PCV valve or how crankcase ventilation works in a car

Content

It is impossible to completely eliminate the gap between the piston and the cylinder in an internal combustion engine due to their different thermal expansion. There is always a danger of wedging, therefore, the thermal backlash of the piston is incorporated into the design, and depressurization is compensated by elastic split piston rings. But even they do not give one hundred percent seal against gases under pressure.

Meanwhile, the crankcase is practically hermetic, so the increase in pressure in it is inevitable, and as you know, this phenomenon is extremely undesirable.

Why do cars need crankcase ventilation?

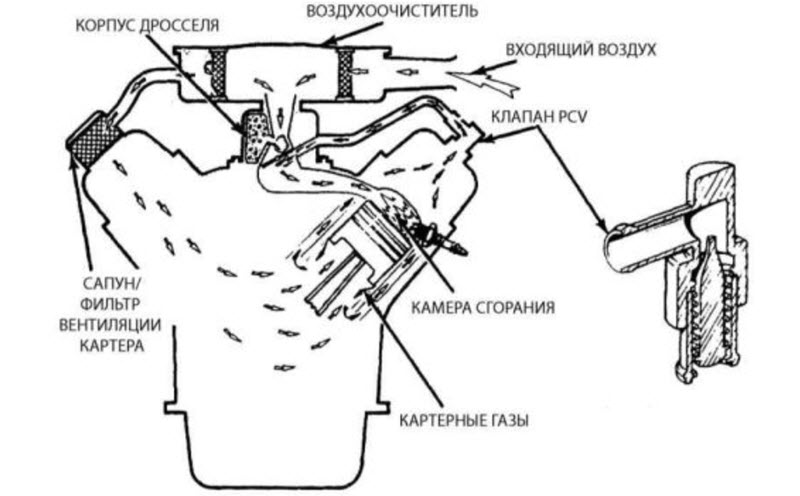

Passing through the gaps between the rings and their grooves in the pistons, as well as through their cuts, the exhaust gases, consisting of exhaust particles, unburned fuel and atmospheric contents, partially fall under the pistons into the engine crankcase.

In addition to them, there is always an oil mist in dynamic equilibrium, which is responsible for the lubrication of parts by splashing. The mixing of soot and other hydrocarbons with oil begins, which is why the latter gradually fails.

The process occurs constantly, its consequences are taken into account in the development and operation of engines.

The oil is changed regularly, and the additives present in it effectively retain and dissolve unwanted products until they are developed. But without taking additional measures in engines, especially those that have already worked for a long time, are partially worn out and pass a significant amount of gases through the piston group, the oil will fail too quickly.

In addition, pressure will rise sharply in the crankcase, which also carries a pulsating character. Numerous seals, especially the stuffing box type, will not withstand this. Oil consumption will increase, and the engine will quickly become dirty on the outside and violate even the lightest environmental requirements.

The way out will be crankcase ventilation. In its simplest form, it is a breather with a small oil labyrinth, where gases are partially released from oil mist, after which they are ejected by crankcase pressure into the atmosphere. The system is primitive, not suitable for modern engines.

Its shortcomings are indicative:

- the pressure in the crankcase is maintained along with the pulsations, although it is significantly reduced due to the release of gases through the breather;

- it is difficult to organize the regulation of crankcase gas flow;

- the system cannot work effectively in the entire range of revolutions and loads;

- release of gases into the atmosphere is unacceptable for environmental reasons.

Ventilation will work much better, where gas is taken forcibly, due to rarefaction in the intake manifold.

At the same time, the gases themselves enter the cylinders, where it is easy to organize their combustion with minimal emissions into the atmosphere. But even such an organization is imperfect due to the inconstancy of pressure in the throttle space.

Purpose of the PCV valve

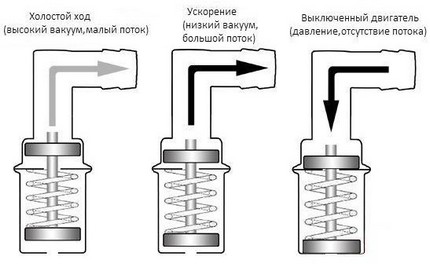

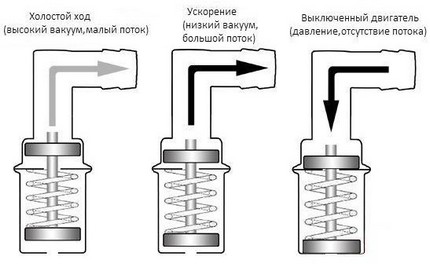

At idle and during engine braking (forced idling with increased speed), the vacuum in the intake manifold is maximum. The pistons tend to draw in air from the line with the filter, and the damper does not allow them to.

If you simply connect this space with a pipeline to the crankcase, then the flow of gases from there will exceed all reasonable limits, and separating oil from gas in such quantities will become a difficult task.

The opposite situation will occur at full throttle, for example, in fast acceleration or rated power. The flow of gases into the crankcase is maximum, and the pressure drop is practically minimized, determined only by the gas-dynamic resistance of the air filter. Ventilation loses its effectiveness exactly when it is most needed.

All needs can be adjusted using a special device - a crankcase ventilation valve, known by various abbreviations, most often PCV (fungus).

It is able to adjust the flow of gases in different modes, as well as prevent backflows from the manifold into the crankcase.

The device and principle of operation of the VKG valve

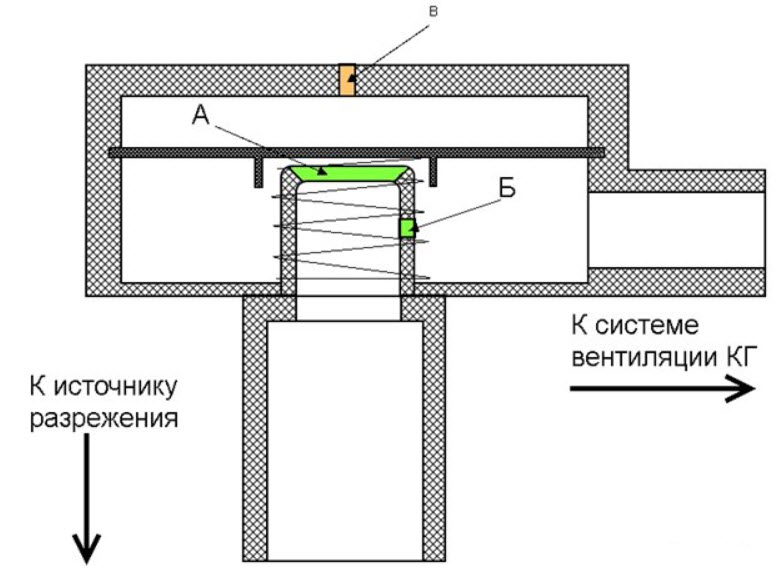

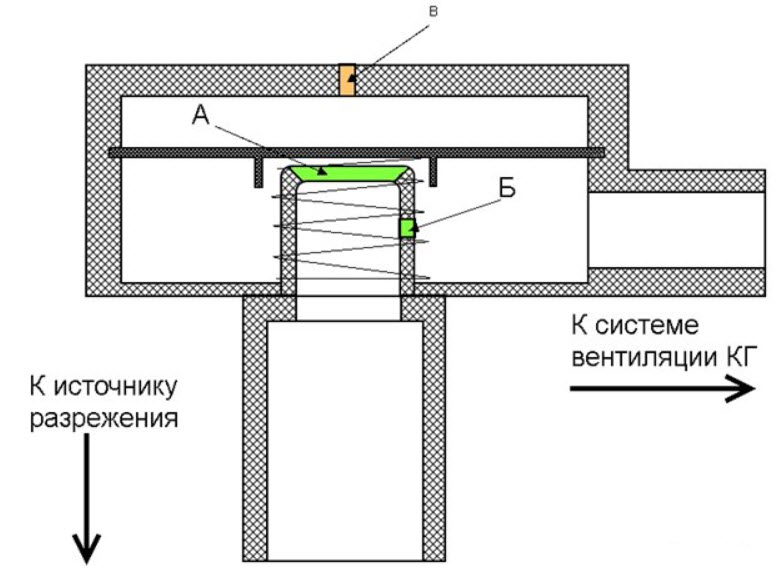

The valve can be arranged in various ways, using spring-loaded pistons (plungers) or flexible diaphragms (membranes) as an active element. But the general principle of operation for all devices is the same.

The valve has an inverse relationship between its capacity and pressure drop.

- When the throttle is fully closed, the vacuum is maximum. The PCV valve responds by opening a small amount, which ensures minimal gas flow through it. At idle, no more is required. At the same time, the oil separator of the ventilation system successfully copes with its duties, oil does not enter the collector, and there is no consumption for waste.

- In medium load conditions with a partially open throttle, the vacuum will drop, and the valve performance will increase. The crankcase gas consumption increases.

- At maximum power and high speeds, the vacuum is minimal, since there is practically no interference with the incoming air. The ventilation system should show its capabilities to the maximum, and the valve ensures this by opening completely and not interfering with the release of gases beyond the open throttle.

- Backfires can occur in the manifold, which are dangerous for flammable blow-by gases. But the valve will not allow fire to penetrate into the ventilation, instantly slamming due to the reverse pressure drop.

At the same time, the design of the valve is extremely simple and contains nothing but a spring and stems with plungers or a membrane in a plastic case.

Symptoms of a stuck PCV

In case of failure, the valve can jam in any position, after which the engine will not be able to work normally in all other modes.

By itself, ventilation will not directly affect performance, it will affect long-term problems, oil wear and blown crankcase seals. But the air passing through the ventilation system, and hence through the valve, is already taken into account in the settings of the engine management system. Hence the problems with the composition of the mixture, and in certain modes.

The mixture can either be enriched when the valve is constantly closed, or depleted if it is stuck in the open position. On a lean mixture, the engine starts worse and does not give off the usual power.

Rich will cause problems with fuel consumption and deposits on engine parts. It is possible that the self-diagnosis system will trigger with the appearance of errors in the composition of the mixture and the operation of oxygen sensors.

How to check the PKV valve

The easiest way to check the valve is to replace it with a known good one. But in the process of working on engine diagnostics with a scanner connected, it may be faster to assess its condition by changing the position of the idle speed controller stepper motor.

There should be a difference of approximately 10% between loose breather modes, i.e. no valve, with a valve in the gas circuit, and completely shut off ventilation.

That is, a normally working valve divides the idle air approximately in half, giving an average flow rate between the closed and open breather.

Watch this video on YouTube

Servicing the crankcase ventilation valve

Extending the life will help periodic cleaning, which can be done at every third oil change. The valve is dismantled and thoroughly washed on both sides with an aerosol carburetor cleaner.

The end of the flushing procedure will be the release of clean liquid from the housing. After the operation, the valve must be checked as it may already be damaged, and flushing will remove the sealing layer of deposits.