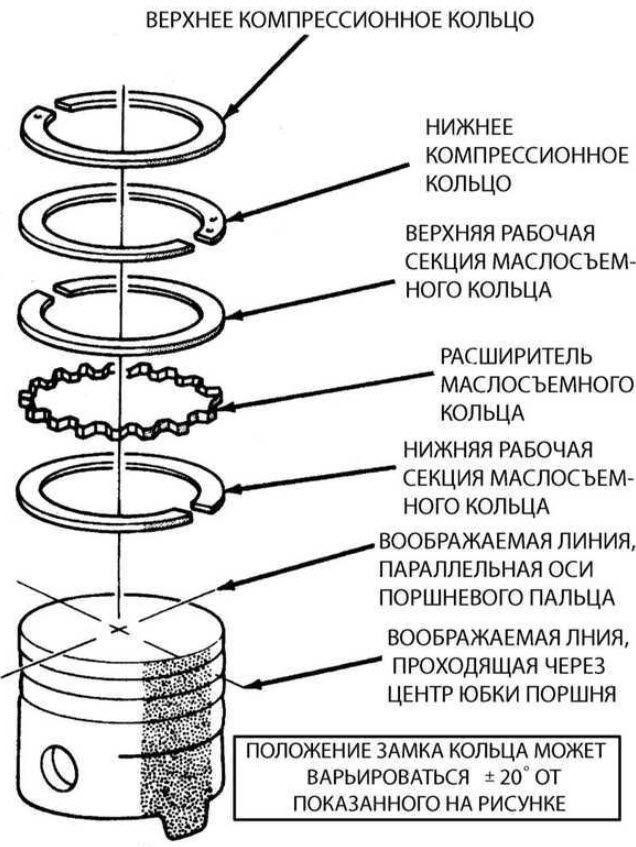

Therefore, the clearance is determined by calculation and strictly observed, and the necessary sealing is achieved by using spring piston rings as a gas and oil seal.

Why does the clearance between the piston and the cylinder change?

Car designers strive to make engine parts work in fluid friction mode.

This is a method of lubricating rubbing surfaces when, due to the strength of the oil film or the supply of oil under pressure and at the required flow rate, direct contact of the parts does not occur even under significant load.

Not always and not in all modes such a state can be maintained. Several factors influence this:

- oil starvation, the supply of lubricating fluid, as is done in the bearings of the crankshaft and camshafts, is not performed under pressure into the area between the piston and the cylinder, and other lubrication methods do not always give a stable result, special oil nozzles work best, but for various reasons put them reluctantly;

- poorly made or worn honing pattern on the surface of the cylinder, it is designed to hold the oil film and prevent it from completely disappearing under the force of the piston rings;

- violations of the temperature regime cause the zeroing of the thermal gap, the disappearance of the oil layer and the appearance of scoring on pistons and cylinders;

- the use of low-quality oil with a deviation in all significant characteristics.

It seems paradoxical, but the surface of the cylinder wears out more, although it is usually made of cast iron, it is a solid cast iron block or various dry and wet liners cast into the aluminum of the block.

Even if the sleeve is missing, the surface of the aluminum cylinder is subjected to special treatment, and a layer of a special hard wear-resistant coating is created on it.

This is due to a more stable pressure on the piston, which, in the presence of lubrication, almost does not remove metal from it during movement. But the cylinder is subject to rough work of spring rings with high specific pressure due to the small contact area.

Naturally, the piston also wears out, even if it happens at a slower rate. As a result of the total wear of both friction surfaces, the gap continuously increases, and unevenly.

Compliance

In the initial state, the cylinder is fully consistent with its name, it is a geometric figure with a constant diameter over the entire height and a circle in any section perpendicular to the axis. However, the piston has a much more complex shape, besides, it has heat-fixing inserts, as a result of which it expands unevenly during operation.

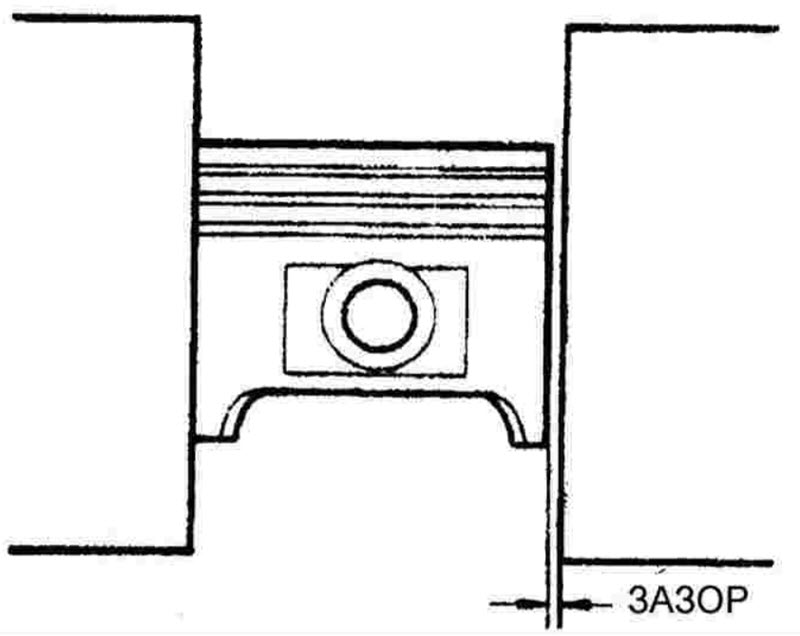

To assess the state of the gap, the difference in the diameters of the piston in the zone of the skirt and the cylinder in its middle part is selected.

Formally, it is considered that the thermal gap should be approximately 3 to 5 hundredths of a millimeter in diameter for new parts, and its maximum value as a result of wear should not exceed 15 hundredths, that is, 0,15 mm.

Of course, these are some average values, there are a great many engines and they differ both in different design approaches and in the geometric dimensions of the parts, depending on the working volume.

Result of gap violation

With an increase in the gap, and usually it is also associated with a deterioration in the performance of the rings, more and more oil begins to penetrate into the combustion chamber and is spent on waste.

Theoretically, this should reduce compression, but more often, on the contrary, it increases, due to the abundance of oil on the compression rings, sealing their gaps. But this is not for long, the rings coke, lie down, and the compression disappears completely.

Pistons with increased clearances will no longer be able to work normally and begin to knock. The knock of the piston is clearly audible on the shift, that is, in the upper position, when the lower head of the connecting rod changes the direction of its movement, and the piston passes the dead center.

The skirt moves away from one wall of the cylinder and, choosing a gap, hits the opposite one with force. You can’t ride with such a ringing, the piston can collapse, which will lead to a disaster for the entire engine.

How to check clearance between piston and cylinder

To check the gap, measuring equipment is used in the form of a micrometer and an inside gauge, this pair has an accuracy class that allows you to respond to every hundredth of a millimeter.

The micrometer measures the diameter of the piston in the zone of its skirt, perpendicular to the finger. The micrometer rod is fixed with a clamp, after which the inside gauge is set to zero while resting its measuring tip on the micrometer rod.

After such zeroing, the indicator of the caliper will show deviations from the piston diameter in hundredths of a millimeter.

The cylinder is measured in three planes, the upper part, middle and lower, along the piston stroke zone. Measurements are repeated along the axis of the finger and across.

As a result, the state of the cylinder after wear can be assessed. The main thing that is required is the presence of irregularities such as "ellipse" and "cone". The first is the deviation of the section from the circle towards the oval, and the second is the change in diameter along the vertical axis.

The presence of deviations of several acres indicates the impossibility of normal operation of the rings and the need to repair the cylinders or replace the block.

Factories tend to impose on customers a block assembly with a crankshaft (short block). But it often turns out to be much cheaper to repair with a bore, in severe cases - with a sleeve, with the replacement of pistons with new standard or oversized repair pistons.

Even not new engines with standard pistons, it is possible to accurately select clearances. To do this, the pistons are distributed into groups with a diameter deviation of one hundredth. This allows you to set the gap with perfect accuracy and ensure optimal motor performance and its future life.